Seawater desalination system recovering latent heat of steam condensation

A technology of steam condensation and steam condenser, which is applied in the fields of seawater desalination and clean energy utilization, which can solve problems such as the recovery and utilization of steam condensation latent heat, and achieve the effects of improving energy conversion efficiency, avoiding energy waste, and improving energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The seawater desalination system for recovering latent heat of steam condensation involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0029]

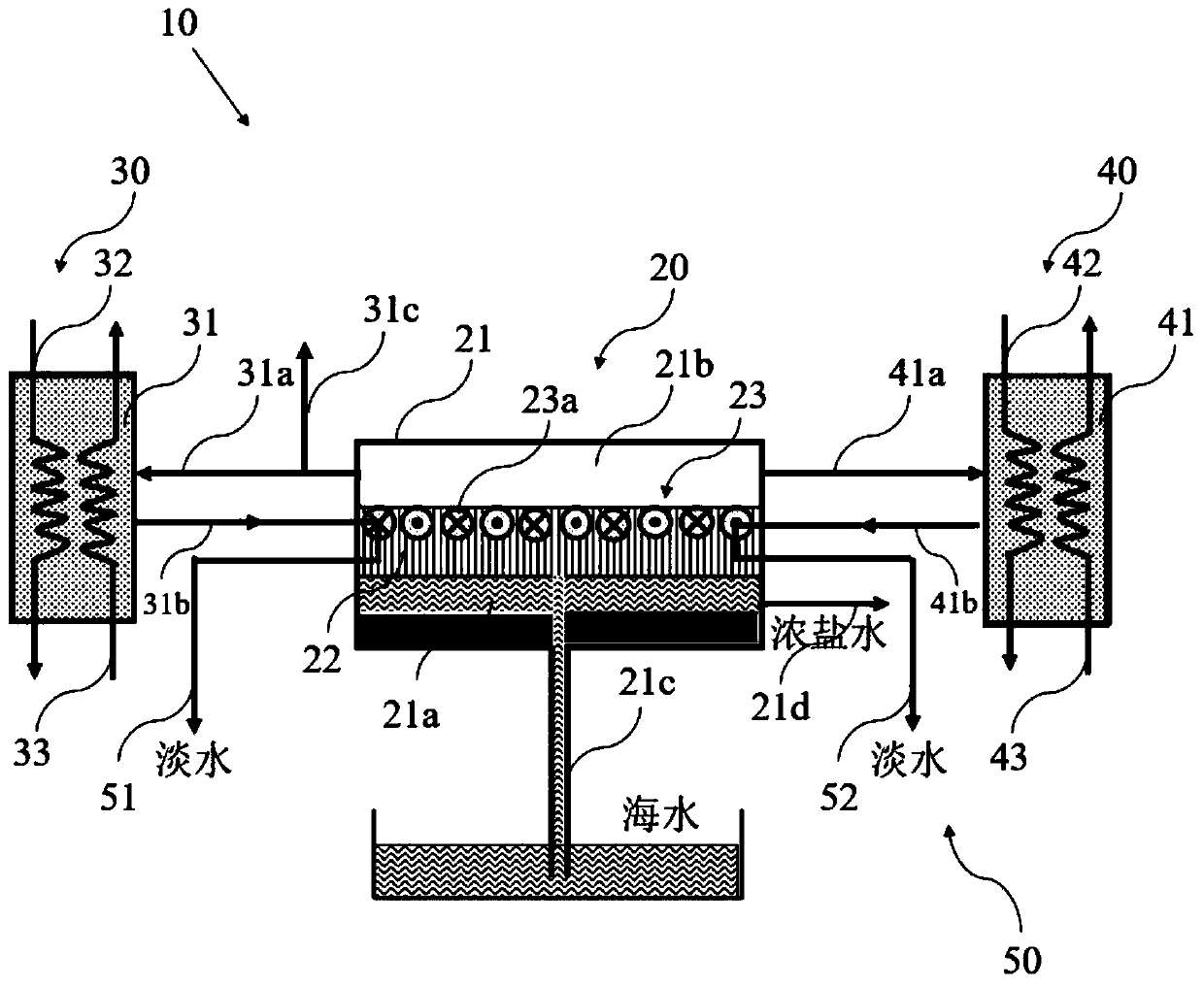

[0030] Such as figure 1 As shown, the seawater desalination system 10 for recovering the latent heat of steam condensation includes: a capillary-driven evaporation device 20 , secondary steam generators 30 and 40 , a fresh water discharge pipe 50 , and a fresh water collector (not shown in the figure).

[0031] The capillary-driven evaporation device 20 includes: a housing 21 , a capillary evaporation core 22 , and a vapor condenser 23 .

[0032] The housing 21 is made of POM plastic with a thermal conductivity lower than 0.3W / (m·K) and resistant to seawater corrosion. It has a good thermal insulation and sealing effect, and can effectively prevent heat loss and steam condensation. The shell 21 is divided into upper and lower cavities by the capillary evaporation c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com