Plate blank scale filtering device

A filter device and slab technology, which is applied in the field of filter devices, can solve problems such as interference, insufficient stability of slab weight control, product density fluctuations, etc., and achieve the effect of eliminating abnormal weight fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

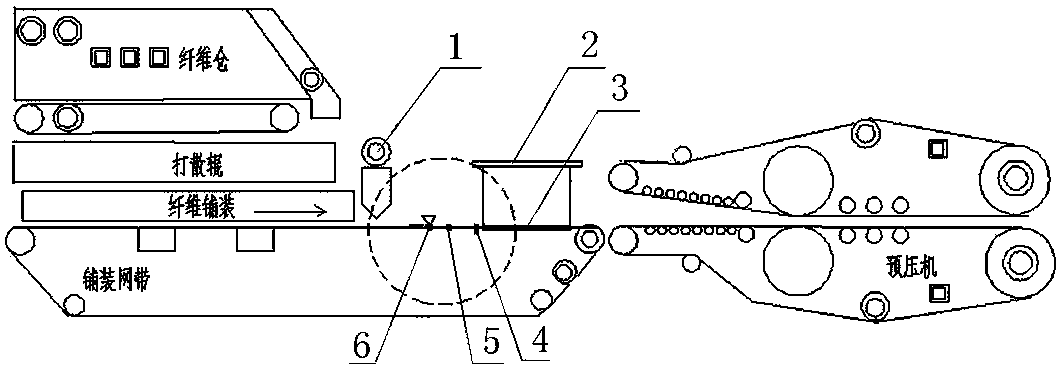

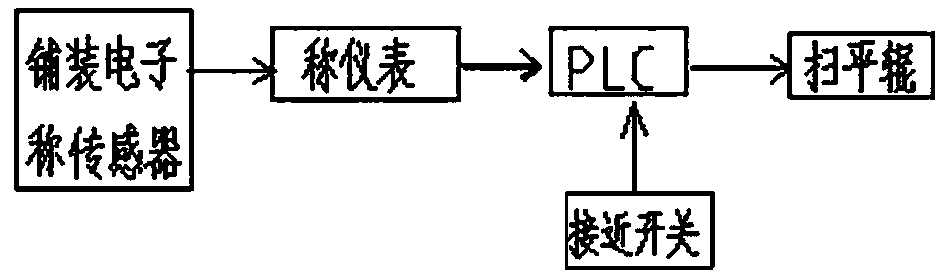

[0012] Such as figure 1 As shown, in the slab paving production line, the fibers are sent from the fiber bin to the paving head, and then transported through the paving mesh belt. The fiber height and surface smoothness are controlled by the sweeping roller 1 first, and then sent to the pre-pressing machine for pre-pressing . In this process, the fiber is transported from the paving mesh belt, and the weight of the fiber passing through is controlled by the lifting of the leveling roller 1, and this weight is sensed by the subsequent paving electronic weighing sensor and then passed to the equipment through the weighing instrument The PLC on the machine can control the lifting and lowering of the sweeping roller and control the weight of the fiber. Because there is a mesh belt joint 4 on the pavement mesh belt, every time it runs through the pavement electronic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com