Spring test device

A testing device and spring assembly technology, applied in measurement devices, elasticity testing, mechanical component testing, etc., can solve problems affecting the overall quality of production equipment and economic development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

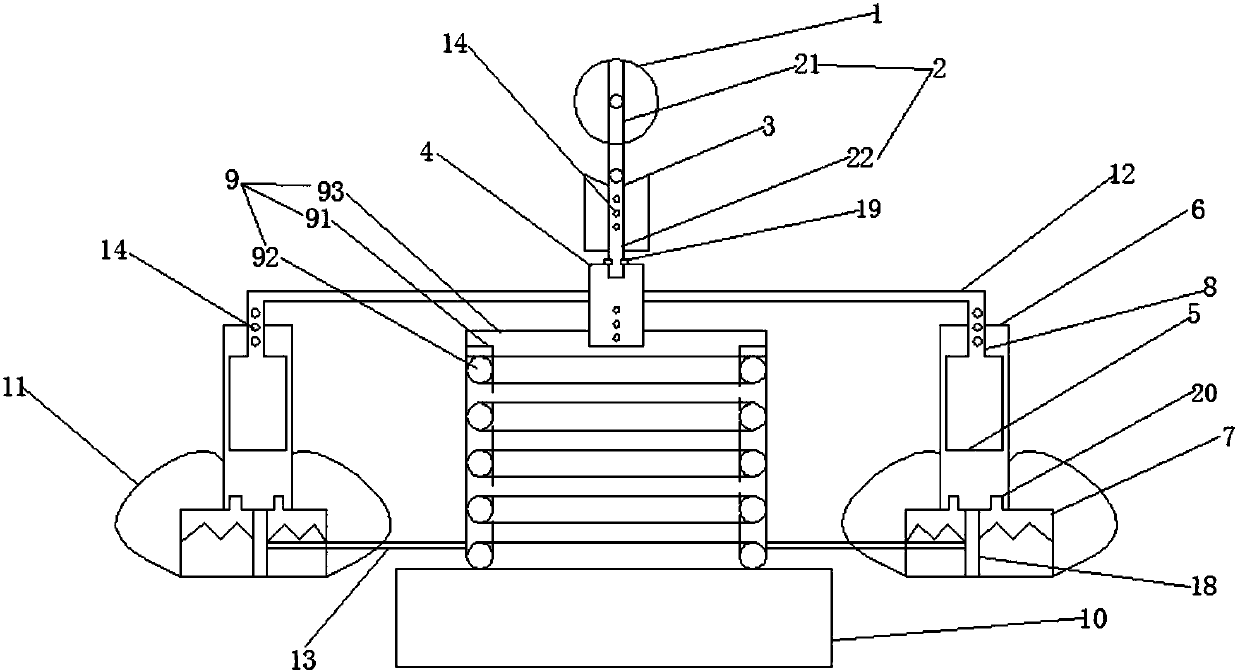

[0034] Such as figure 1 As shown, a spring testing device according to a preferred embodiment of the present invention includes a driving module, a hydraulic circuit module and a loaded force receiving module. Force module connection. The spring testing device of the present invention drives the hydraulic circuit module under the drive of the driving module, so that the spring can simulate the actual working conditions to load the spring in the axial direction under the action of the loading force module, and test the strength of its stiffness and longevity.

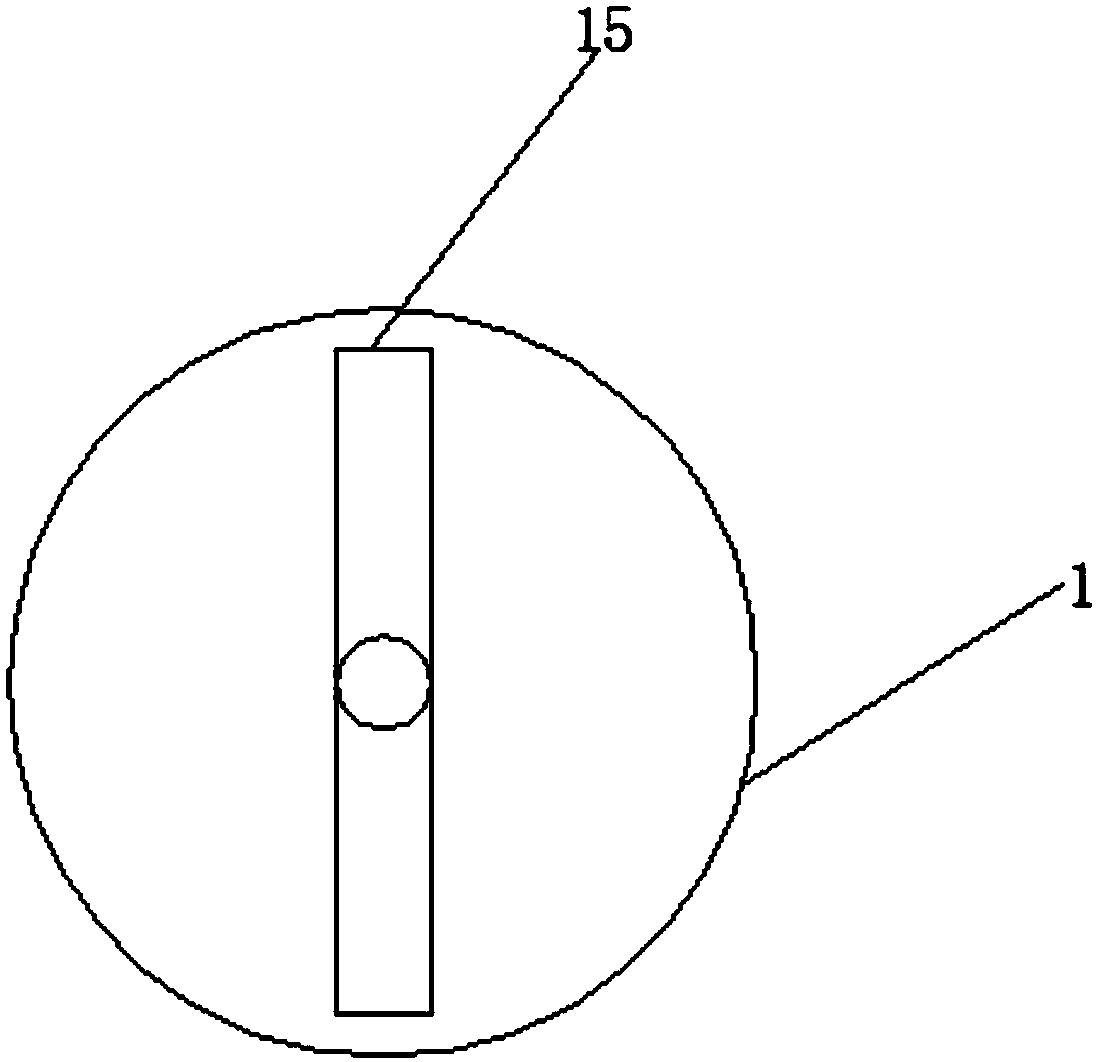

[0035] Specifically, the drive module includes a turntable 1, a push rod 2, a fixed stand 3 and a connecting block 4, the upper end of the push rod 2 is connected with the turntable 1, the lower end of the push rod 2 is connected with the fixed stand 3, and the bottom end of the push rod 2 Connected to connection block 4.

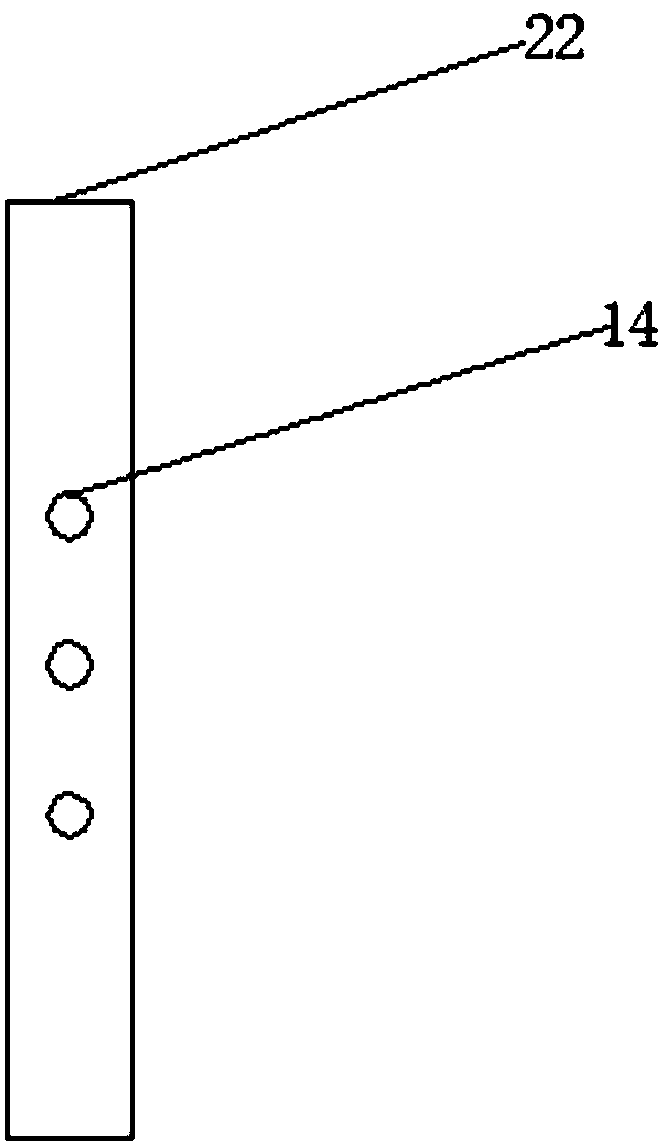

[0036] Such as figure 2 As shown, the push rod 2 includes an upper push rod 21 and a lower pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com