Insulation defect detection device and method for electrical device

A technology for electrical equipment and insulation defects, applied in the direction of testing dielectric strength, etc., can solve the problems of increasing the risk of equipment operation, difficulty in finding small-scale concentrated, malignant faults, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific implementation manners described here are only used to illustrate and explain the implementation manners of the present invention, and are not intended to limit the implementation manners of the present invention.

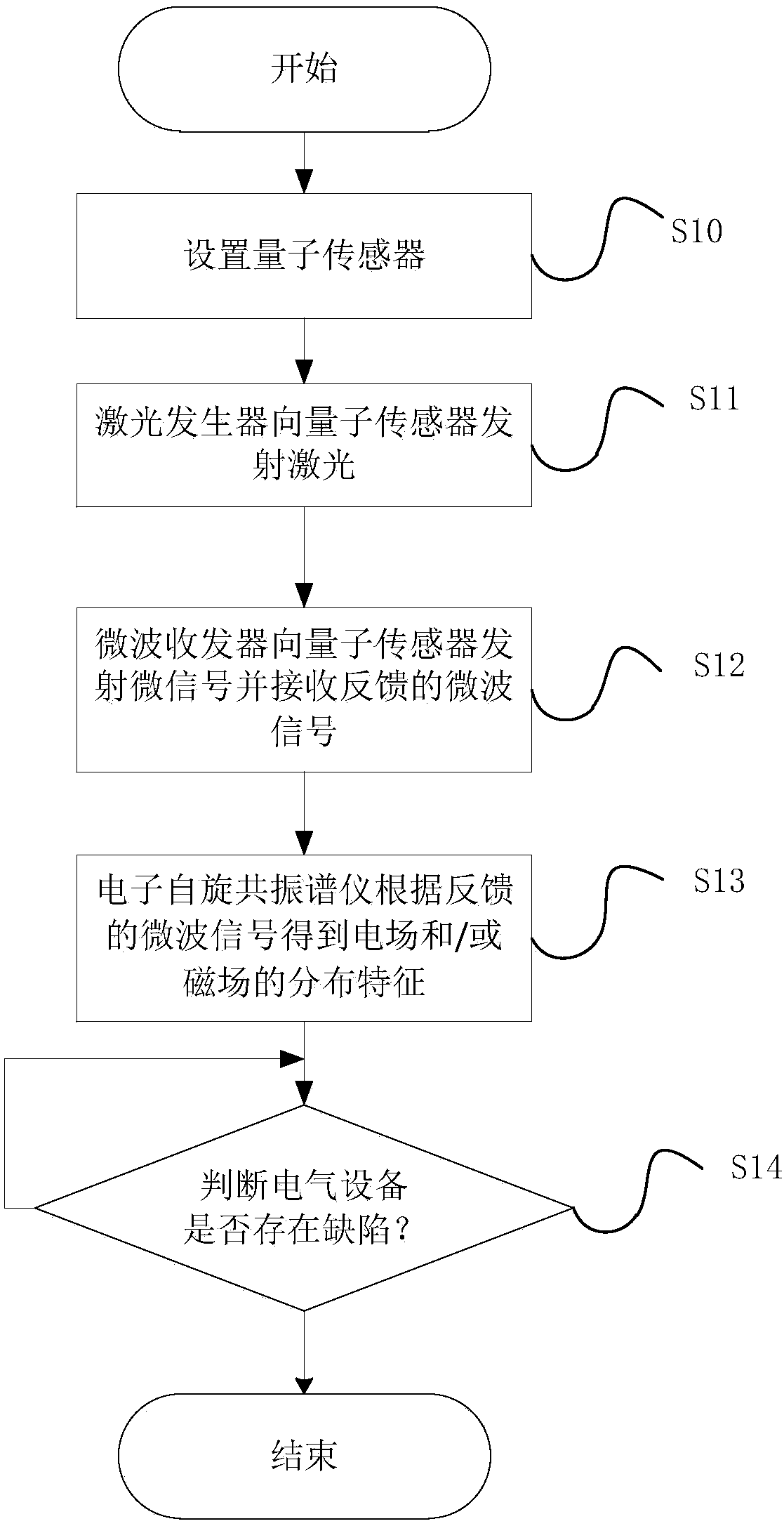

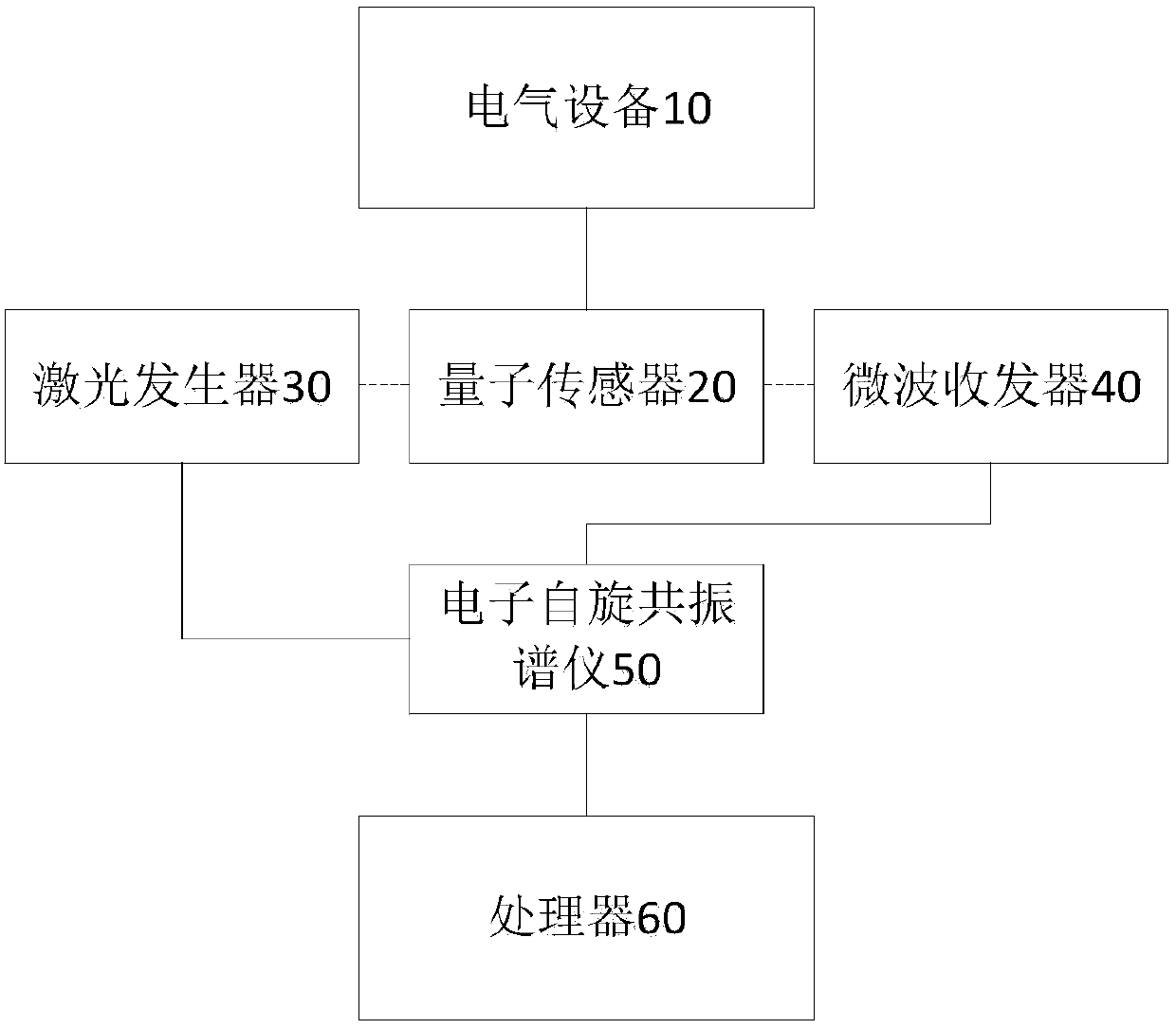

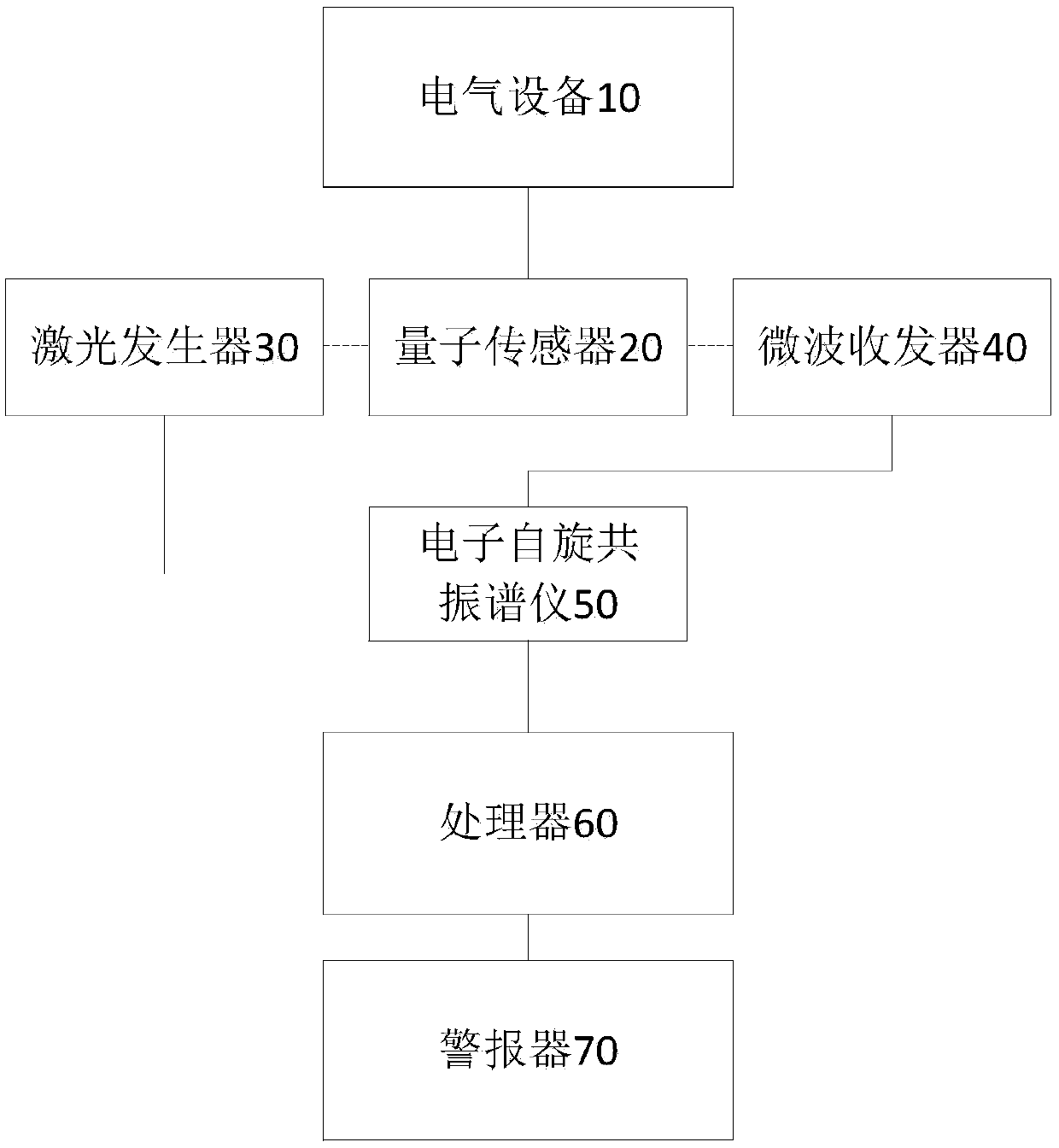

[0038] figure 1 is a flowchart of a method for detecting insulation defects of electrical equipment according to an embodiment of the present invention. In the figure, the method may include the following steps:

[0039] In step S10, the quantum sensor 20 is set. In this embodiment, the position of the quantum sensor 20 can be determined according to the electrical equipment that actually needs to be detected. Electrical equipment may include, for example, current transformers, transformer bushings, or other equipment that needs to be judged whether there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com