Particle concentrator

A concentration device and particle technology, applied in the direction of measuring devices, dispersed particle separation, particle size analysis, etc., can solve problems such as difficulty in concentration, unsuitability, and difficulty in nano-aerosol concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

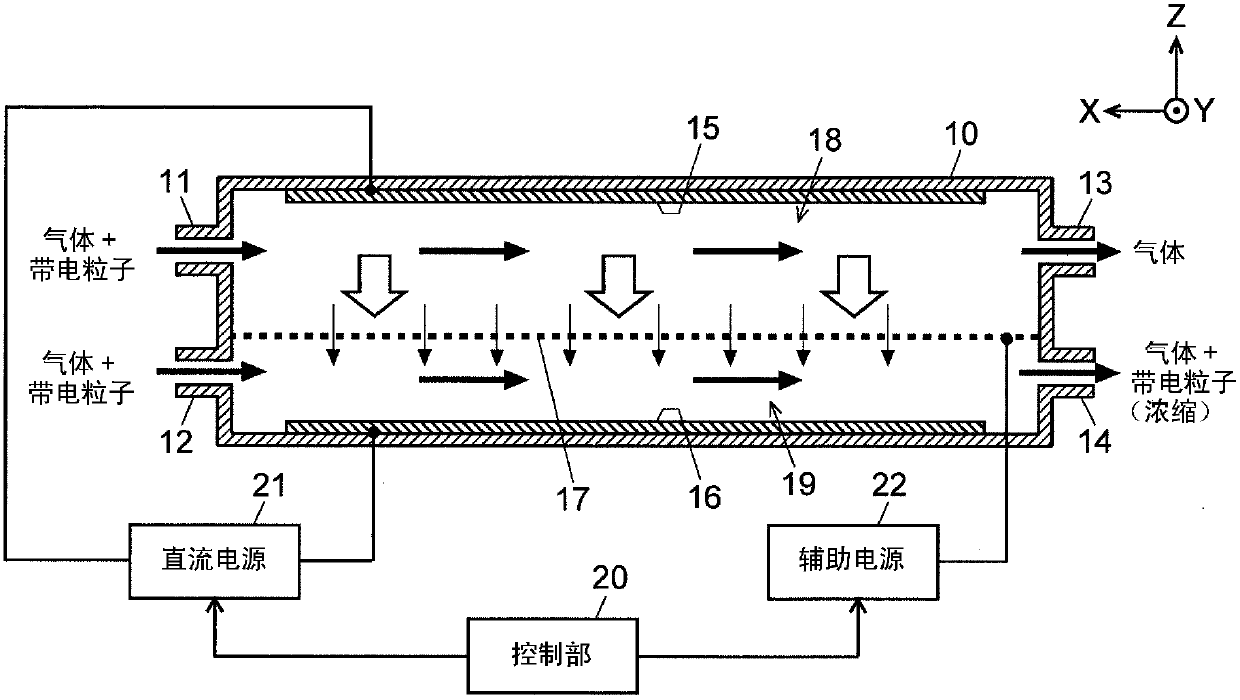

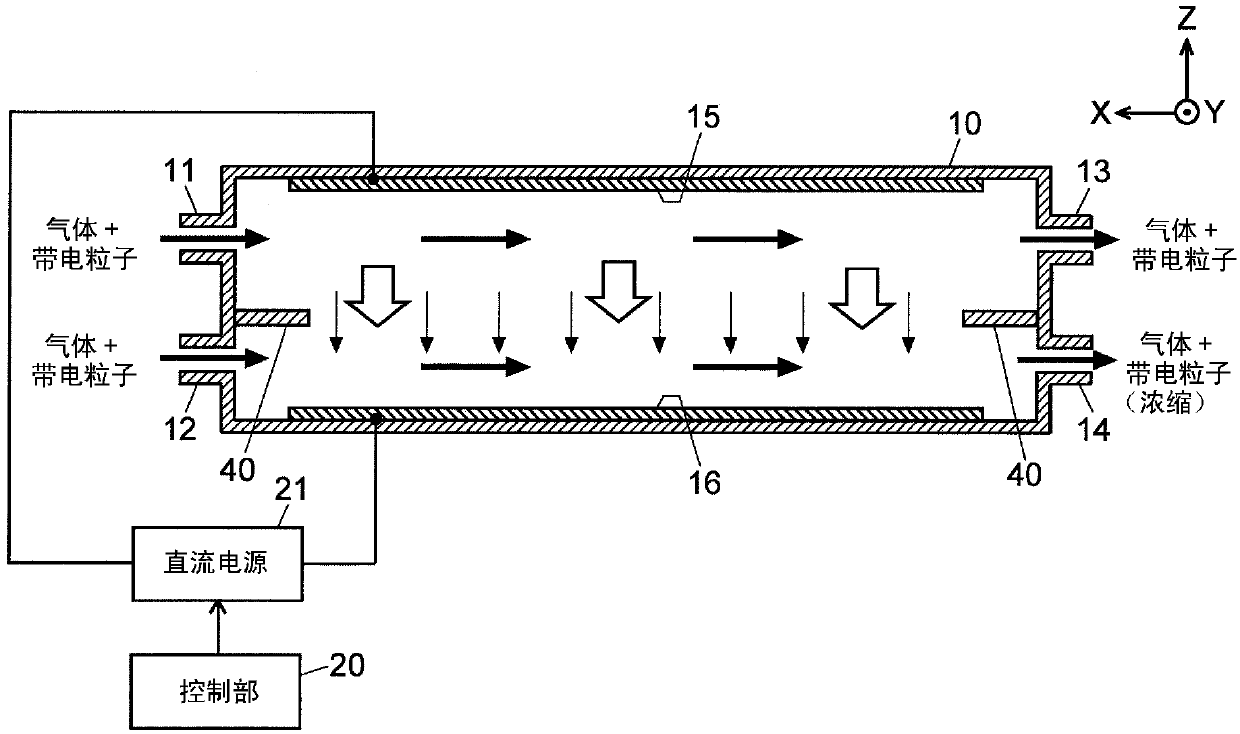

[0042] Below, refer to figure 1 The particle concentrator of the first embodiment of the present invention will be described. figure 1 It is a longitudinal sectional view showing a schematic structure of the particle concentrator of this embodiment.

[0043] In addition, for the convenience of explanation, the figure 1 The X direction in is set to the left, the Y direction is set to the front, and the Z direction is set to the top, thereby defining front and rear, up and down, and left and right. This is described later figure 2 , image 3 and Figure 6 is also the same.

[0044] The particle concentrating device of the first embodiment has a substantially rectangular parallelepiped housing 10, and first openings serving as openings for letting gas flow into the housing 10 from the outside are arranged along the left side of the housing 10 along the vertical direction. A gas introduction port (corresponding to the gas introduction part in the present invention) 11 an...

no. 2 Embodiment

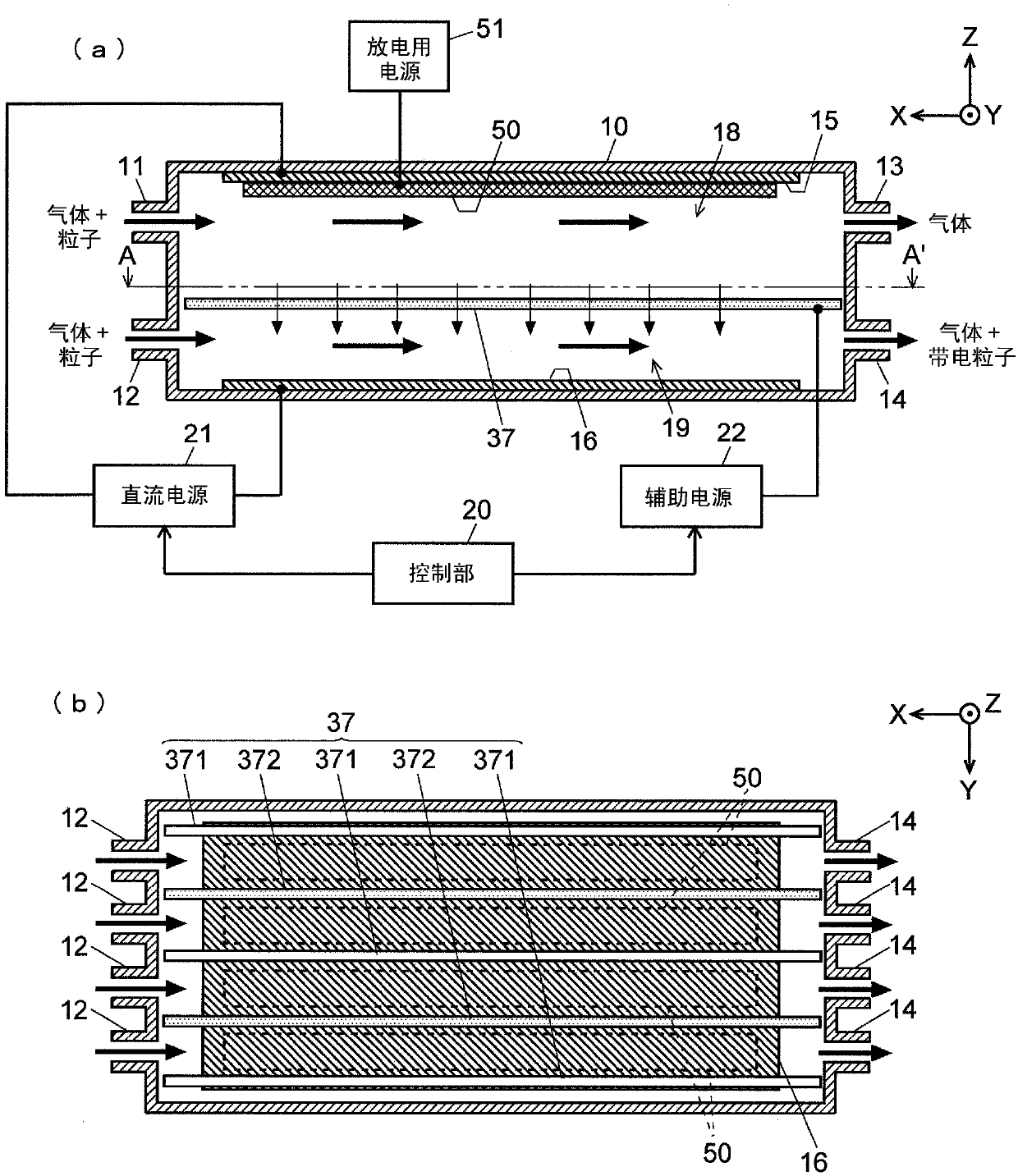

[0059] Next, refer to image 3 and Figure 4 A particle concentrator according to a second embodiment of the present invention will be described. image 3 (a) is a longitudinal sectional view showing a schematic structure of the particle concentrator of the second embodiment, image 3 (b) is image 3 A-A' line sectional view in (a). Figure 4 It is a perspective view of the filter 37 in the particle concentrator of the second embodiment. Also, yes image 3 , Figure 4 Components that are the same as or equivalent to those of the device of the first embodiment are given the same reference numerals as those of the first embodiment.

[0060] In the particle concentrating device of the first embodiment described above, the carrier gas containing the particles charged outside the case 10 is supplied into the housing 10, but in the particle concentrating device of the second embodiment, at least through the first The gas inlet 11 supplies carrier gas containing uncharged unch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com