Rotary mechanical fixture matched with robot

A technology of rotating machinery and robots, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of difficult to guarantee clamping accuracy, affecting product processing quality, intermittent automation programs, etc., to achieve convenient control and docking, convenient implementation, Clamping for precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

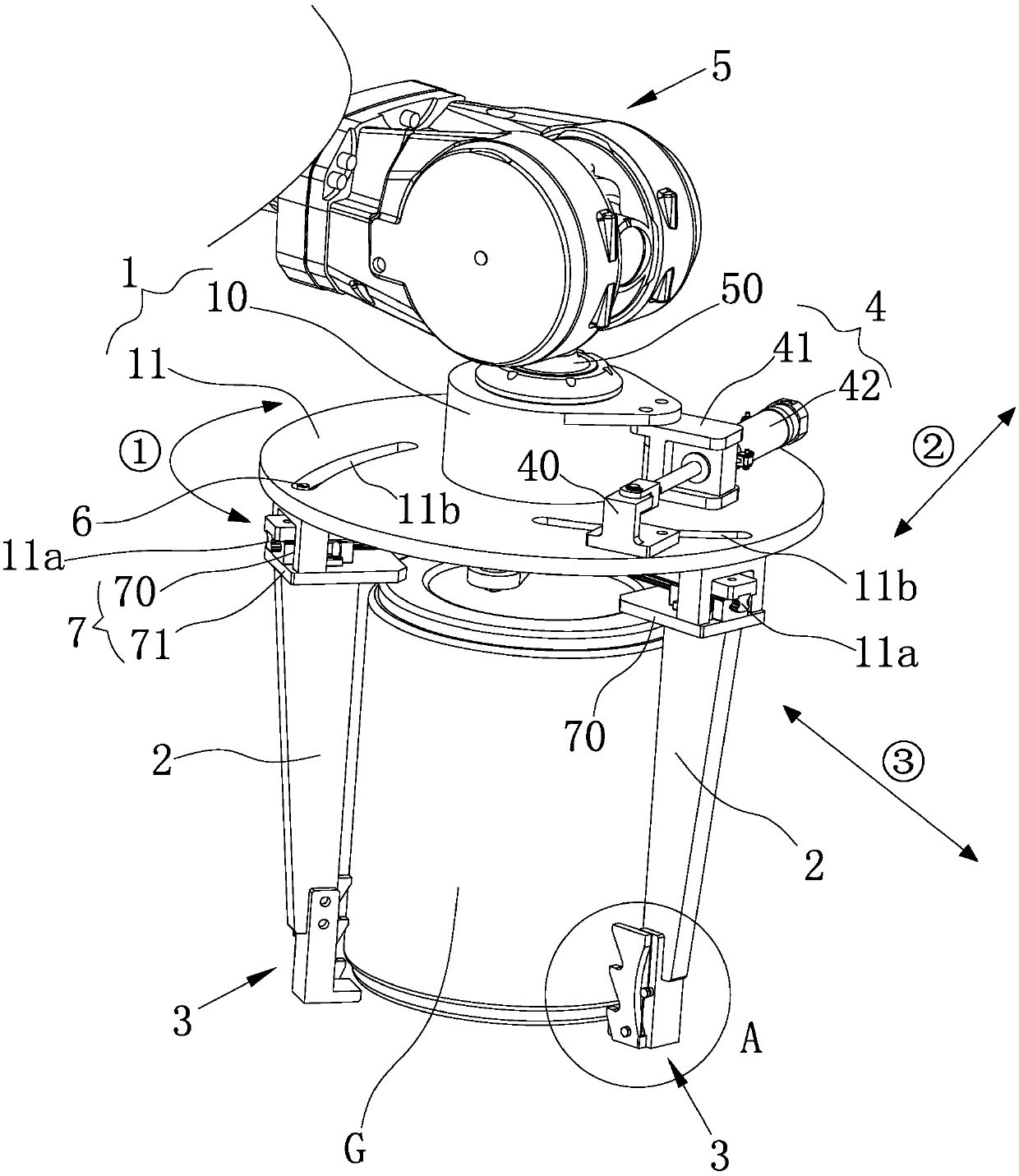

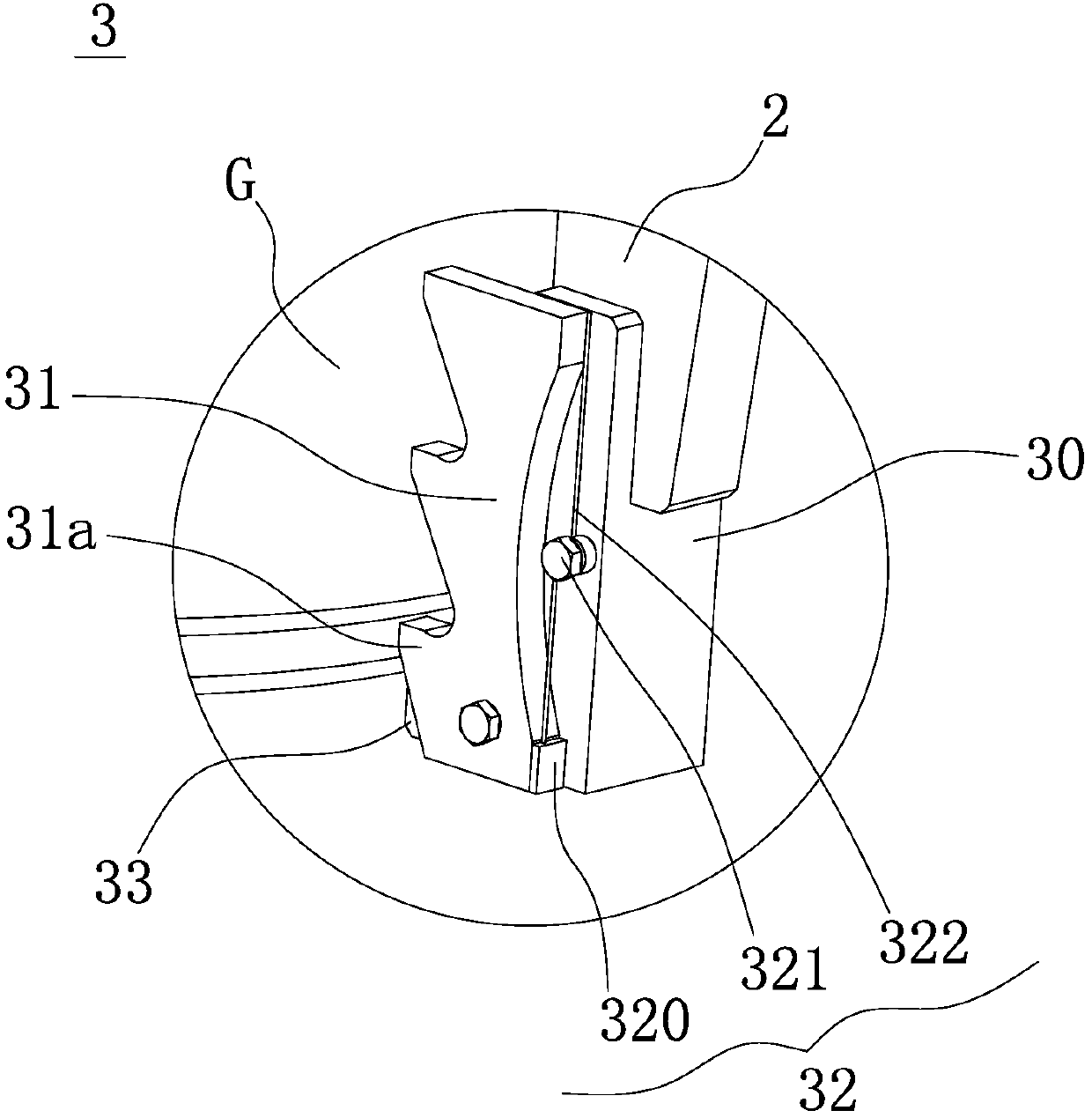

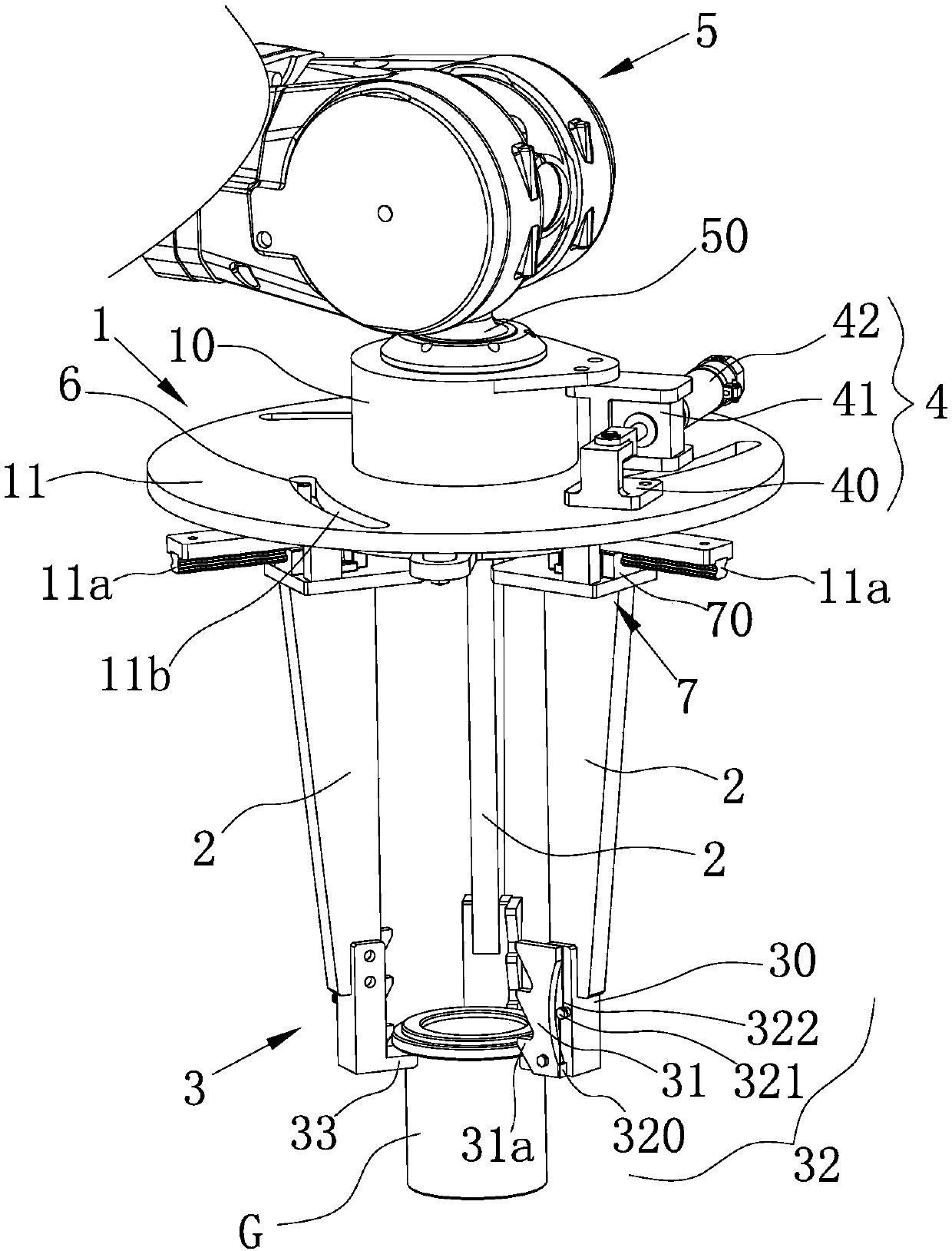

[0028] see Figure 1 to Figure 3 As shown, the rotary mechanical gripper matched with the robot provided in this embodiment includes a connection base 1 , a gripper arm 2 , a gripper jaw 3 , and a driving mechanism 4 .

[0029] Specifically, the connecting seat 1 includes a connecting portion 10 connected to the connecting shaft 50 of the robot 5 , and a turntable 11 arranged on the connecting portion to rotate around the center of the connecting shaft 50 .

[0030] On the turntable 11, there are a plurality of tracks 11a extending radially along the turntable 11 corresponding to the clamp arms 2, and track grooves 11b on the turntable 11 corresponding to the plurality of tracks 11a. When 11 rotates, the clip arm 2 can slide relatively along the track 11a and the track groove 11b.

[0031] In this example, there are three clamping a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com