Garbage can facilitating putting and classification

A technology of waste bins and main bodies, which is applied in the field of waste bins that are easy to put and sort, can solve the problems of inability to automatically classify waste and inconvenience in putting waste, so as to improve the probability of accurate input, reduce work intensity, and avoid accidental injuries. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

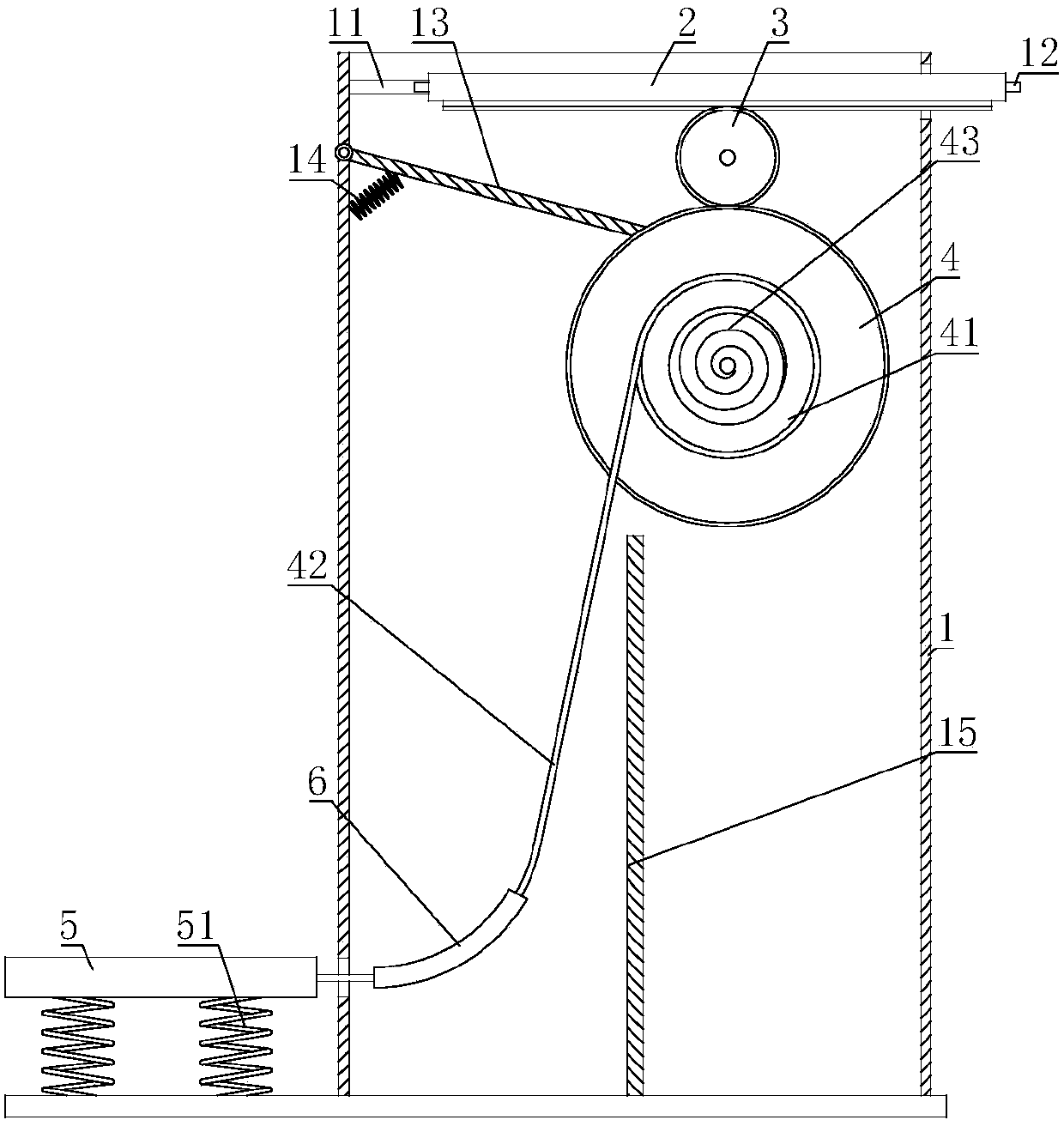

[0022] A garbage can for easy throwing and sorting, including a garbage can main body 1, a chute 11 is provided on the top of the main body 1 of the garbage can, a slider 12 is sleeved inside the chute 11, and a top cover 2 is fixed on the slider 12. The top cover 2 is connected with a rack 21, the rack 21 is meshed with a reversing gear 3, and the reversing gear 3 is meshed with a driving gear 4. A rotating ring 41 is fixed on the rotating ring 41, and a pulling rope 42 is wound around the rotating ring 41. One end of the pulling rope 42 is fixed with the rotating ring 41, and the other end of the pulling rope 42 is connected with a foot pedal 5. A spring 51 is connected between them; a torsion spring 43 is connected between the rotating ring 41 and the main body of the waste bin 1, and the winding direction of the pulling rope 42 is opposite to that of the torsion spring 43; A support spring 14 is connected between the middle section of the guide plate 13 and the main body o...

Embodiment 2

[0025] On the basis of the first embodiment, an elbow 6 is installed on the main body 1 of the waste bin, and the pull rope 42 is sleeved in the elbow 6 .

[0026] When the pull rope 42 moves, the pull rope 42 slides in the curved pipe 6, and the pull rope 42 will not be cut during the movement.

Embodiment 3

[0028] On the basis of Embodiment 1 or Embodiment 2, the diameter of the rotating ring 41 is 1 / 4 to 3 / 4 of the diameter of the driving gear. When the diameter of the rotating ring 41 is 1 / 4 to 3 / 4 of the diameter of the driving gear 4, the pull rope 42 moves a small distance at one end, the transmission ratio is appropriate, and the top cover 2 can be moved away in a large range to ensure that the user can The garbage is thrown into the garbage can main body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com