Lens headlamp reflecting bowl

A reflector, lens technology, applied in reflectors, headlights, lighting and heating equipment, etc., can solve the problems of uneven light reflection, affecting the light output of lens headlights, increasing light loss, etc., to achieve uniform reflected light, light The effect of uniformity and light loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

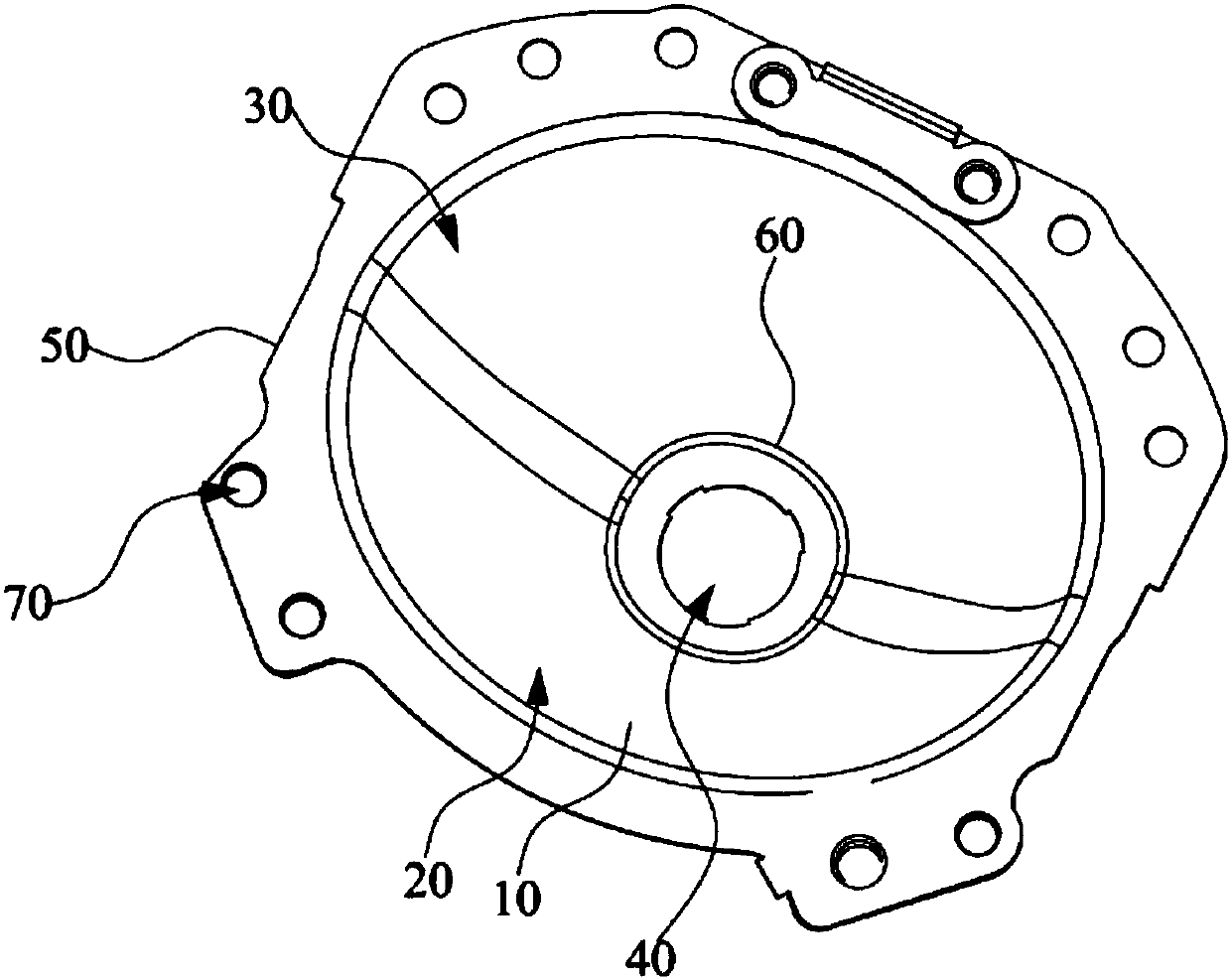

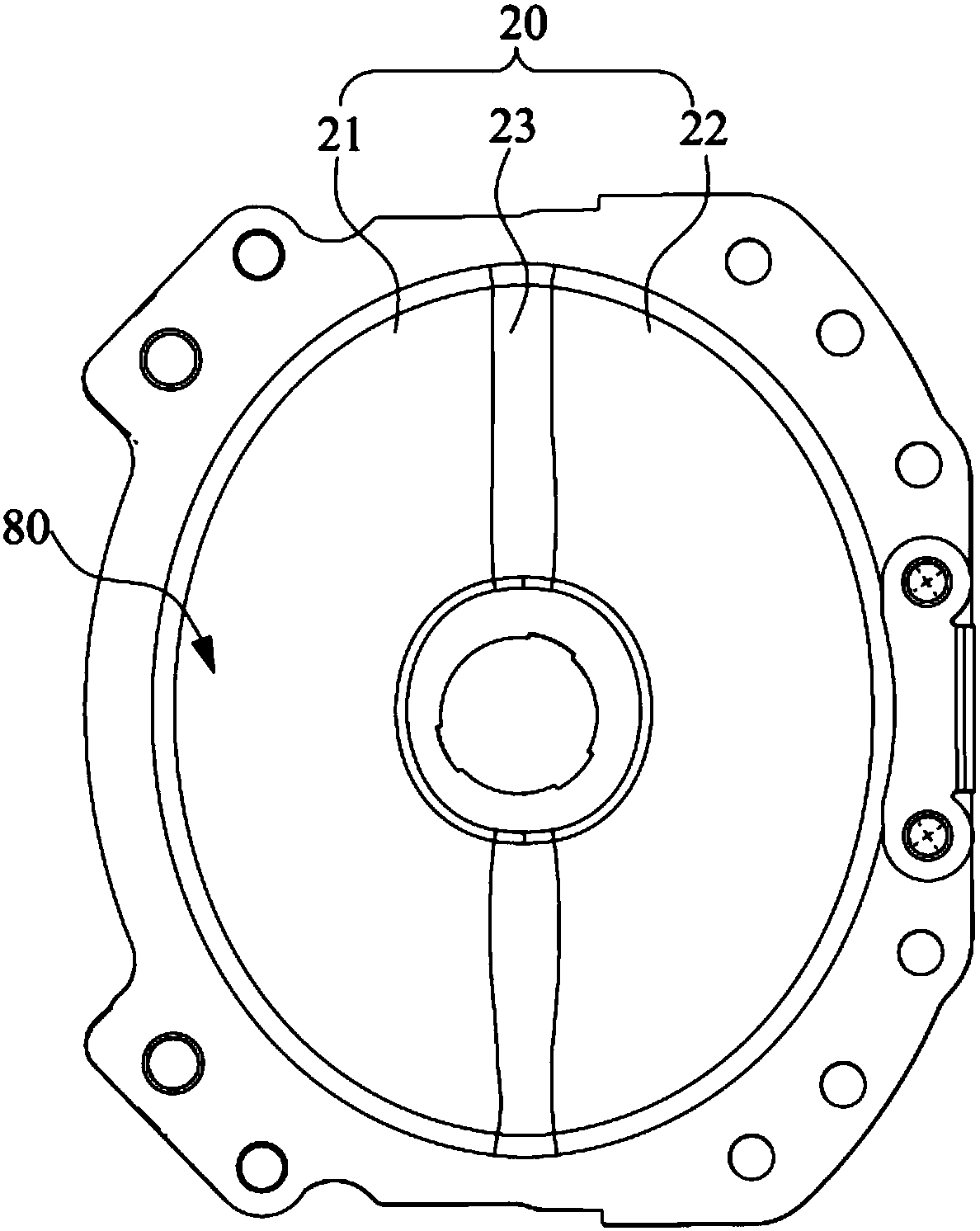

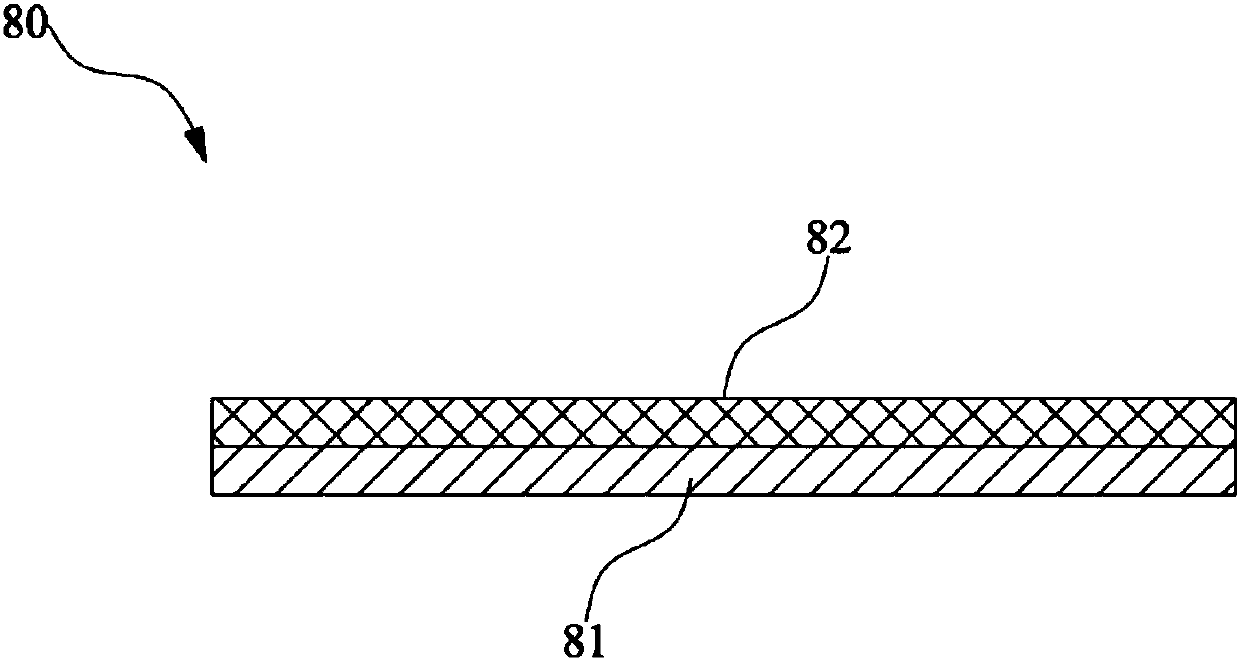

[0023] Please refer to figure 1 , figure 1 It is a three-dimensional view of the reflection bowl of the lens headlight according to the embodiment of the present application. As shown in the figure, a reflector bowl for lens headlights includes a bowl wall 10, the bowl wall 10 has a concave bowl surface 20 and a first bowl mouth 30 and a second bowl mouth 40 located on both sides of the bowl surface 20, the bowl surface 20 has a reflective layer 80, and the reflective layer 80 is configured as a light-reflecting composite material; the outer flange portion 50 is arranged on the outside around the first bowl mouth 30; the inner flange portion 60 is arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com