Estimation method for analyzing ultimate bearing capacity of bends

A technology of ultimate bearing capacity and pipe bending, which is used in computing, special data processing applications, instruments, etc., can solve the problems of complex calculation process, difficult engineering application, large amount of calculation, etc., and achieve the effect of high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

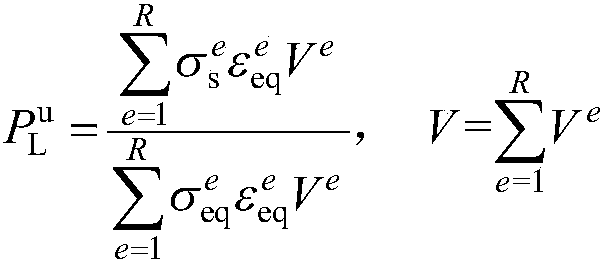

[0057] This embodiment is a specific example of the method for estimating the analysis of the ultimate bearing capacity of an elbow, including the following steps:

[0058] (1) Establish the analysis model of the elbow structure:

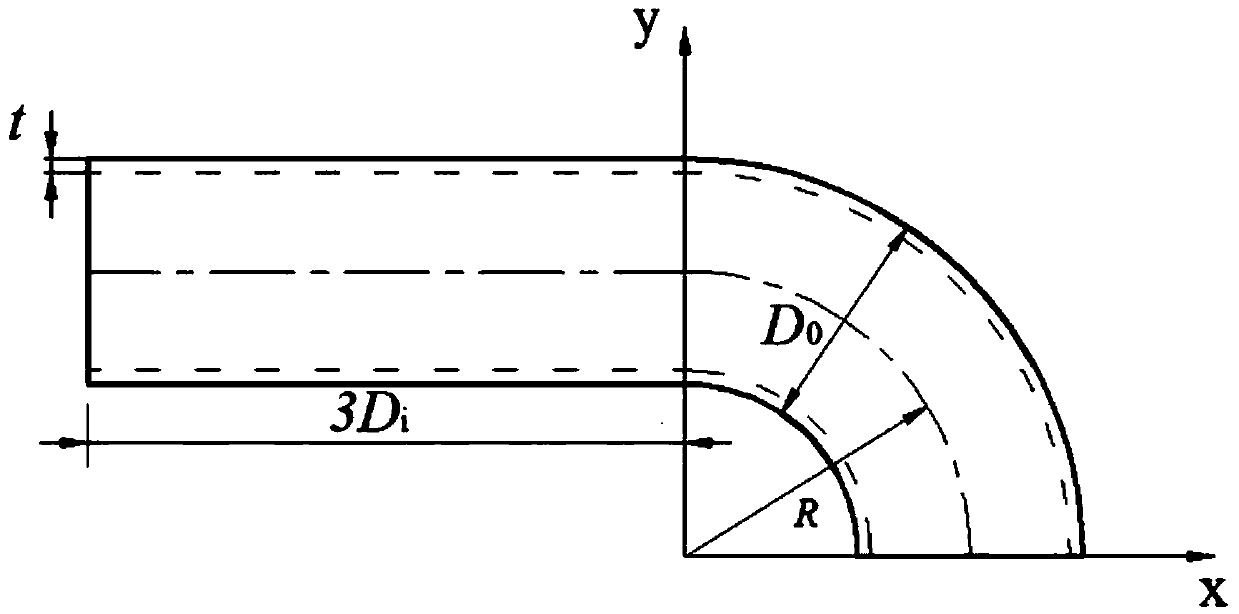

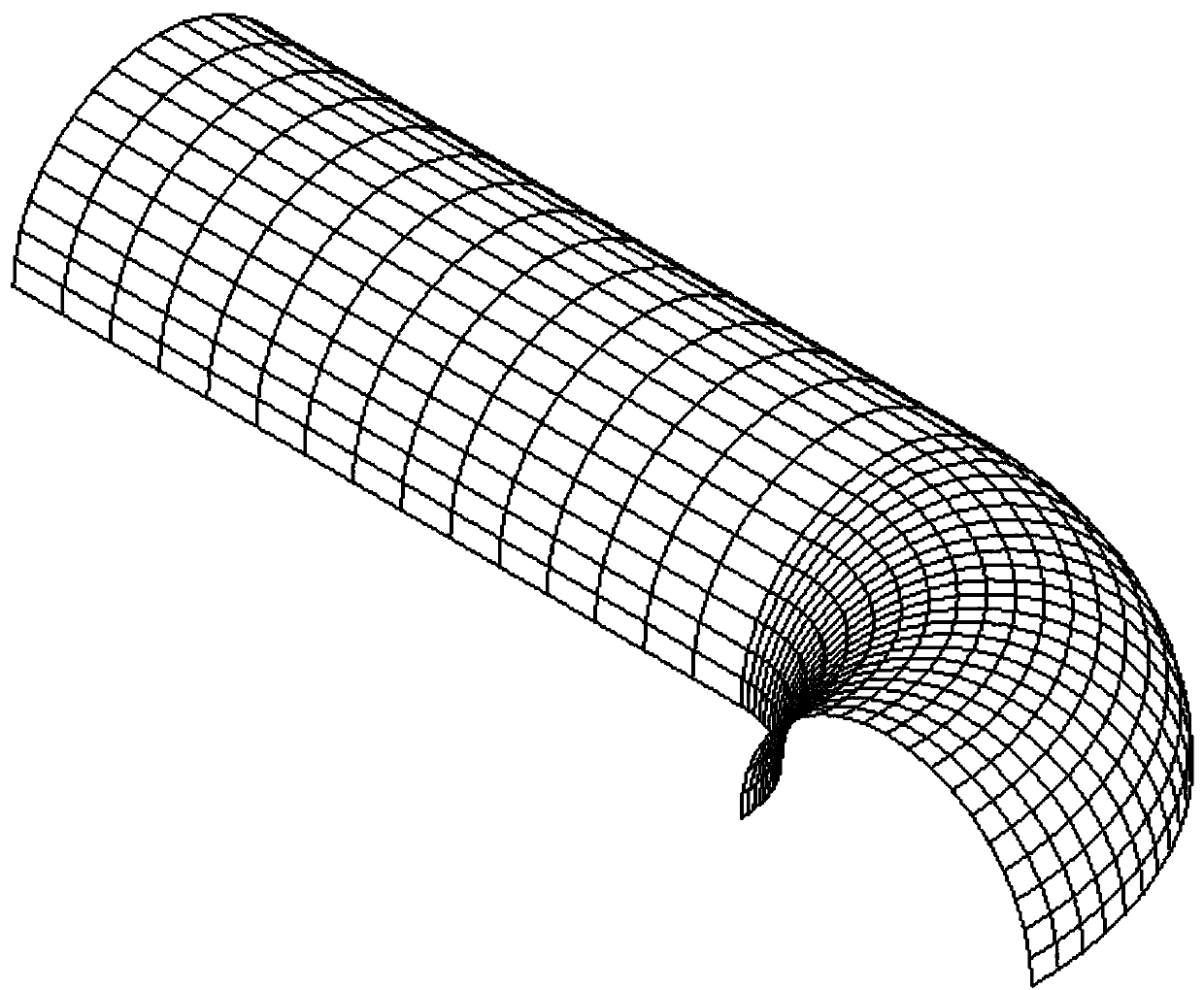

[0059] The geometric dimensions of a 90° elbow are shown in Table 1, and the material parameters are shown in Table 2. Bearing the internal water pressure P, the right end of the elbow is fixedly constrained, and the left end is not constrained. The calculation model of the elbow is as follows figure 1 As shown, the ANSYS software is used for modeling, and the shell element is used for simulation. The finite element mesh of the elbow is as follows figure 2 .

[0060] Table 1 Bend Pipe Geometric Dimensions

[0061] parameter

Outer radius D O / mm

inner radius D I / mm

Bending radius R / mm

value

104

86.7

86.7

[0062] Table 2 Bend material parameters

[0063] parameter

Yield strength σ s ...

Embodiment 2

[0076] For the analysis of the ultimate bearing capacity of the elbow described in Example 1, EPIA, whose calculation accuracy has been recognized in the field, was used to solve it, and ANSYS software was used to extract the number of iterations required by EPIA to solve the ultimate bearing capacity. The calculation results are shown in Table 5.

[0077] Table 5 Comparison of calculation accuracy and efficiency between EPIA and estimation methods

[0078] calculation method

[0079] It can be seen from Table 5 that the ultimate bearing capacity of the elbow calculated by the estimation method has good calculation accuracy, and the error with EPIA is only 6.21%. EPIA needs 433 iteration steps to solve the ultimate bearing capacity of the elbow, and the calculation efficiency is low. The method of the present invention only needs to pass through two linear elastic analysis, overcomes the complex loading process and multiple iterative analysis that EPIA needs to consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com