Electromechanical device equipment operation reliability degree analyzing method

A technology of electromechanical equipment and analysis methods, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., and can solve the problems of long and complex simulation running time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

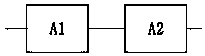

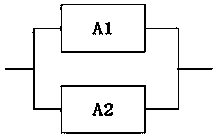

[0017] The present invention is used to describe the reliability relationship between the system and subsystems / sub-subsystems / equipment / components. The estimation and analysis of system reliability requires the reliability of sub-systems / sub-subsystems / equipment etc. Based on the reliability data, it is estimated and analyzed according to the connection relationship of the established reliability model.

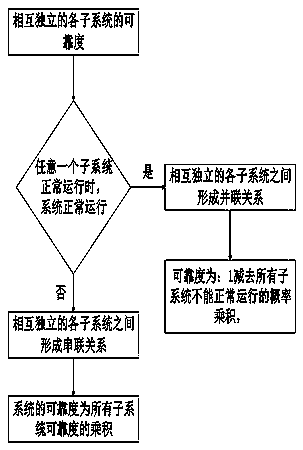

[0018] Therefore, when analyzing the reliability of the system, first determine the reliability of each independent subsystem, and determine what kind of connection relationship between the subsystems, and then use different reliability analysis algorithms according to different connection relationships, the system The necessary but not sufficient condition for normal operation is: at least one subsystem is in normal operation;

[0019] Preferably, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com