Textile dust collecting device for textile machine

A technology of machine spinning dust and collecting device, which is applied in the direction of combination device, dispersed particle separation, chemical instrument and method, etc., can solve the problems of increasing work intensity, large space occupied by textile dust expansion, and short residence time of textile dust. , to achieve the effect of ensuring the use effect, reducing labor intensity and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

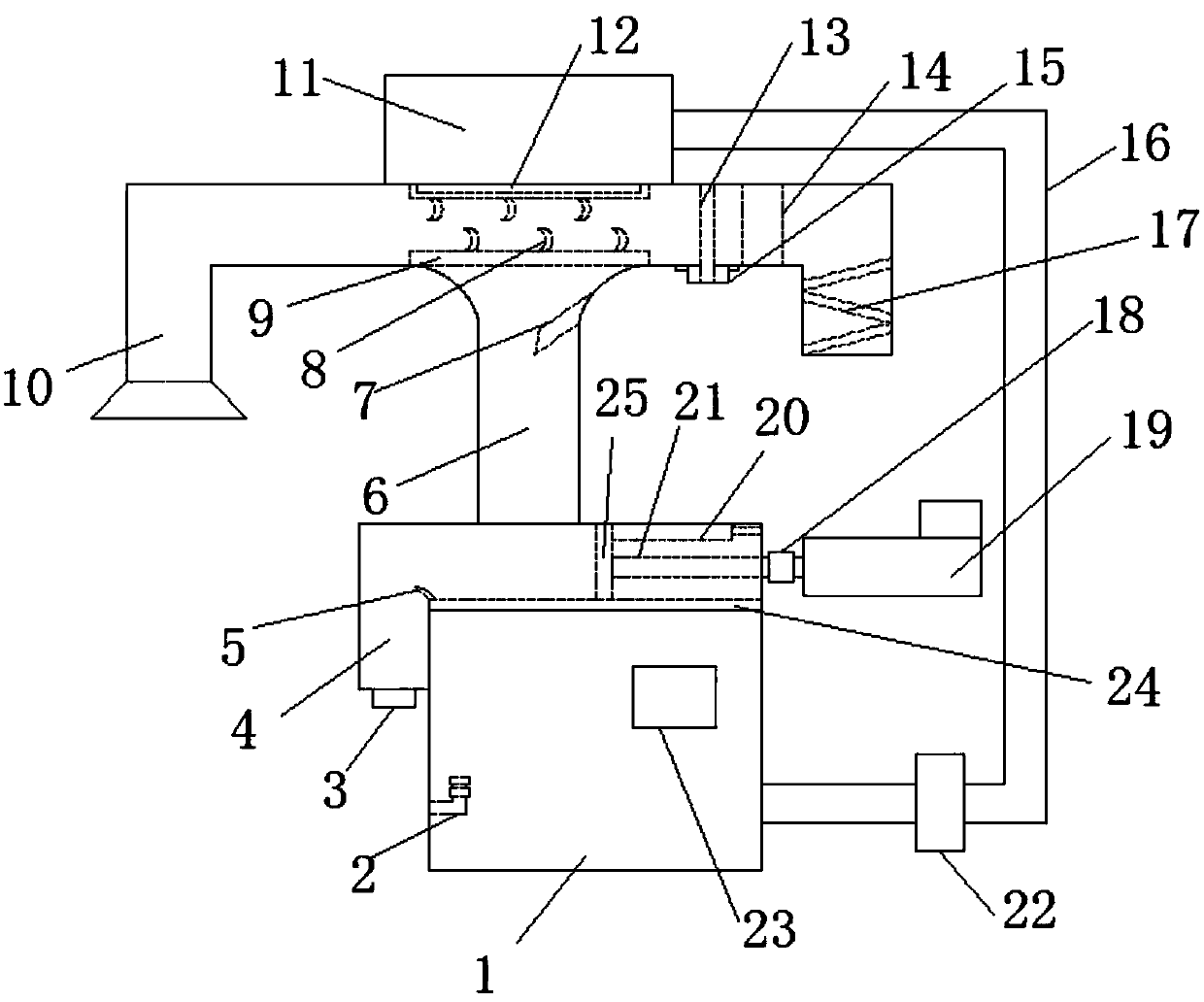

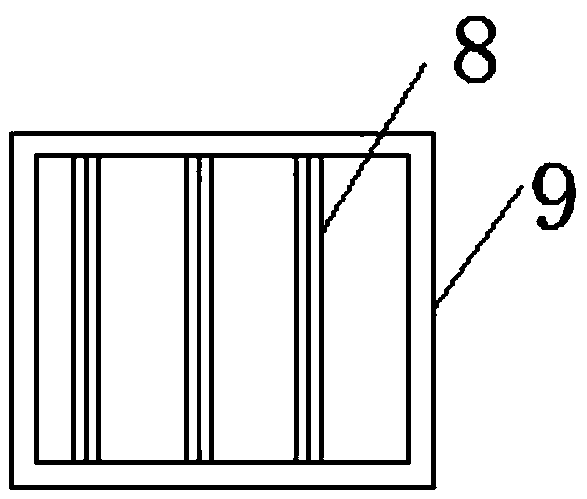

[0018] Such as Figure 1 to Figure 2 Shown, a kind of weaving machine weaving dust collecting device comprises collecting pipe 10, water tank one 11, water tank two 1, dust collecting pipe 6 and separating pipe 4, and one end of described dust collecting pipe 6 is connected with collecting pipe 10, The other end is connected with the separation pipe 4, the water tank one 11 is arranged above the collection pipe 10, the bottom of the water tank one 11 is provided with a shower head 12, and the water tank two 1 is arranged below the separation pipe 4, The water tank one 11 and the water tank two 1 are connected together by a water pipe 16, a water pump 22 is connected in series on the water pipe 16, an exhaust fan 14 is arranged in the collection pi...

Embodiment 2

[0021] Such as Figure 1 to Figure 2 Shown, a kind of weaving machine weaving dust collecting device, other steps in the present embodiment are identical with embodiment 1, difference is:

[0022] In this embodiment, the integrated pipe 6 is further provided with a sloping plate 7 . Effectively prevent the dust at the bottom of the dust collection pipe 6 from being sucked up by the wind.

[0023] In this embodiment, a liquid level switch 2 is also provided in the water tank 1, the position of the liquid level switch 2 corresponds to the position of the upper water pipe 16 of the water tank 1, and the liquid level switch 2 is connected to the controller 23 electrically connected together. When the water level in the water tank two 1 was lower than the liquid level switch 2, the liquid level switch 2 sent a signal to the controller 23, and the controller 23 controlled the water pump 22 to stop working, preventing the water pump 22 from air suction, causing the water pump 22 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com