An automatic and semi-automatic continuous-sample-injection reaction device and an operating method thereof

A technology of reaction device and sampling device, which is applied in the field of automatic and semi-automatic continuous sampling reaction devices, can solve the problems of inaccurate results, incomplete sample reaction, difficult stirring function, etc., to increase the number of samples injected, ensure High efficiency, time and cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

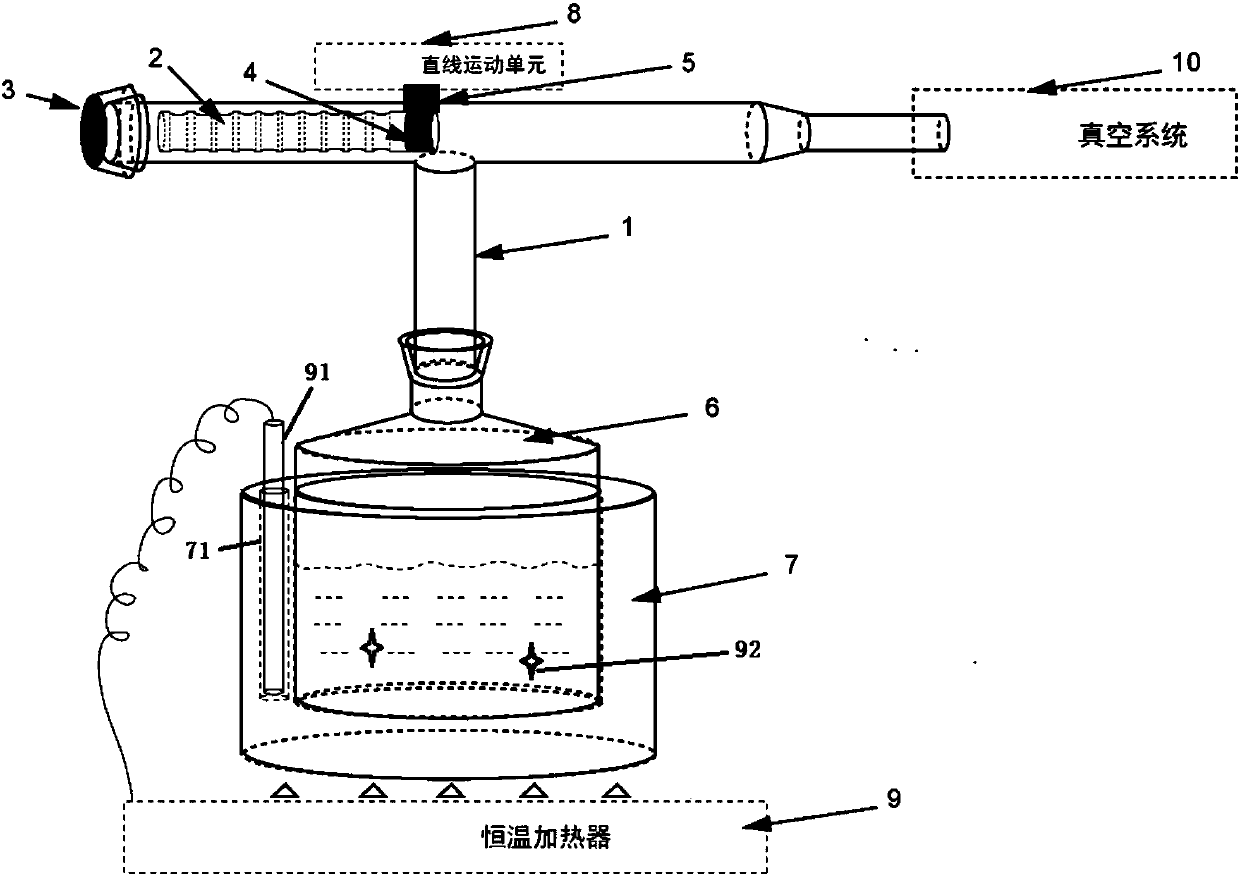

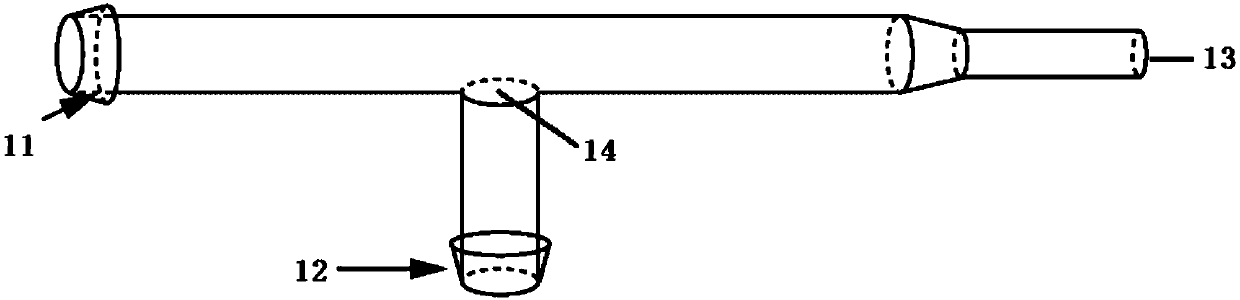

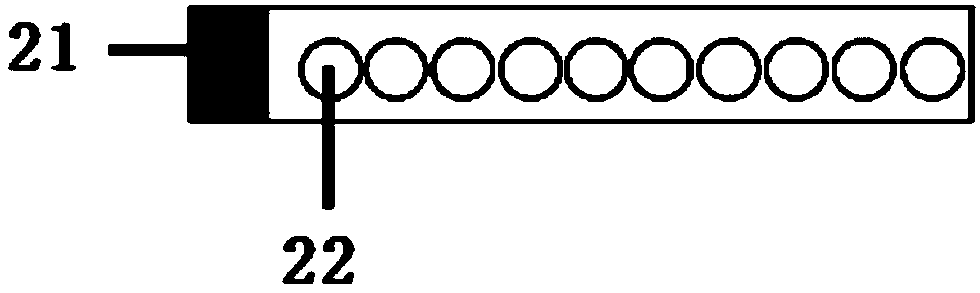

[0025] Such as figure 1 As shown, the present invention provides a novel automatic or semi-automatic continuous sampling reaction device under vacuum, the reaction device includes a sampling device main body 1 and a push rod 2 capable of realizing continuous sampling under vacuum, the described The push rod 2 is installed inside the main body 1 of the sampling device. The reaction device also includes a first magnet 4 and a second magnet 5 that can move synchronously under two relative environments (vacuum and non-vacuum) through the interaction between the magnets, and the first magnet 4 is installed on the pusher. On the rod 2, the synchronous movement of the push rod 2 is realized by moving the second magnet 5.

[0026] In order to make the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com