Method for measuring concentration of non-spherical particles of spouted bed

A non-spherical particle and measurement method technology, which is applied in the field of measurement of the concentration of non-spherical particles in a spouted bed, can solve the problems of affecting the experimental accuracy, shading, and the afterglow intensity of phosphorescent particles cannot be detected by a detector, so as to improve the accuracy and avoid the The effect of quadratic error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

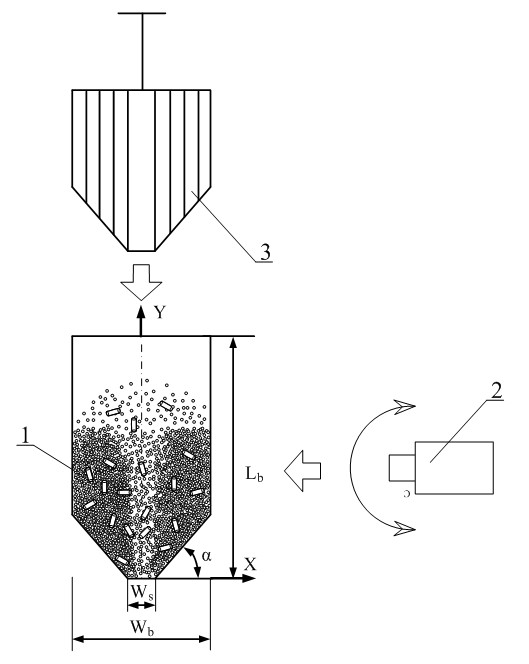

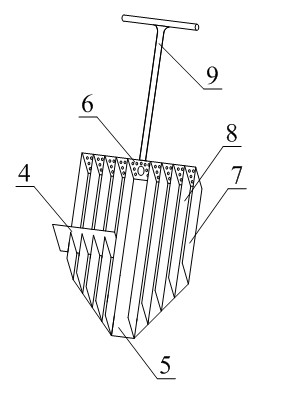

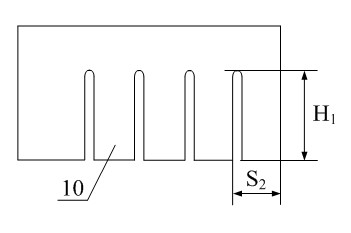

[0019] Refer to the following Figure 1~3 The implementation of the present invention will be described in detail. This embodiment is carried out on the premise of this technical solution, and the detailed implementation and operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

[0020] In this embodiment, a rectangular flat spouted bed is used, and the size of the bed body is: width 100 mm, depth 30 mm, height 250 mm. The nozzle size is: width 10mm, depth 30mm. The bed material is made of polystyrene particles with a particle size of 2.8 mm, and the non-spherical particles are cylindrical straw with a diameter of 2 mm and a height of 8 mm. At the beginning, the bed material and non-spherical particles are arranged in a completely separated manner. The bed material is placed on the lower layer, and the non-spherical particles are placed on the upper layer. The height of the bed material layer is 80mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com