Circuit breaker chassis clamping unit and circuit breaker chassis clamping tool

A technology for clamping tooling and circuit breakers, which is applied in the direction of manufacturing tools, metal processing equipment, used abrasive processing devices, etc., and can solve problems such as high labor intensity and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

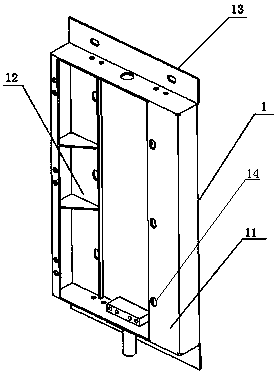

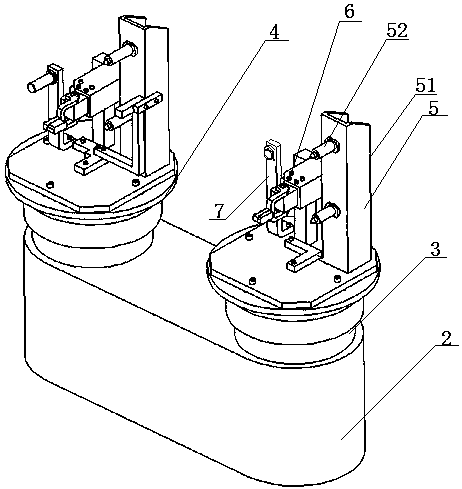

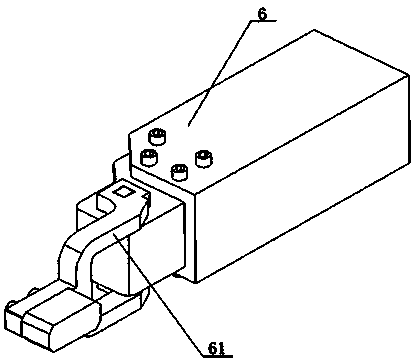

[0039] Specific embodiment 2 of the circuit breaker chassis clamping tool of the present invention, the support structure in the circuit breaker chassis clamping tool in this embodiment includes a support column, the support column is a columnar rod with a circular cross section. When the circuit breaker chassis clamping tool in this embodiment is used to clamp the circuit breaker chassis, the positioning pins on the circuit breaker chassis clamping tool pass through the connection holes on the circuit breaker chassis to realize the positioning of the circuit breaker chassis on the workbench. In order to prevent the circuit breaker chassis from shaking, the support column supports the circuit breaker chassis, and the cylinder in the pressing mechanism elongates to drive the pressing claws to rotate to achieve the purpose of clamping the circuit breaker chassis.

Embodiment 3

[0040] Specific embodiment 3 of the circuit breaker chassis clamping tool of the present invention, the circuit breaker chassis clamping tool in this embodiment includes a base and a workbench arranged on the base, one workbench, and the others are the same as in embodiment 1 ,No longer.

[0041] The structure of the clamping unit of the circuit breaker chassis of the present invention is the same as that of the clamping unit of the circuit breaker chassis in the clamping tooling of the circuit breaker chassis in the above-mentioned embodiments, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com