Bamboo tube precise processing equipment

A kind of equipment and bamboo tube technology, applied in the direction of mechanical equipment, sugarcane machining, etc., can solve problems such as low efficiency, achieve the effects of reducing labor costs, convenient and quick processing, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

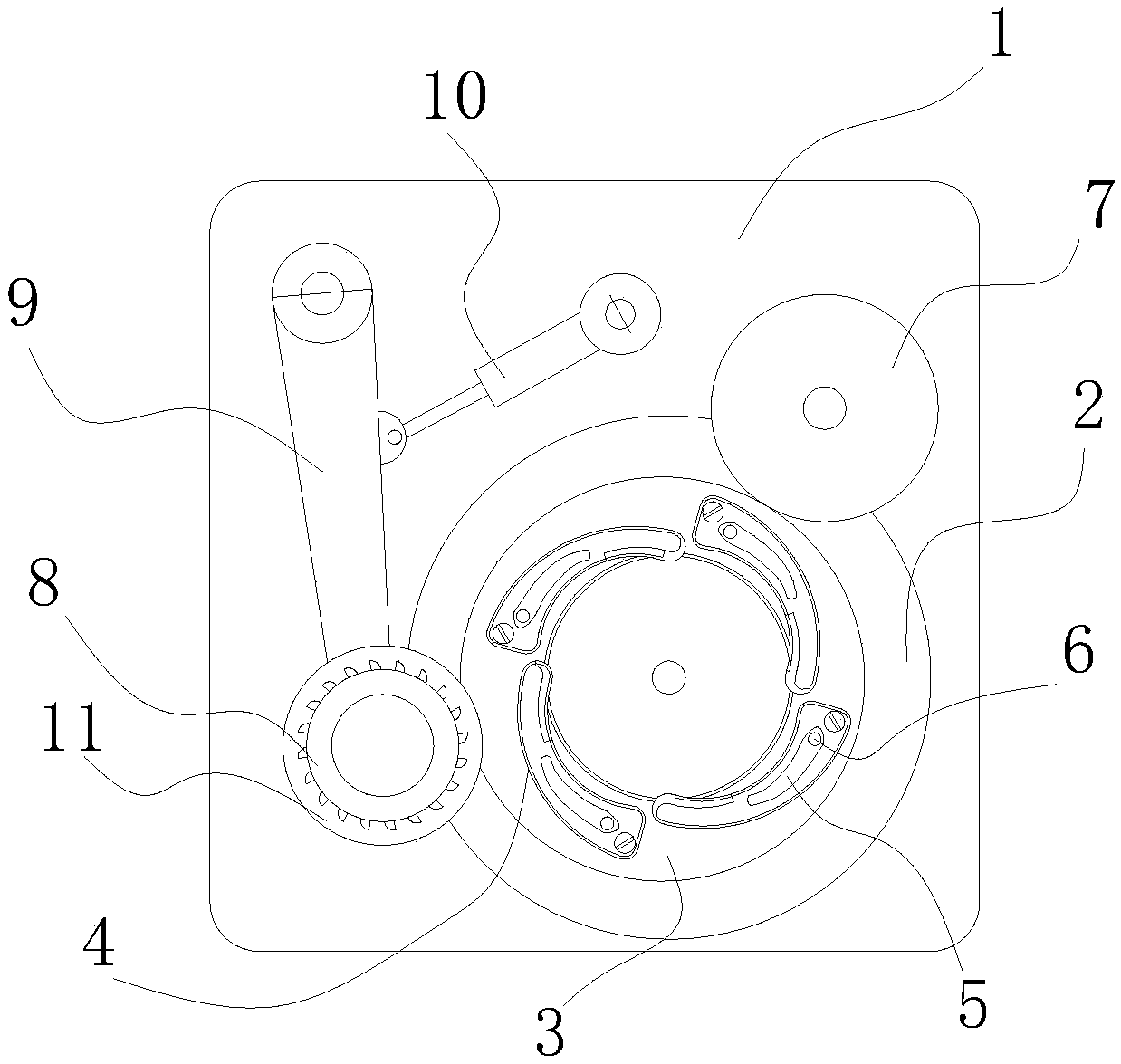

[0013] Example. A kind of bamboo tube finishing equipment, such as figure 1 As shown: including the main chassis 1, the main driving disk 2 is arranged on the top of the main driving disk 2, the driven disk 3 arranged concentrically is arranged on the top of the main driving disk 2, and more than three claws 4 are connected on the top of the driven disk 3 through the rotating pin , The jaw 4 is provided with an involute groove 5, and the involute groove 5 is provided with a limit pin 6 fixed with the main drive disc 2; the main chassis 1 is also provided with a cutting disc 8 (belt drive). The involute groove 5 is a chute whose angle with the claw 4 gradually increases from one side of the rotating pin to the other side. The main chassis 1 is also provided with a damping disc 7 close to the driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com