Cutting equipment for electromobile tire recovering

A cutting equipment, electric vehicle technology, applied in recycling technology, plastic recycling, metal processing, etc., can solve problems such as uneven cutting and laborious placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

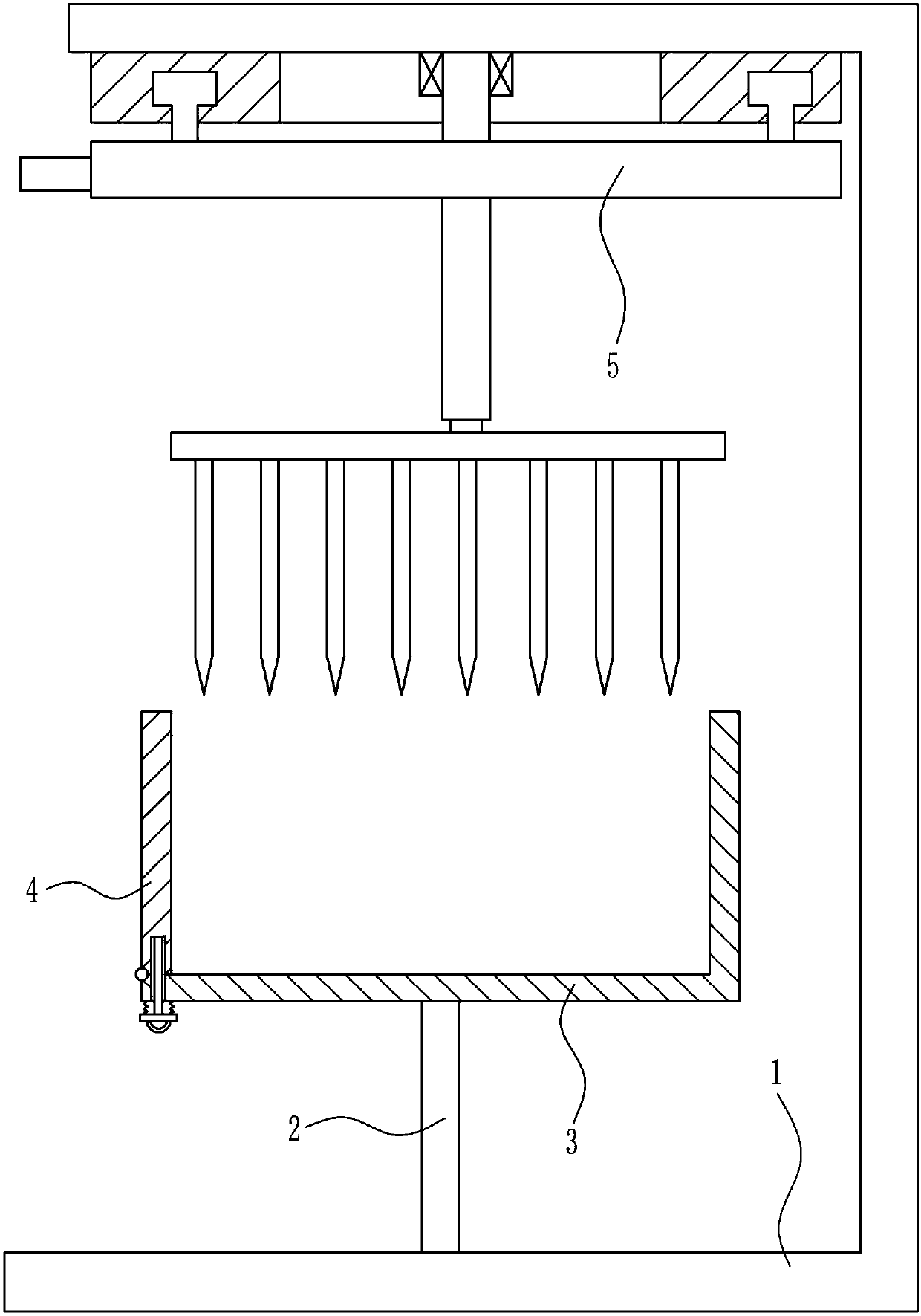

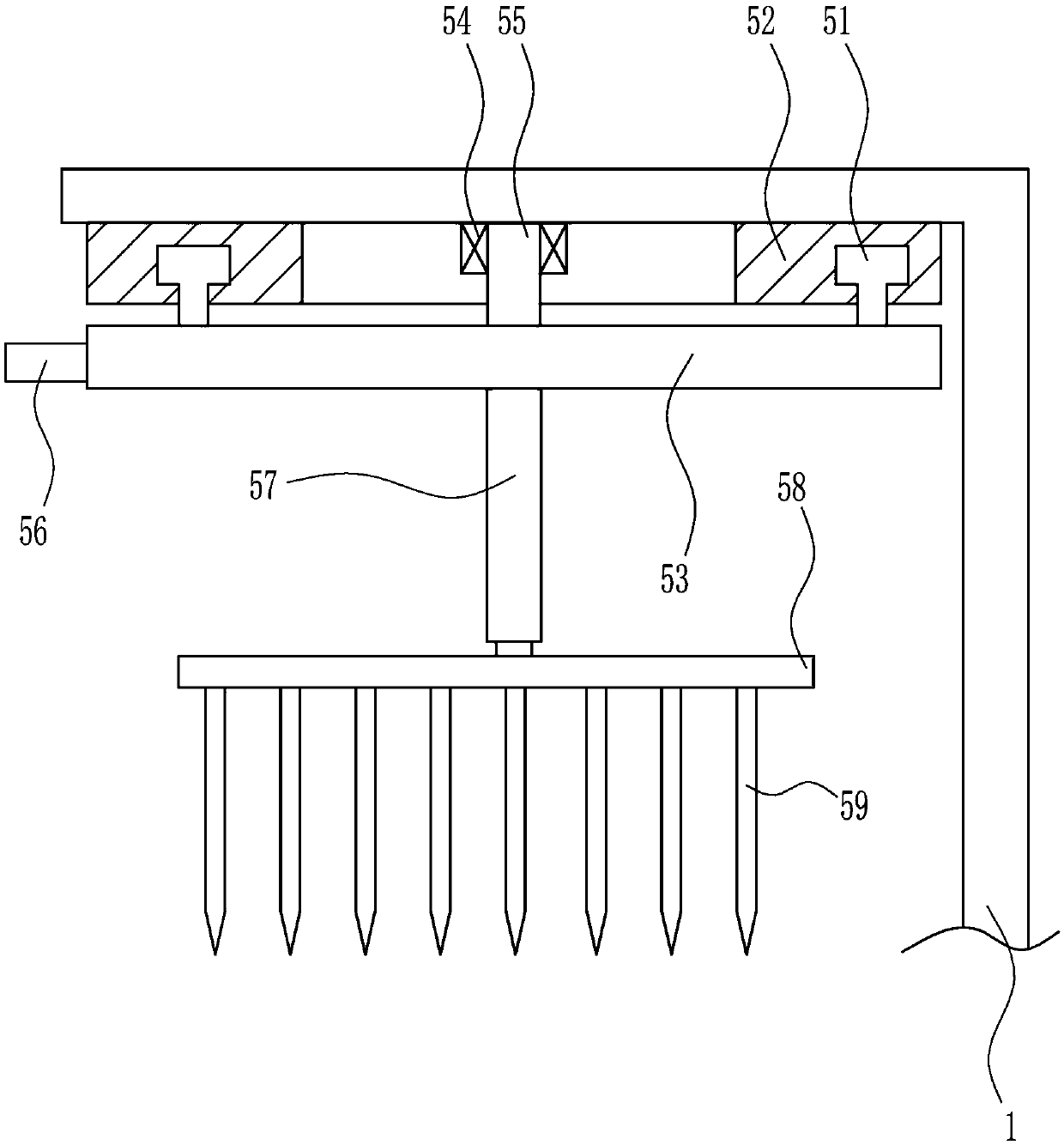

[0029] A cutting device for electric vehicle tire recycling, such as Figure 1-5 As shown, it includes a mounting frame 1, a pole 2, a frame body 3, a placement device 4 and a cutting device 5. The center of the bottom of the mounting frame 1 is provided with a pole 2, and the top of the pole 2 is connected to a frame body 3, and the frame body 3 The left part is provided with a placement device 4 , and the top of the installation frame 1 is provided with a cutting device 5 , which is above the frame body 3 .

Embodiment 2

[0031] A cutting device for electric vehicle tire recycling, such as Figure 1-5 As shown, it includes a mounting frame 1, a pole 2, a frame body 3, a placement device 4 and a cutting device 5. The center of the bottom of the mounting frame 1 is provided with a pole 2, and the top of the pole 2 is connected to a frame body 3, and the frame body 3 The left part is provided with a placement device 4 , and the top of the installation frame 1 is provided with a cutting device 5 , which is above the frame body 3 .

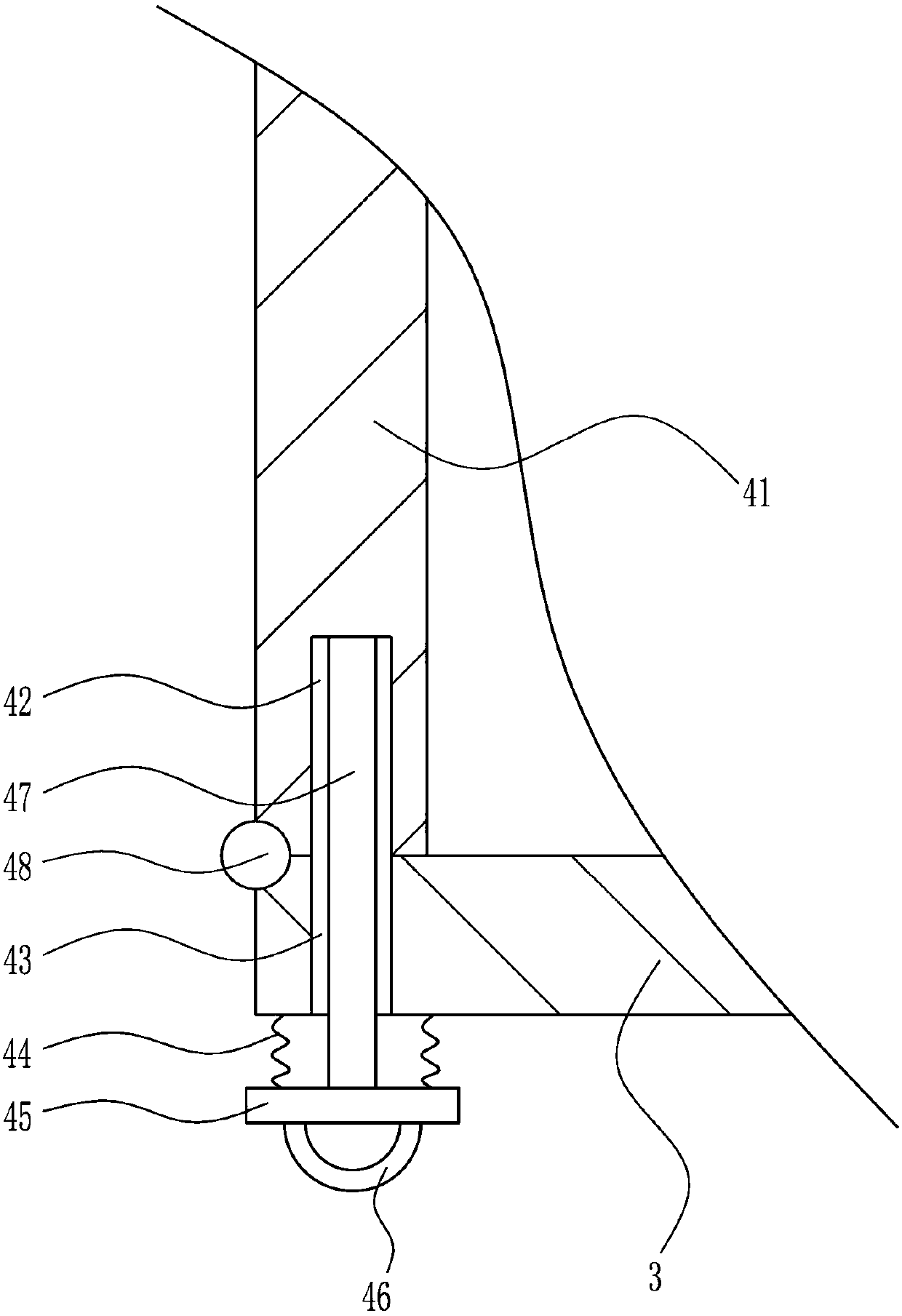

[0032]Placement device 4 comprises baffle plate 41, first spring 44, connecting plate 45, pull ring 46, inserting rod 47 and hinge 48, and frame body 3 inner bottom left side is connected with baffle plate 41 by hinge 48 rotatably, and baffle plate There is a groove 42 in the center of the bottom of 41, a through hole 43 is opened on the left side of the bottom of the frame body 3, and a first spring 44 is arranged symmetrically on the left and right sides of the bottom...

Embodiment 3

[0034] A cutting device for electric vehicle tire recycling, such as Figure 1-5 As shown, it includes a mounting frame 1, a pole 2, a frame body 3, a placement device 4 and a cutting device 5. The center of the bottom of the mounting frame 1 is provided with a pole 2, and the top of the pole 2 is connected to a frame body 3, and the frame body 3 The left part is provided with a placement device 4 , and the top of the installation frame 1 is provided with a cutting device 5 , which is above the frame body 3 .

[0035] Placement device 4 comprises baffle plate 41, first spring 44, connecting plate 45, pull ring 46, inserting rod 47 and hinge 48, and frame body 3 inner bottom left side is connected with baffle plate 41 by hinge 48 rotatably, and baffle plate There is a groove 42 in the center of the bottom of 41, a through hole 43 is opened on the left side of the bottom of the frame body 3, and a first spring 44 is arranged symmetrically on the left and right sides of the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com