Radial turbine of turbocharger and turbocharger

A technology of radial turbines and turbochargers, applied to gas turbine devices, machines/engines, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

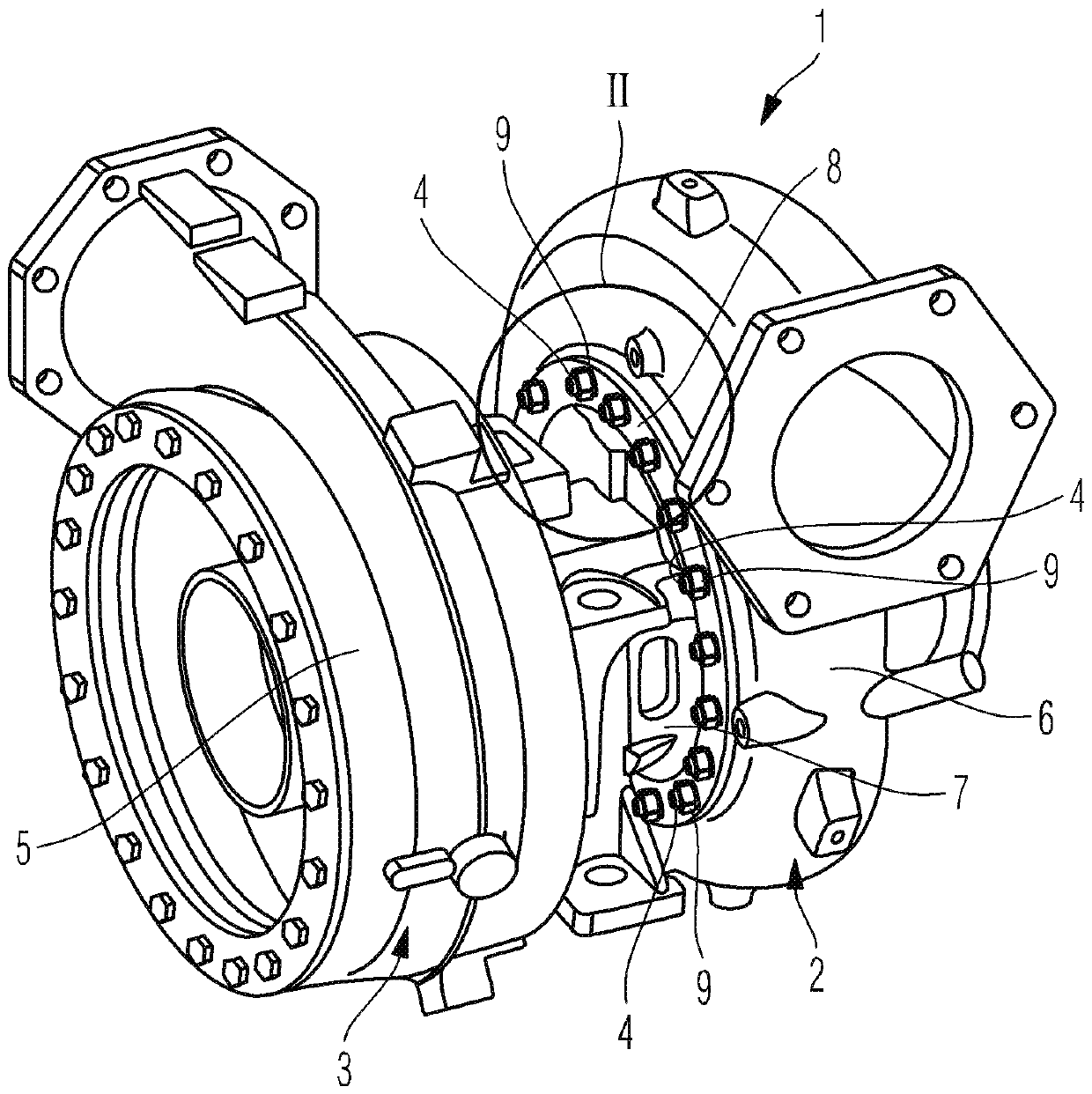

[0015] figure 1 A perspective view of a turbocharger 1 comprising a turbine 2 and a compressor 3 is shown. figure 1 The turbine 2 shown in is a radial turbine, and figure 1 The compressor 3 shown in is a radial compressor. In the turbine, the exhaust gas is expanded and the energy extracted in the process is used to compress the charge air in the compressor 3 .

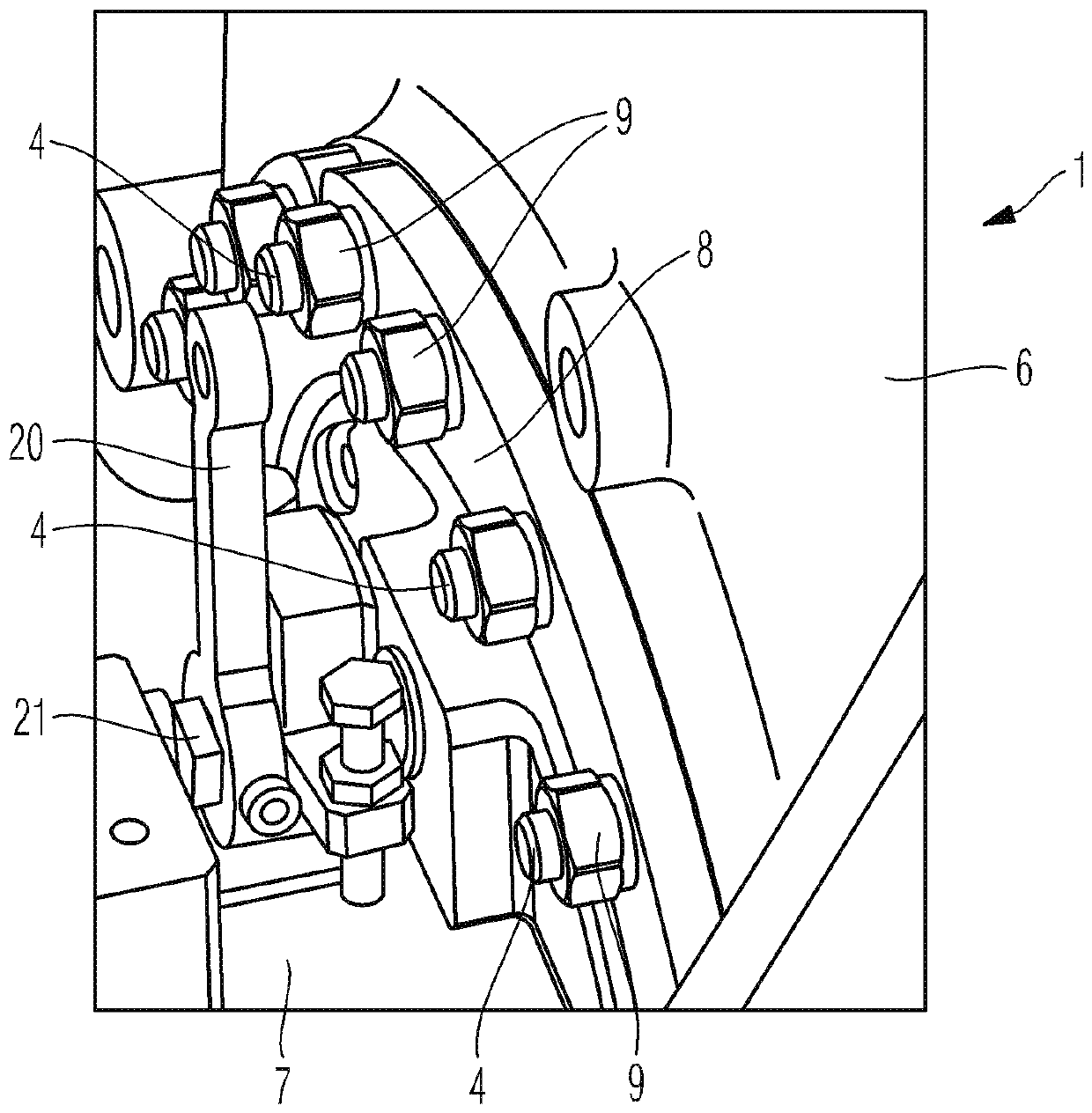

[0016] exist figure 1 , the turbine inflow housing 6 and the support housing 7 of the turbine 2 are shown, wherein the turbine inflow housing 6 and the support housing 7 are connected to each other via a fastening ring 8 which is also described as a clamping jaw . The fastening ring 8 is screwed to the turbine inflow casing 6 by means of several fastening screws 4 and fastening nuts 9 in such a way that, in the assembled state, the fastening ring 8 surrounds the bearing casing in sections 7 to engage the section 10 and thus mount the bearing housing 7 on the turbine inflow housing 6 . The compressor housing 5 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com