Universal double-acting gas floating frictionless cylinder

A non-friction cylinder, double-acting technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of the normal operation of the air-floating non-friction cylinder, the failure of the friction-free cylinder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

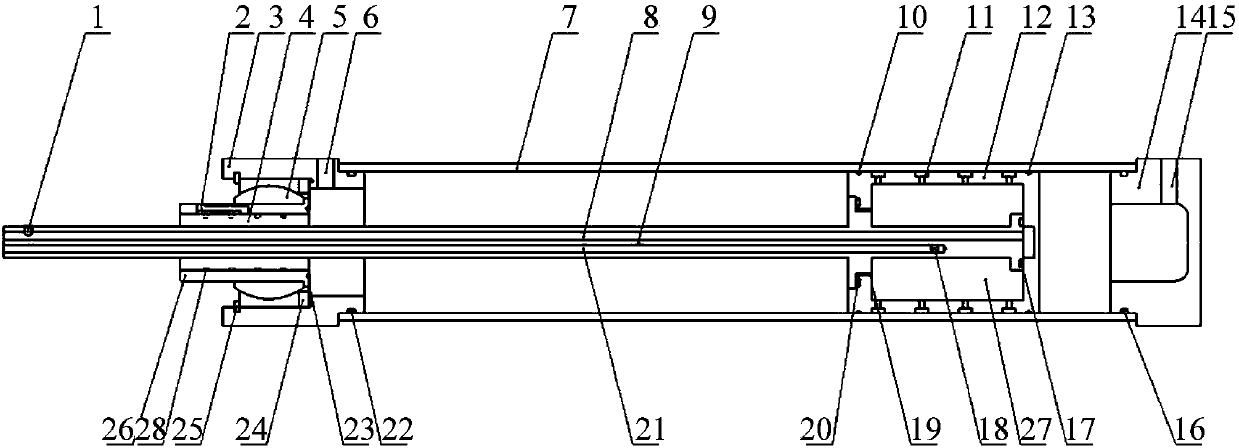

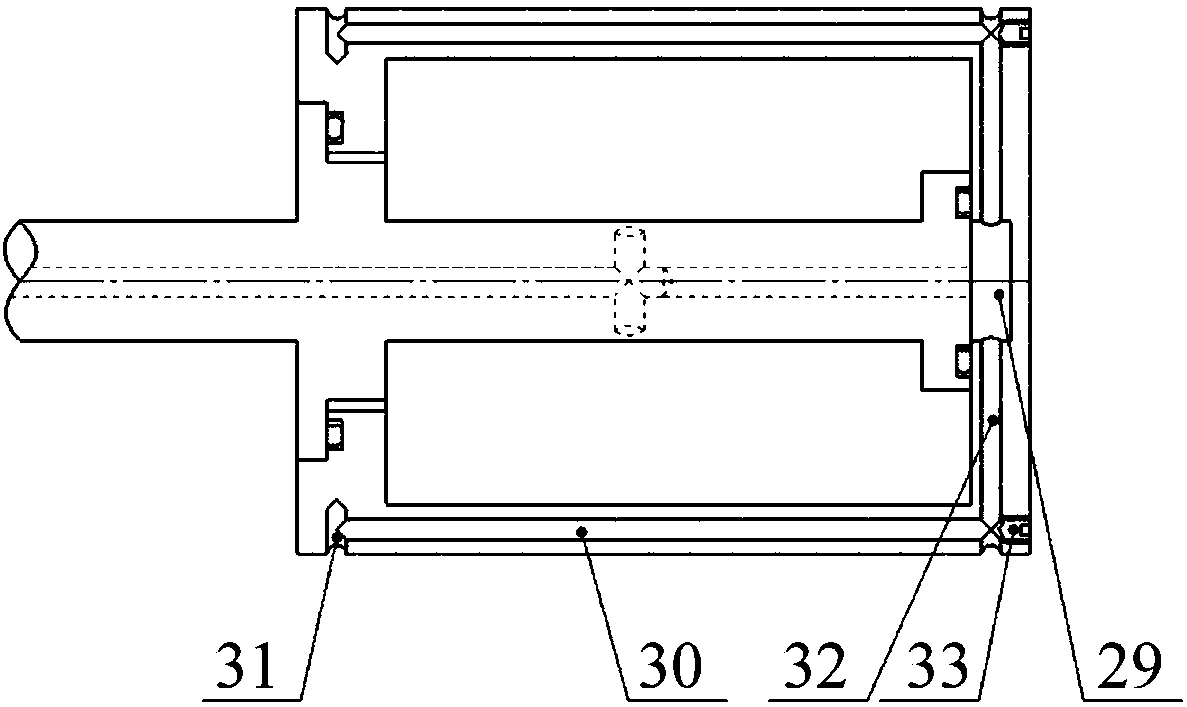

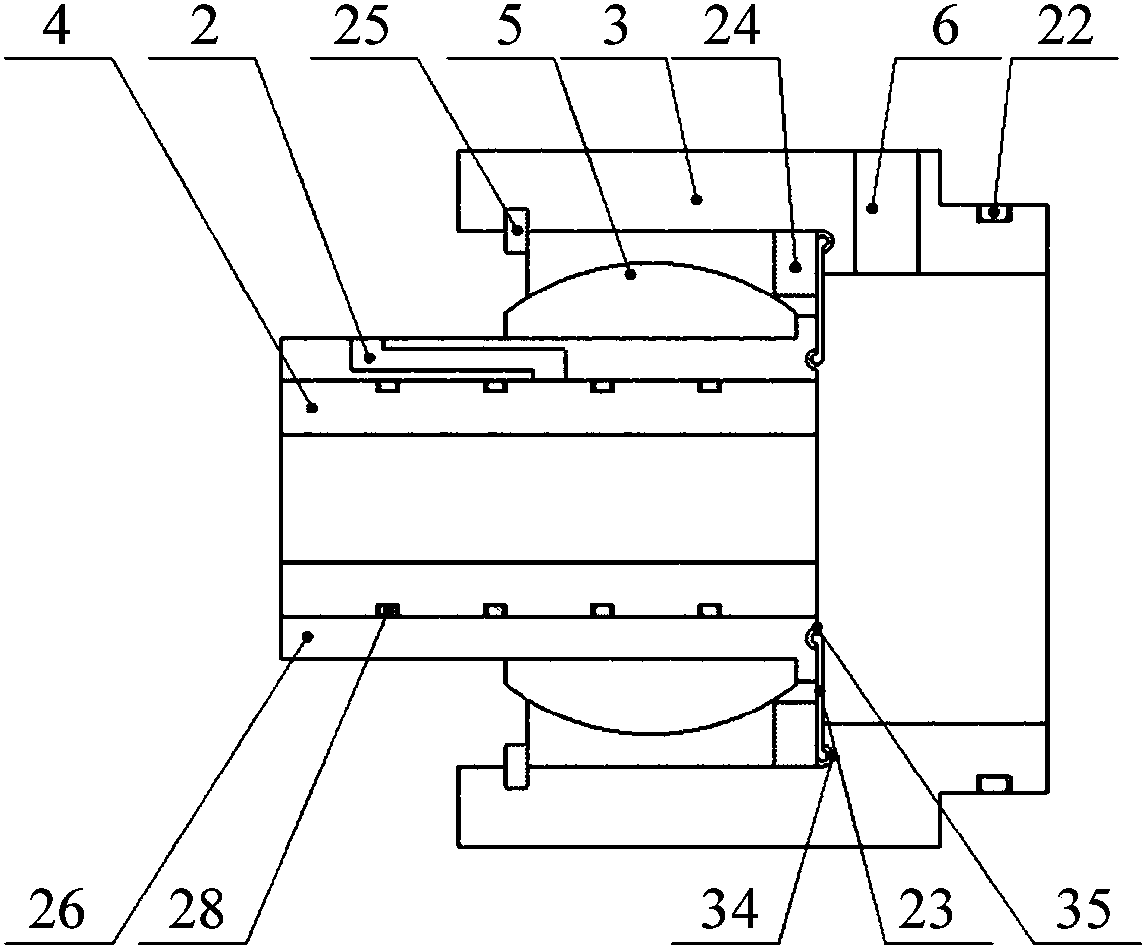

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0031] The invention adopts the principle of static pressure air flotation to design the air flotation piston of the frictionless cylinder, supplies air to the air flotation piston through external compressed air, and the compressed air flows to the outer cylindrical surface of the piston and the inner wall surface of the cylinder barrel through the throttle holes uniformly distributed in the circumferential direction of the piston. The gap between jets high-pressure air flow to form a film bearing piston. Likewise, the piston rod is supported by an air film formed by the airflow from the externally supplied porous air bearing. In this way, the moving part formed by the threaded connection of the piston and the piston rod can realize non-contact with the stationary part f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com