Color temperature-adjustable LED light source and manufacturing method thereof

A technology of LED light source and manufacturing method, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of high light intensity, uneven two-color mixed light, weak peripheral light intensity, etc., and achieve the effect of uniformly mixed white light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

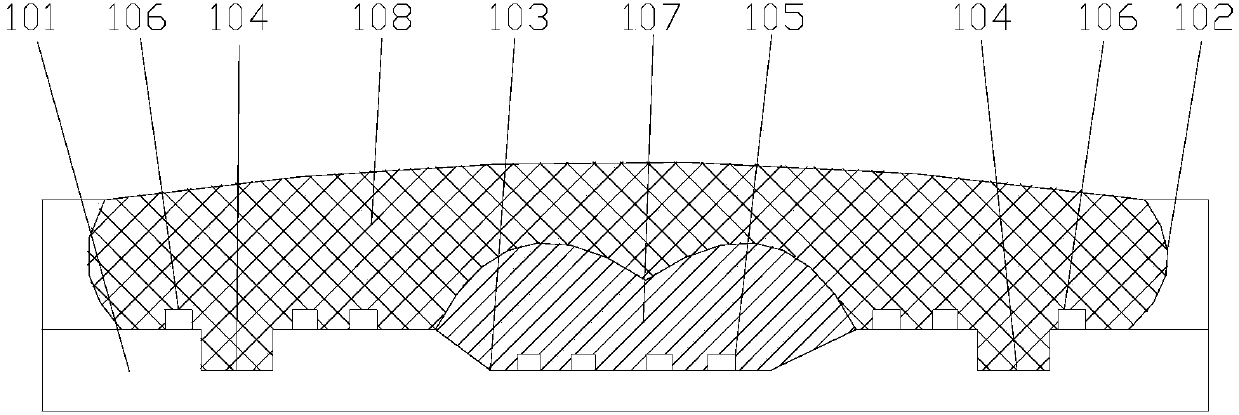

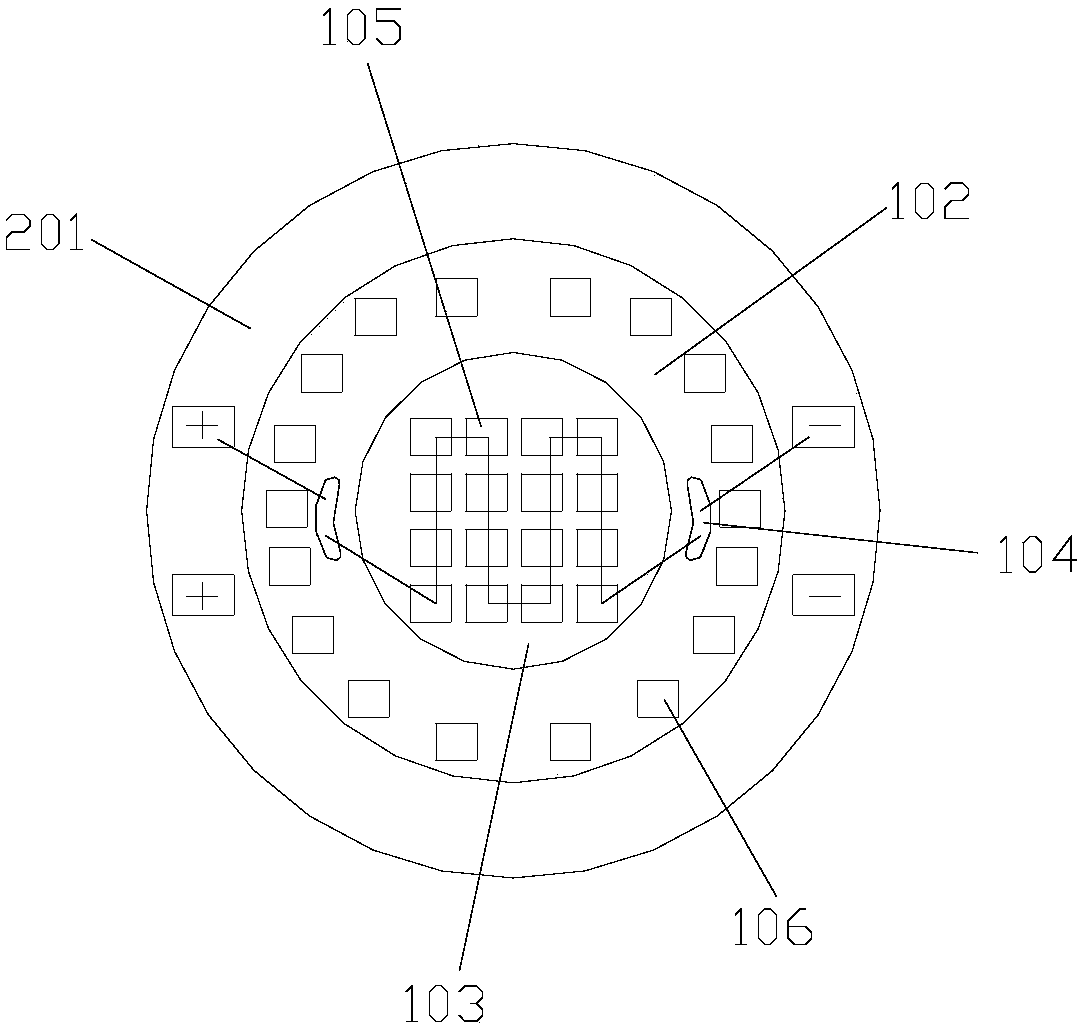

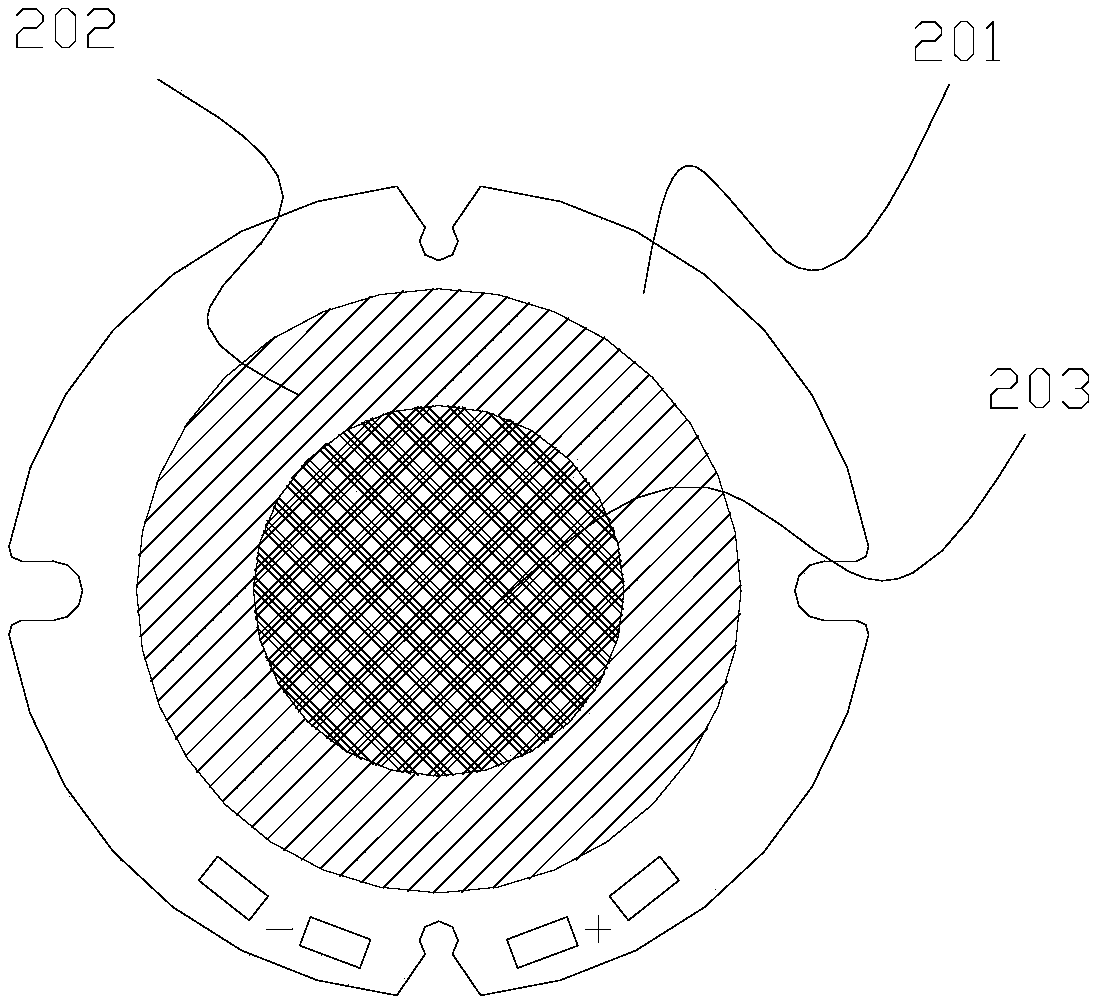

[0043] Such as figure 1 As shown, this embodiment discloses an LED light source with adjustable color temperature and uniform light mixing, including a first LED chip group 104, a second LED chip group 105, and an LED substrate. An integrally formed plastic reflector is arranged on the LED substrate, and a circular reflective cavity 102 is provided in the middle of the reflector. The circular reflective cavity 102 runs through the reflector, and the side wall of the circular reflective cavity 102 is arc-like. The center of the top surface of the thermally conductive substrate within the range corresponding to the circular reflection cavity is provided with a rounded truncated groove, and the top surface of the thermally conductive substrate is strip-shaped in the rounded truncated groove and on the periphery of the rounded truncated groove.

[0044] The material of the reflector is PPA, PCT, EMC, SMC and other high heat-resistant engineering plastic materials. At the same time...

Embodiment 2

[0055] The invention provides a method for manufacturing an LED light source with adjustable color temperature, comprising the following steps:

[0056] S1. Fabricate a reflector with an open circular emitting cavity on the heat-conducting substrate by injection molding or molding.

[0057] S2. Making a rounded frustum-shaped groove in the middle of the bottom surface of the emitting chamber by stamping or etching.

[0058] S3. Fix the first LED chipset in the rounded truncated groove, and fix the second LED chipset on the bottom surface of the reflective cavity outside the rounded truncated groove.

[0059] S4. Fill the first groove with fluorescent colloid Y1, a fluorescent colloid Y1 covering the first LED chipset; fill the reflective cavity with fluorescent colloid Y2, and the second fluorescent colloid Y2 covering the first fluorescent colloid.

[0060] S5. High temperature curing fluorescent colloid Y1 and fluorescent colloid Y2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com