Automatic threading machine with high performance and used for cable burying

A high-performance, automatic threading technology, applied in the field of threading machines, can solve the problems of unable to realize the automatic release and retraction of lead wires, poor working stability, etc., and achieve the effect of improving clamping effect, ensuring stability and ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

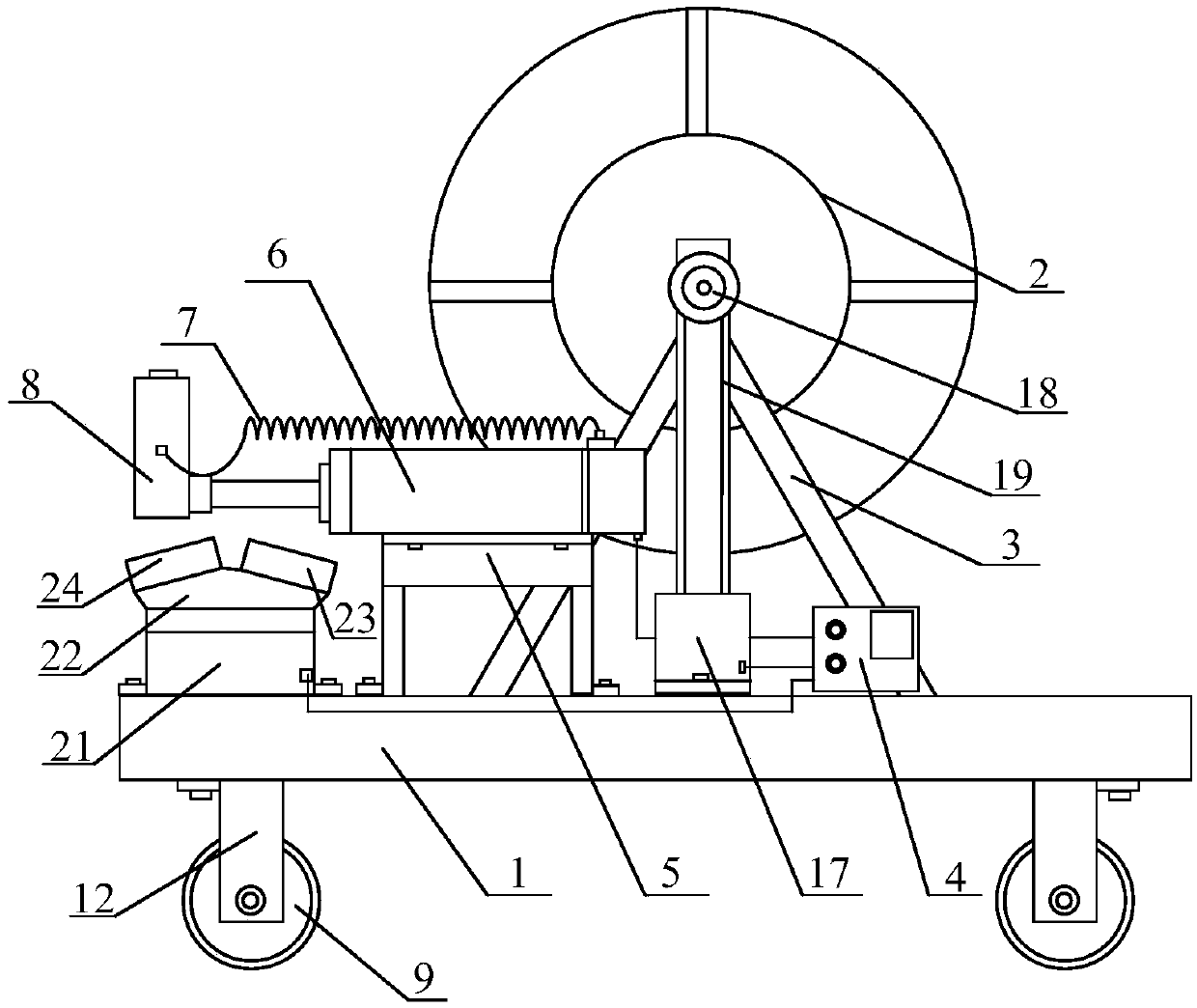

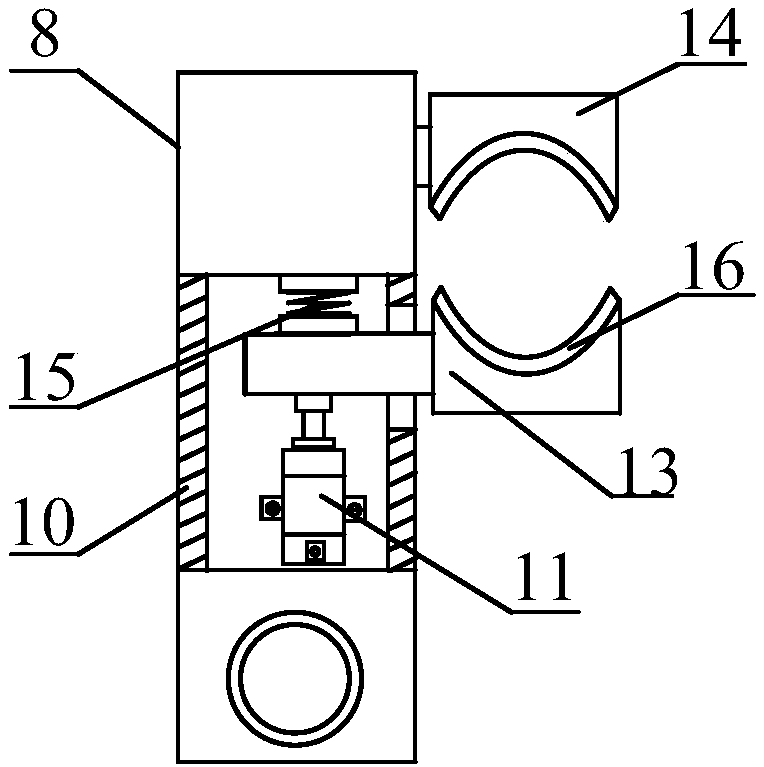

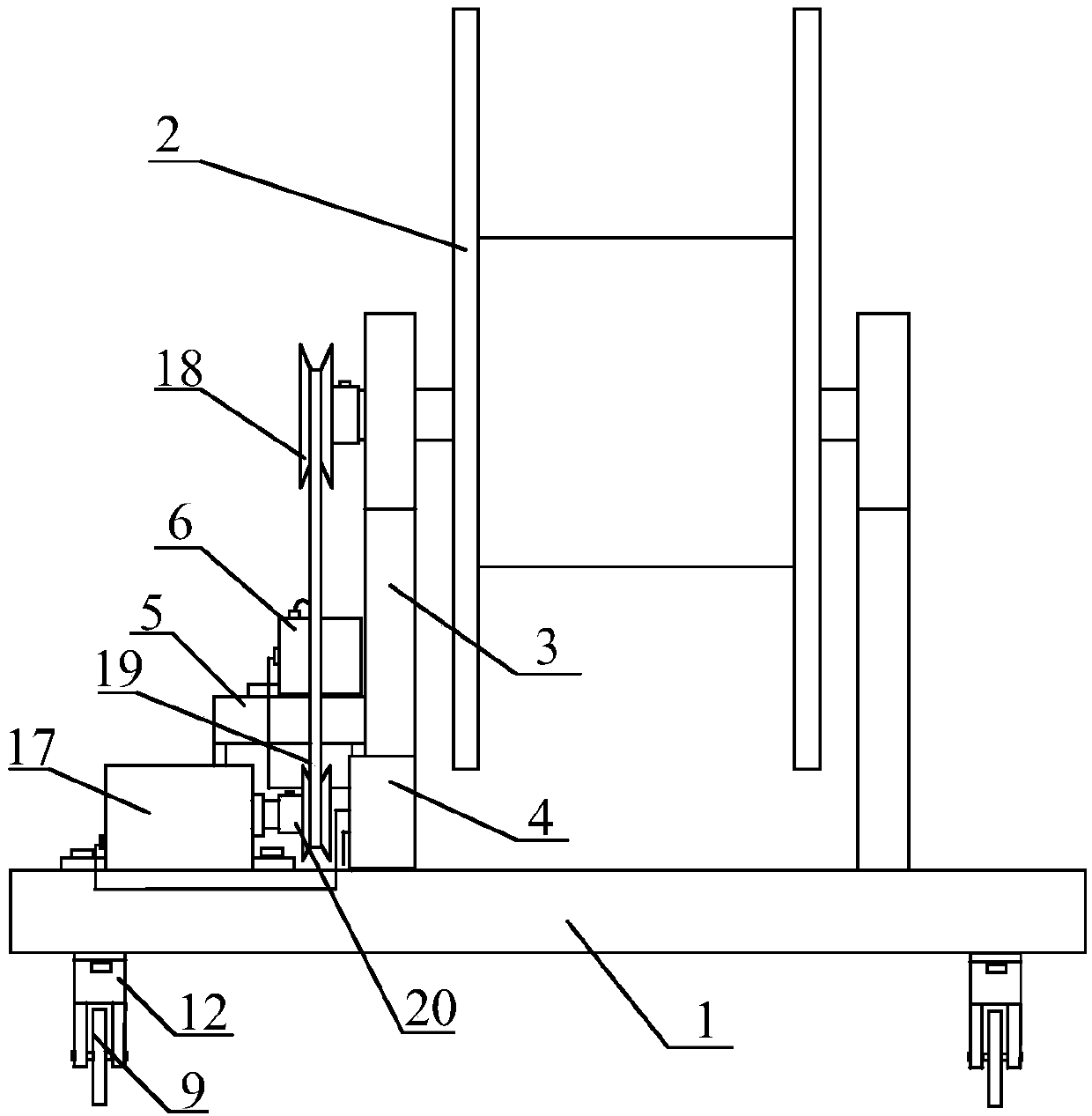

[0025] Such as Figure 1~3 As shown, the present invention discloses a high-performance automatic threading machine for cable embedding, which includes a base 1, a reel 2, a heat sink, a stranding device, a cylinder 6, a clamp 8, and a controller 4.

[0026] In implementation, the base 1 serves as the support and carrier of the entire stringing machine. In order to facilitate the movement of the automatic stringing machine by the operator, the base 1 is equipped with a roller 9 on the bottom surface, and in order to keep the base 1 balanced, There are four rollers 9 in this embodiment, and the four rollers 9 are respectively installed on the four corners of the bottom surface of the base 1 through the roller frame 12. The reel 2 is installed on the base 1 through a bracket 3. The reel 2 is used to place the leads, and the shaft of the reel 2 is movably mounted on the bracket 3. The bracket 3 can be set up in specific production. It can be set to two. In this embodiment, in order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com