Workpiece detection jig

A workpiece detection and jig technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of inconvenient assembly and disassembly, time-consuming and other problems, achieve the effect of convenient assembly and disassembly, and improve assembly and disassembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

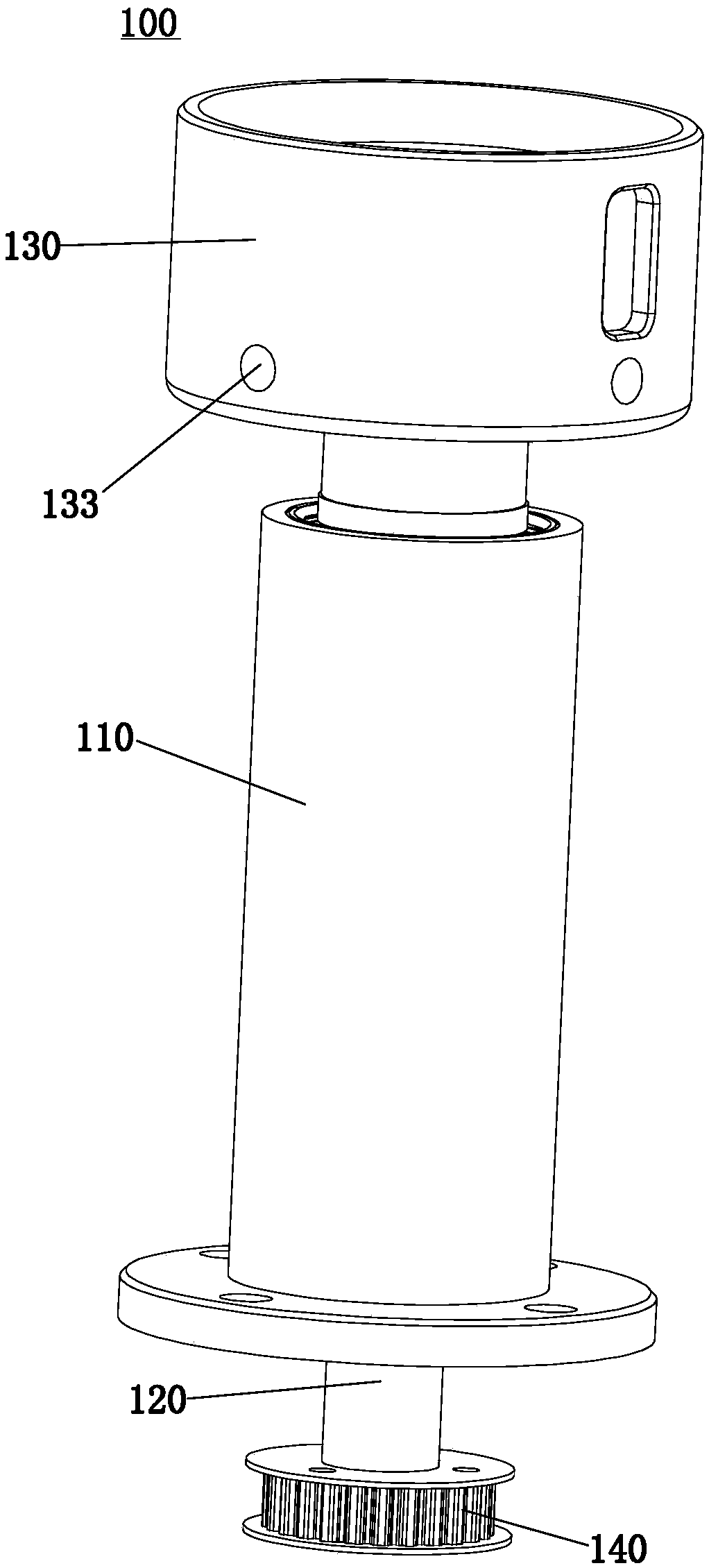

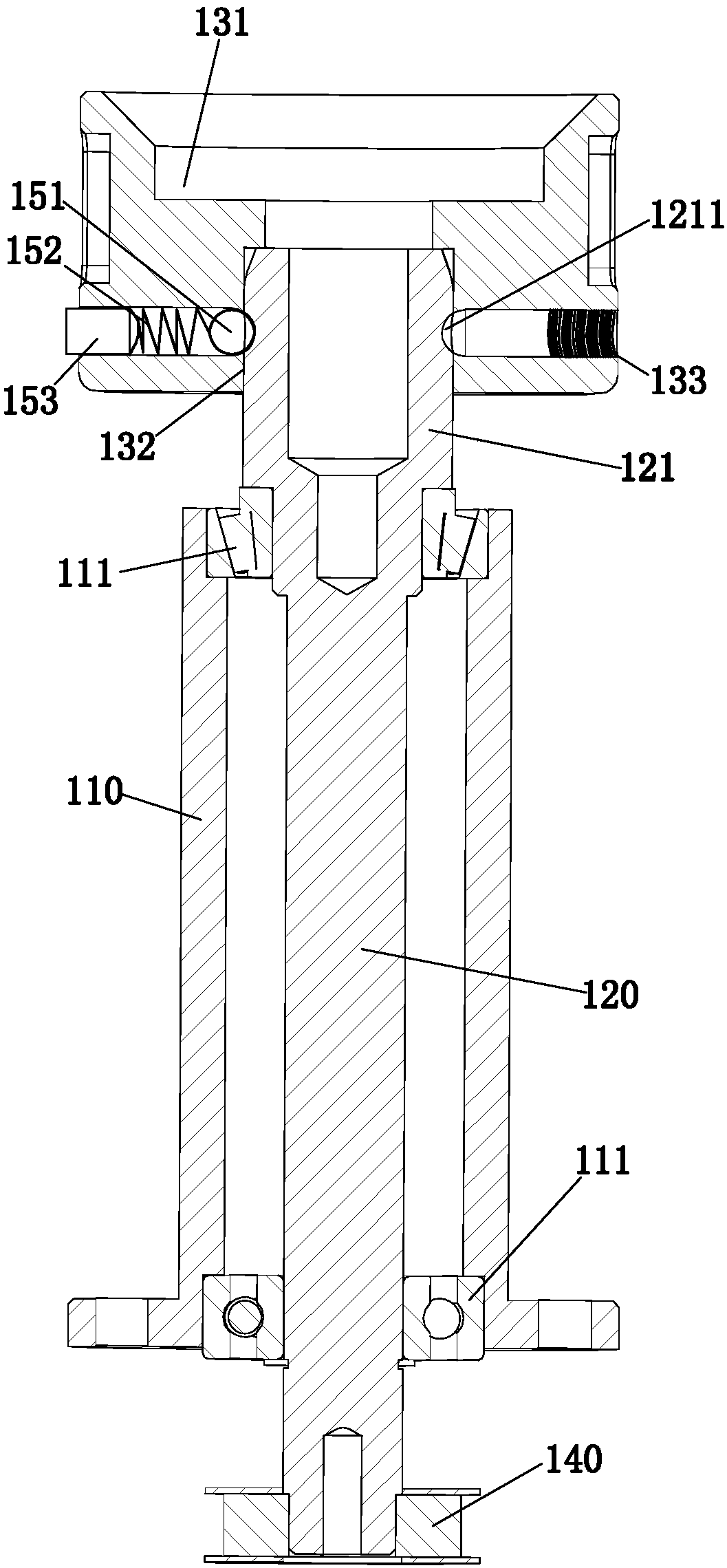

[0010] refer to figure 1 and figure 2 , The workpiece detection jig 100 of the present invention includes a flange bushing 110, a rotating shaft 120, a glue-coated rotating seat 130, a transmission wheel 140 and at least three sets of replacement and fixing components.

[0011] The replacement and fixing assembly includes a snap ball 151 , a spring 152 and a screw 153 .

[0012] The rotating shaft 120 is rotatably installed in the flange bushing 110, specifically, the upper end and the lower end of the flange bushing 110 are embedded with fixed bearings 111 respectively, and the upper and lower parts of the rotating shaft 120 are fixedly inserted in the corresponding to the bearing 111. The lower end of the rotating shaft 120 protrudes from the flange sleeve 110 and is fixedly connected with the transmission wheel 140 . The upper end of the rotating shaft 120 is provided with a connecting head 121 protruding from the flange sleeve 110 . The middle part of the top of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com