Push type speed change mechanism

A speed change mechanism and push-type technology, which is applied in the direction of mechanical equipment, transmission devices, friction transmission devices, etc., can solve the problems of complex manufacturing, easy failure of the transmission mechanism, and inability to obtain high-torque transmission, so as to avoid the problem of high manufacturing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

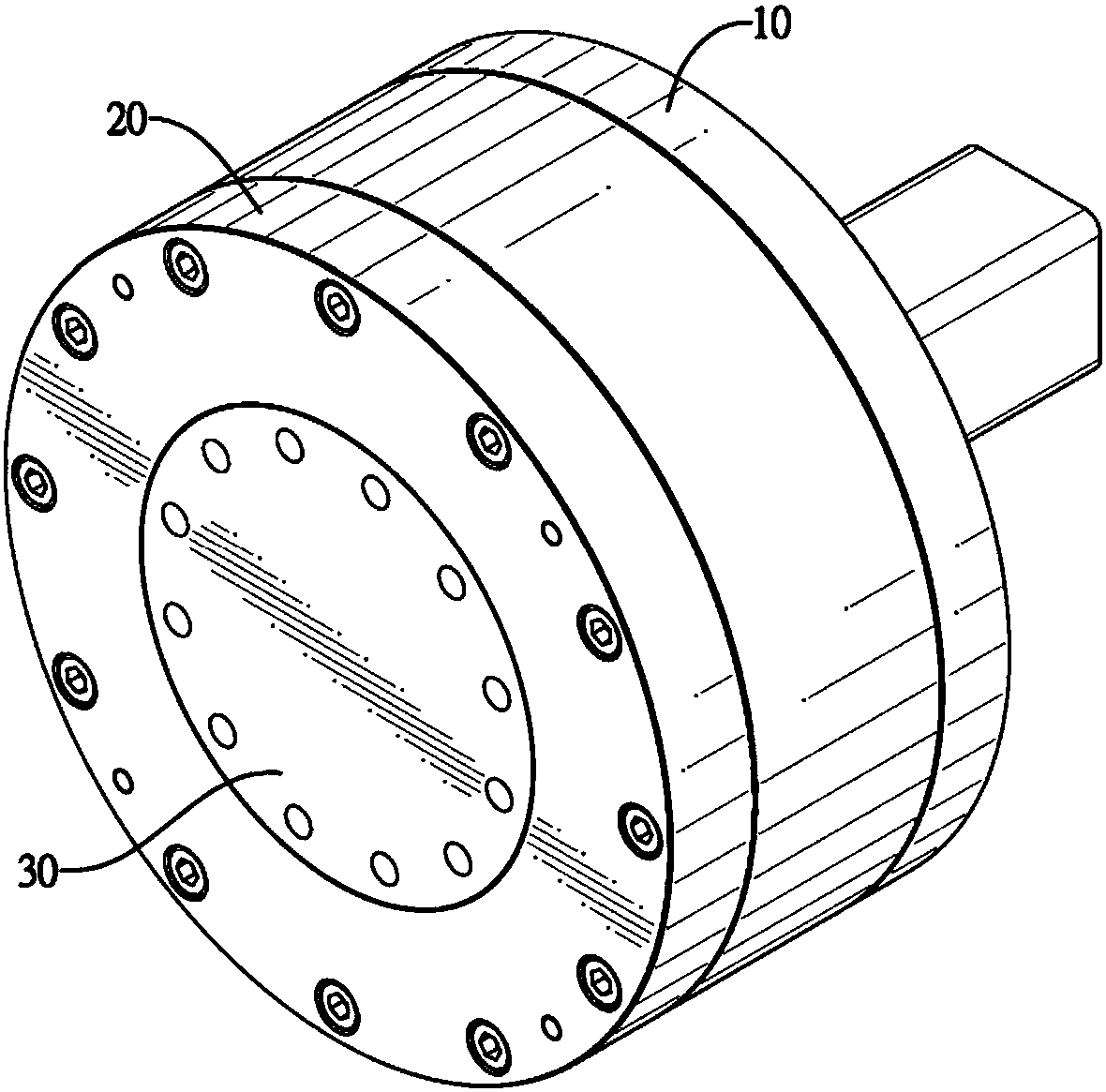

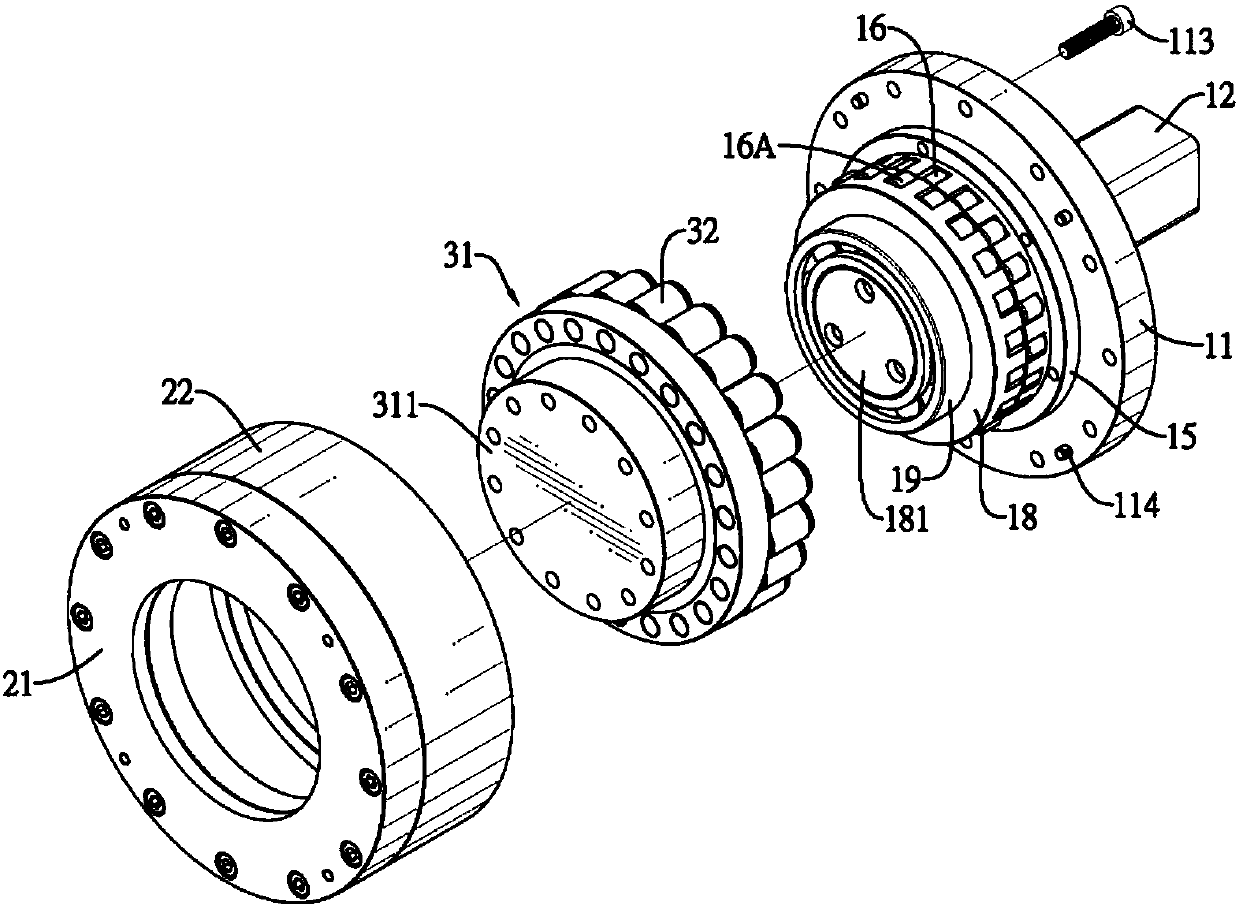

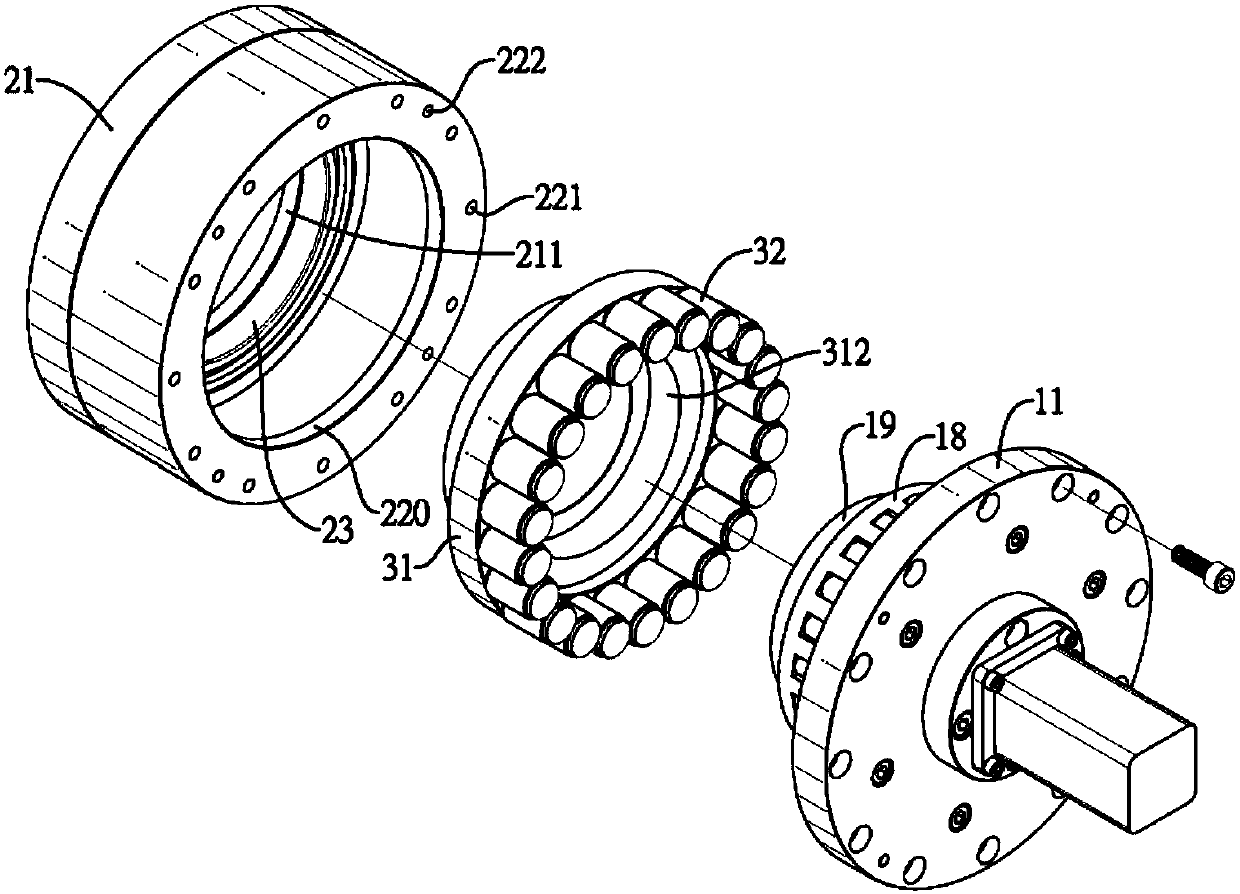

[0031] Please refer to figure 1 As shown, the first embodiment of the push-type transmission mechanism of the present invention has a power transmission unit 10 , a cover 20 and an output member 30 .

[0032] Please refer to figure 2 , 4 And shown in 6, this power transmission unit 10 has a base 11, a motor 12, a driving gear set 13, a base bearing 14, a first fixed disc 15, a plurality of transmission rolling elements 16, 16A, a drive Part 17 and a second fixed plate 18 and an output bearing 19.

[0033] The base 10 has an accommodating slot 110 , a setting platform 111 , at least one assembly column 112 , a plurality of coupling components 113 and a plurality of positioning components 114 .

[0034] The accommodating groove 110 is recessed and formed on one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com