Disassembly and assembly tool for floating valve core and float valve using same

A floating valve and spool technology, applied in the manufacture of tools, hand-held tools, casings, etc., can solve the problem of increasing downhole tools and well control risks, unfavorable internal threads of float valve joints, and affecting the service life of float valve spools, etc. problem, to achieve the effect of improving the combination and dismantling efficiency, simple structure and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

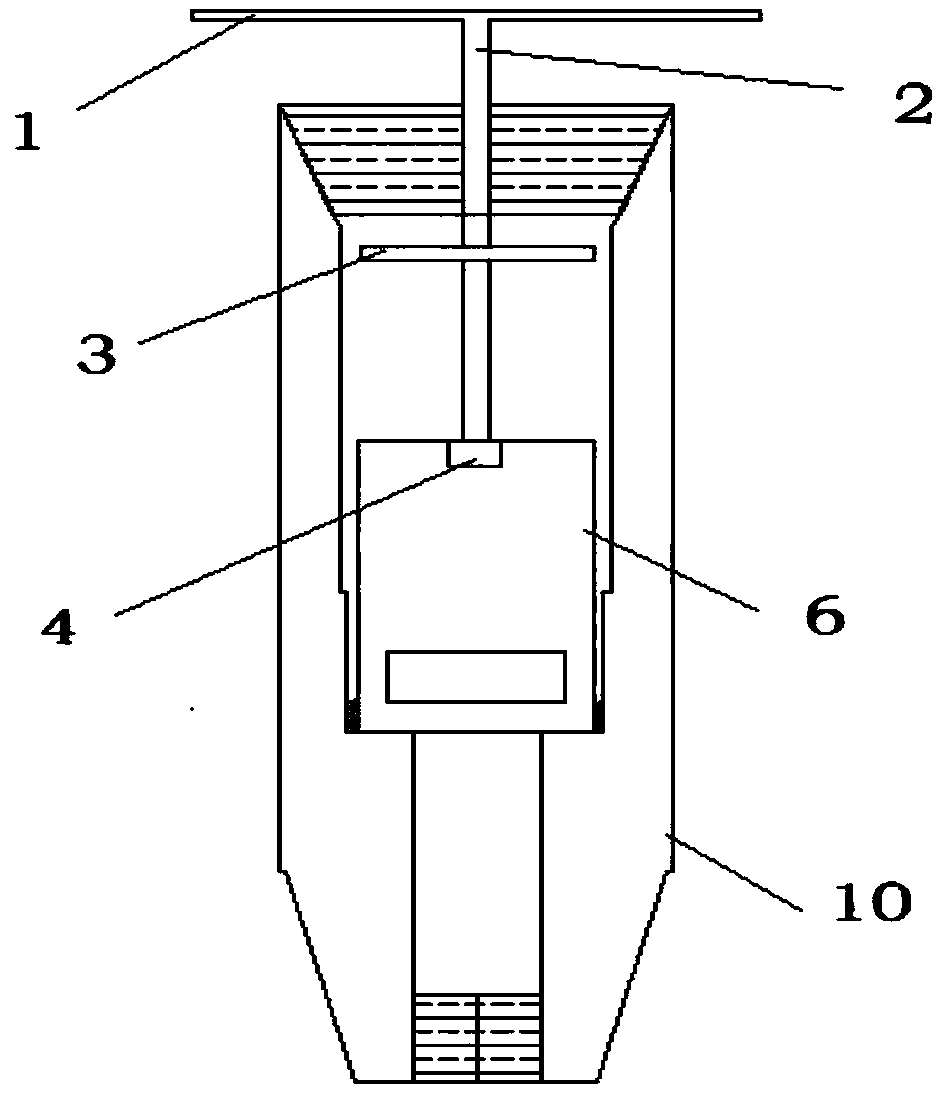

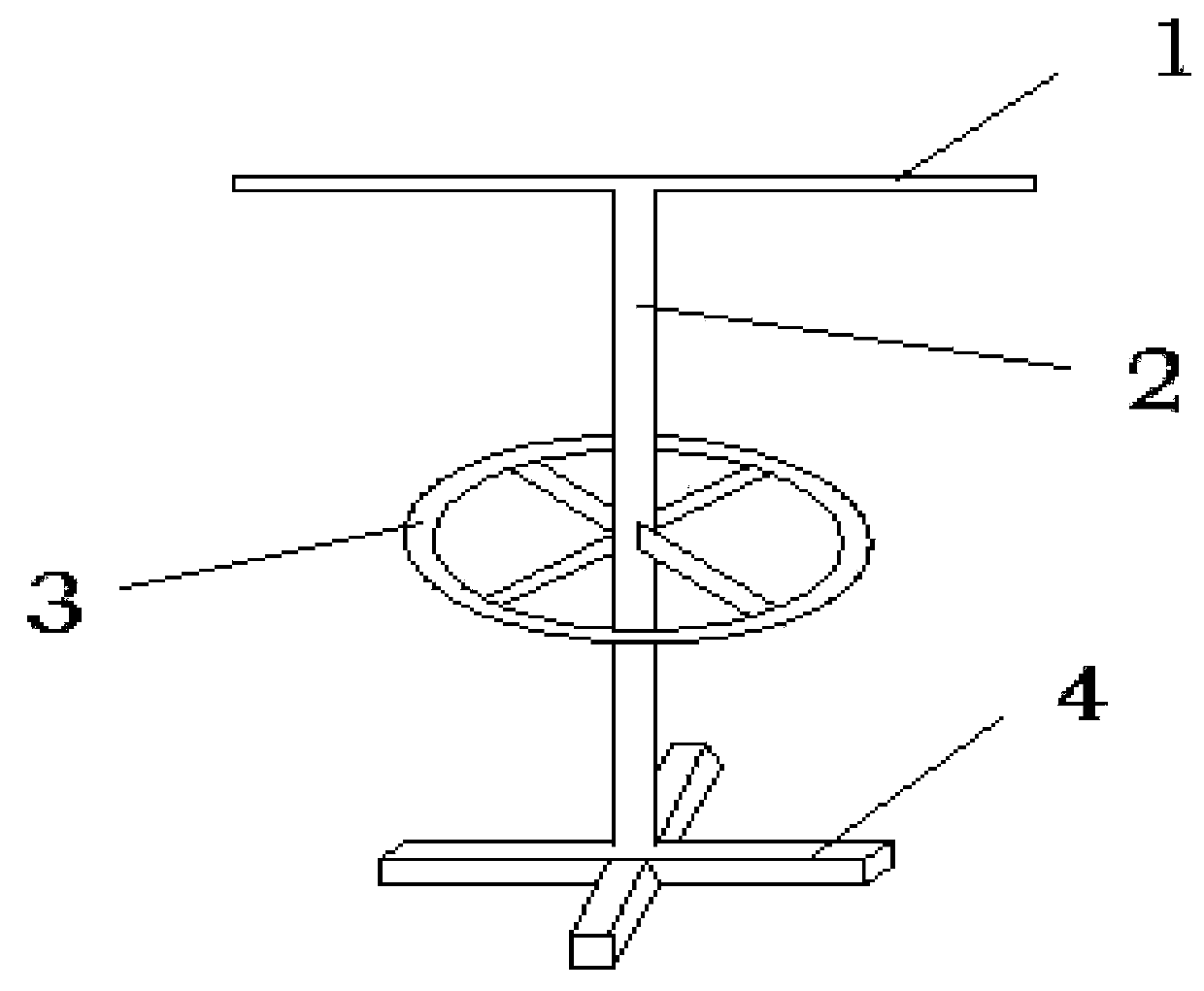

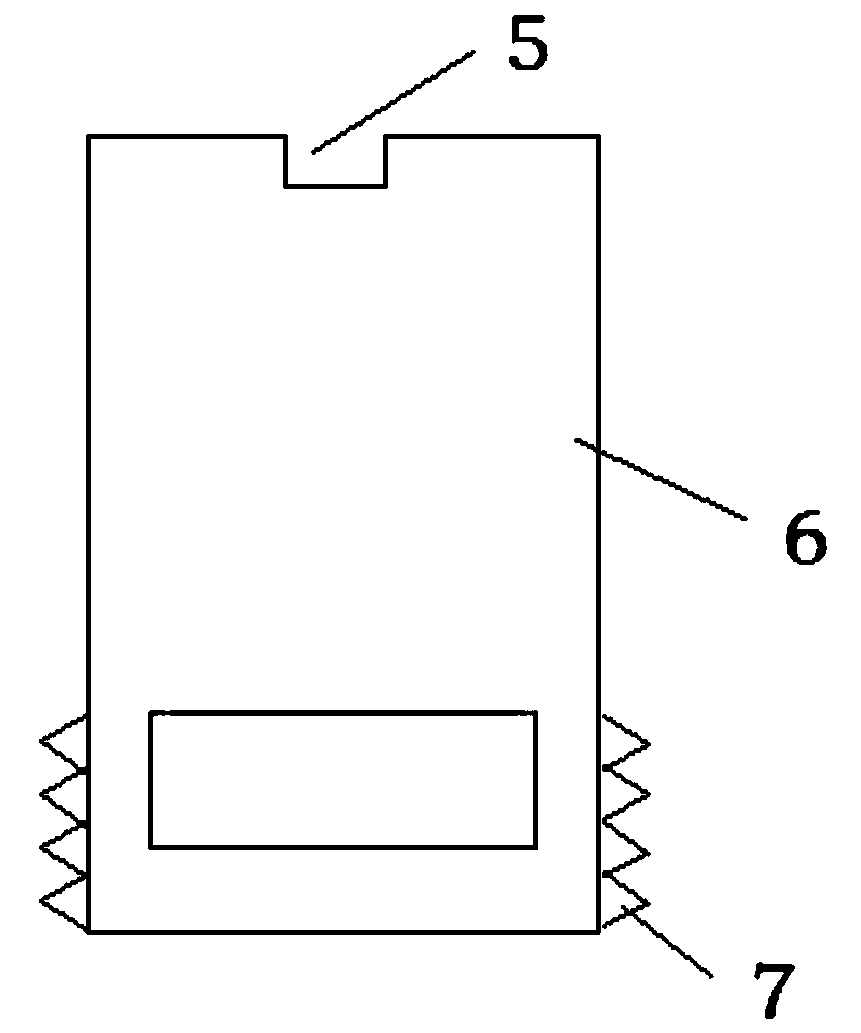

[0024] like Figures 1 to 4 As shown, a float valve core disassembly tool includes a rotating handle 1, a connecting rod 2, a centralizing ring 3 and a cross wrench 4, the top end of the connecting rod 2 is connected with a rotating handle 1, and the lower end is connected with a cross wrench 4, A centralizing ring 3 is provided on the connecting rod 2 between the rotary handle 1 and the cross wrench 4 .

[0025] The rotary handle 1 is a cylindrical alloy steel bar, the diameter of its circular section is 20-30 mm, and the length is twice the outer diameter of the external thread float valve core 6 used in conjunction with it. The connecting rod 2 is Cylindrical alloy steel bar, the diameter of its circular section is 20-30 mm, and the length is 100 mm higher than the upper end surface of the internal thread float valve joint 10 afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com