Measurement system and method for two-phase flow flow and dryness

A measurement system and phase flow technology, which is applied in the direction of measuring devices, detecting fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, etc., can solve the difficulties of flow and dryness, large measurement errors, and complex flow patterns Change and other problems, to achieve broad application prospects, to meet the effect of fast measurement, high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below through implementation examples, but the embodiments of the present invention are not limited thereto.

[0038] The system and method for measuring the flow rate and dryness of the two-phase flow of the present invention use the principle of thermodynamics to measure the flow rate and dryness by heating the fluid twice. When working, the two-phase flow circuit to be measured is cut off, and one end of the cut-off is the front-end interface, and the other end is the back-end interface. When in use, the measurement system is connected between the front-end interface and the back-end interface of the two-phase flow circuit.

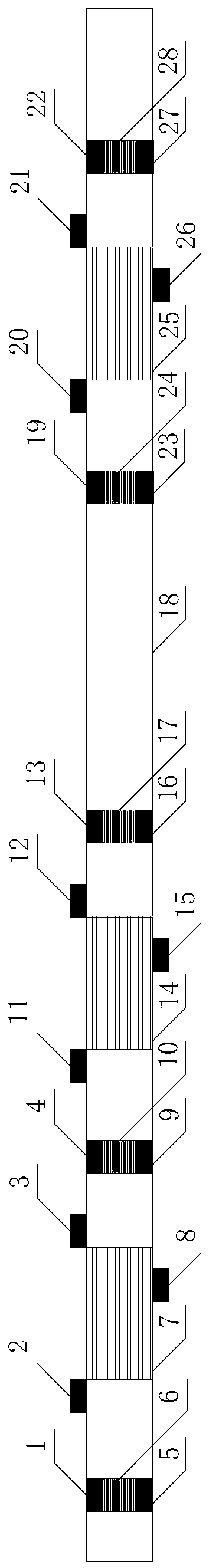

[0039] In the present invention, the measurement system of two-phase flow and dryness is as figure 1 As shown, the two-phase flow circuit includes a first pipeline, a second pipeline and a third pipeline connected sequentially along the direction of the flow path, and a cooling pipeline is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com