Photoresist, preparation method and photolithography process thereof

A photolithography process and photoresist technology, applied in the field of photolithography, can solve the problems of human body hazards and high toxicity, and achieve the effects of easy operation, improved adhesion and good adhesion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

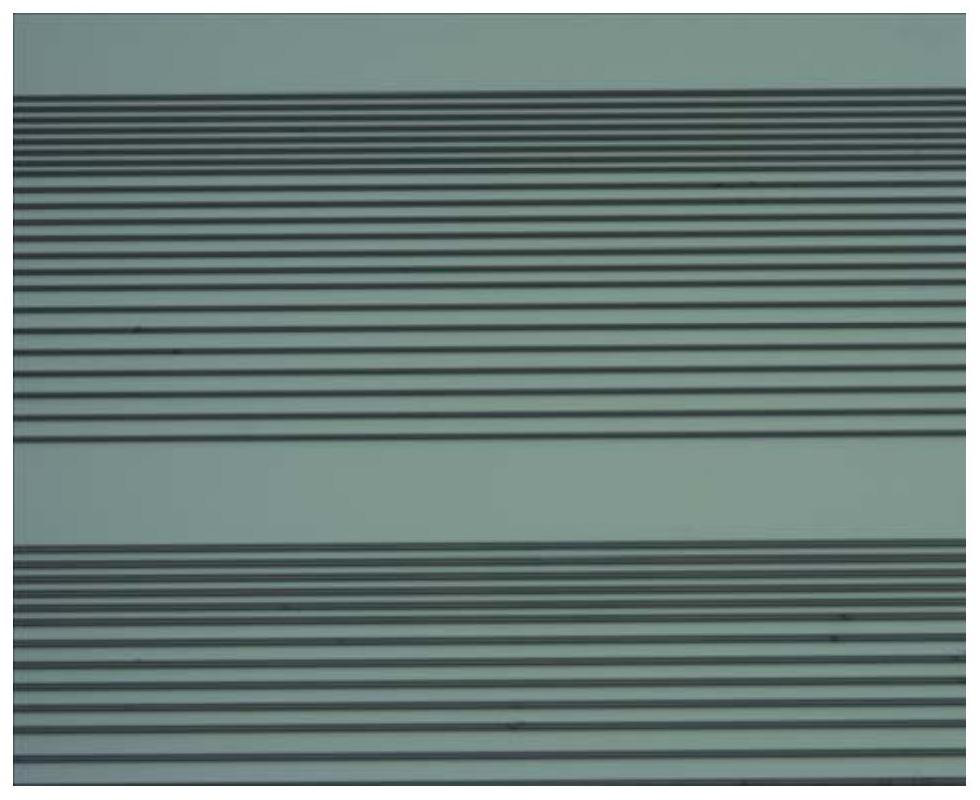

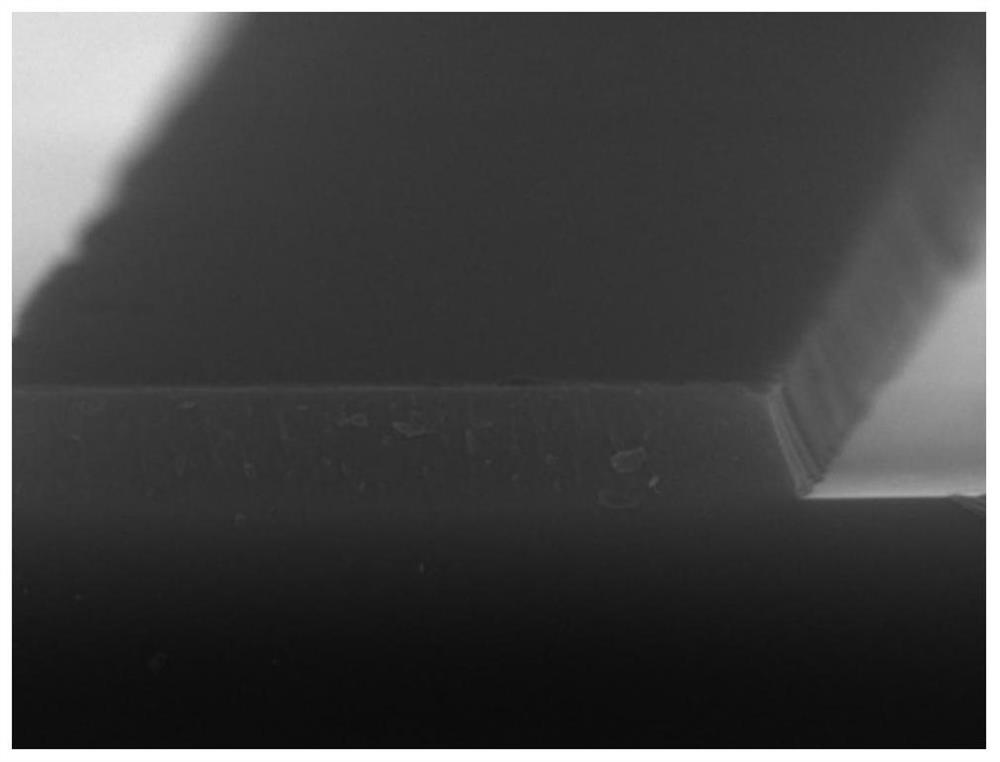

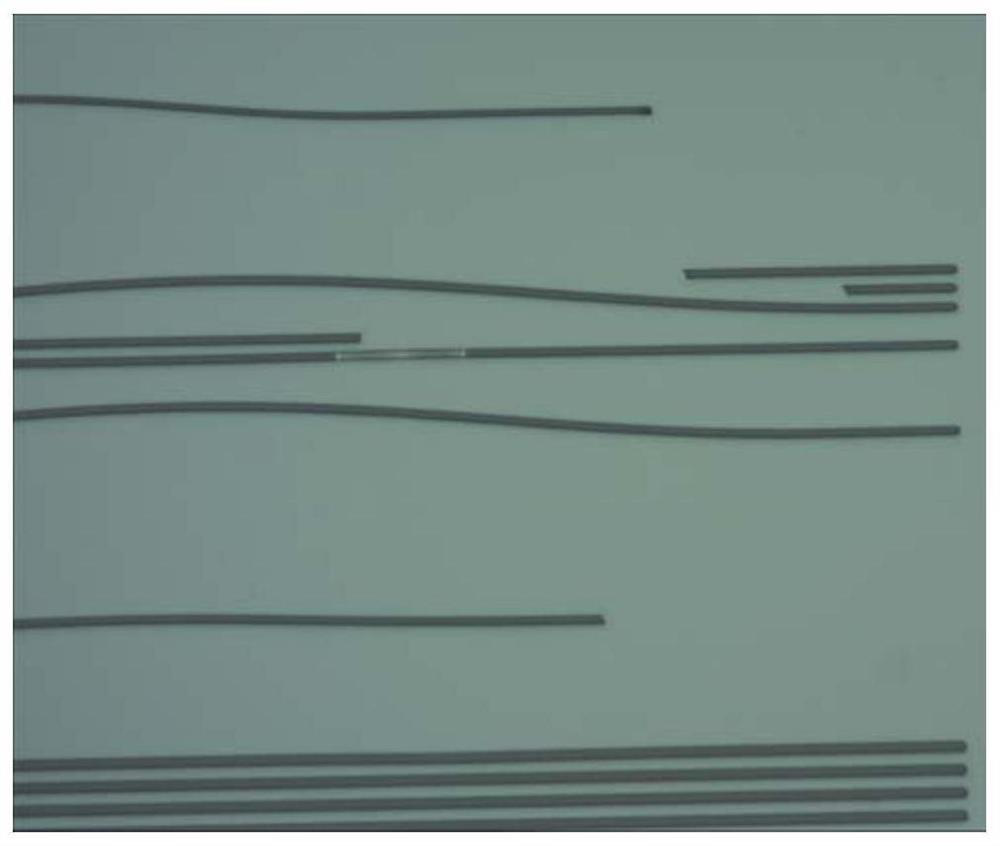

Image

Examples

Embodiment 1

[0047] The composition of the photoresist of the present embodiment is:

[0048] 19.68g of large molecular weight resin, 4.92g of small molecular weight resin, 5.4g of 2,1,4-diazonaphthoquinone sulfonate, 1.5g of United Carbide A-1100, 68.5g of propylene glycol methyl ether acetate.

[0049] Wherein, the high molecular weight resin has a structural unit The resin, wherein, the number of repeating units is 85; the low molecular weight resin has a general structural formula Wherein, the number of repeating units is 16.

[0050] The specific steps of the preparation method of the photoresist are as follows: the above-mentioned components are mixed, fully dissolved, and then filtered through a filter membrane with a pore size of 0.02 μm to obtain the photoresist.

[0051] The specific steps of the photolithography process of the photoresist are as follows: spin-coat the above-mentioned photoresist on the treated silicon wafer, pre-bake it with a hot plate, and pre-bake it at 1...

Embodiment 2

[0053] The composition of the photoresist of the present embodiment is:

[0054] 18.72g of large molecular weight resin, 4.68g of small molecular weight resin, 6.6g of 2,1,5-diazonaphthoquinone sulfonate, 1g of Chinese Academy of Sciences KH-550, 69g of propylene glycol methyl ether acetate.

[0055] Wherein, the high molecular weight resin has a structural unit The resin, wherein, the number of repeating units is 50; the small molecular weight resin has a general structural formula Wherein, the number of repeating units is 9.

[0056] The specific steps of the preparation method of the photoresist are as follows: the above-mentioned components are mixed, fully dissolved, and then filtered through a filter membrane with a pore size of 0.02 μm to obtain the photoresist.

[0057] The specific steps of the photolithography process of the photoresist are as follows: spin-coat the above-mentioned photoresist on the treated silicon wafer, pre-bake it with a hot plate, and pre-ba...

Embodiment 3

[0059] The composition of the photoresist of the present embodiment is:

[0060] 17.01g of large molecular weight resin, 7.29g of small molecular weight resin, 5.7g of 2,1,4-diazonaphthoquinone sulfonate, 1.5g of Dow Corning Z-6011, and 68.5g of propylene glycol methyl ether acetate.

[0061] Wherein, the high molecular weight resin has a structural unit The resin, wherein, the number of repeating units is 85; the low molecular weight resin has a general structural formula Wherein, the number of repeating units is 9.

[0062] The specific steps of the preparation method of the photoresist are as follows: the above-mentioned components are mixed, fully dissolved, and then filtered through a filter membrane with a pore size of 0.02 μm to obtain the photoresist.

[0063] The specific steps of the photolithography process of the photoresist are as follows: spin-coat the above-mentioned photoresist on the treated silicon wafer, pre-bake it with a hot plate, and pre-bake it at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com