A kind of double-layer composite diaphragm battery and its lithium replenishment method

A double-layer composite, diaphragm battery technology, applied in secondary batteries, battery pack components, electrolyte battery manufacturing, etc., can solve the problems of unstable SEI film, uncontrollable lithium insertion speed, and rupture of negative electrode materials, and avoid the need for compensation. The lithium process and lithium replenishment operation are simple and convenient, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

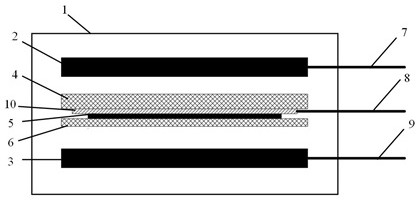

[0027] Such as figure 1 As shown, this embodiment provides a double-layer composite diaphragm battery, including a casing 1 , a positive electrode 2 , a negative electrode 3 , a double-layer composite diaphragm, and an electrolyte (not shown in the figure) inside the casing 1 . The double-layer composite separator includes a first separator 4, an active lithium layer 5 and a second separator 6, and is located between the positive electrode 2 and the negative electrode 3, and insulates the positive electrode and the negative electrode, wherein the active lithium layer 5 is between Between the first diaphragm 4 and the second diaphragm 6 . The positive electrode 2, the negative electrode 3 and the active lithium layer 5 are electrically connected to one end of the positive electrode tab 7, the lithium supplementary tab 8, and the negative electrode tab 9 respectively, and the other ends can all extend out of the casing 1 or only the positive electrode tab and The negative pole ...

Embodiment 2

[0045] Such as figure 2 As shown, the double-layer composite diaphragm battery provided in this embodiment can also be provided with a conductive coating 10 between the first diaphragm 4 and the active lithium layer 5 and / or between the second diaphragm 6 and the active lithium layer 5, the A conductive coating 10 is in contact with said active lithium layer 5 . The lithium-supplementing tab 8 is no longer in direct contact with the active lithium layer 5 , but is in direct contact with the conductive coating 10 . The rest of the structure of the double-layer composite diaphragm battery provided in this embodiment is completely the same as that in Embodiment 1.

[0046] According to the double-layer composite diaphragm battery provided in this embodiment, when lithium is replenished, the active lithium layer 5 is conducted to the lithium replenishing tab through the conductive coating 10, and then passes through the positive electrode tab or the negative electrode connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com