Reactive compensation system

A compensation system and capacitor technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, AC network circuits, etc., can solve problems such as inconvenient installation and maintenance, complexity, poor economy, etc., to facilitate expansion and maintenance , Reduce the number of components and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

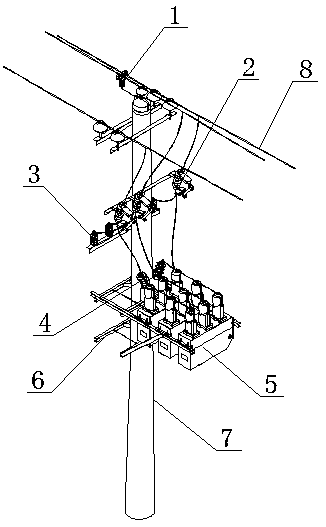

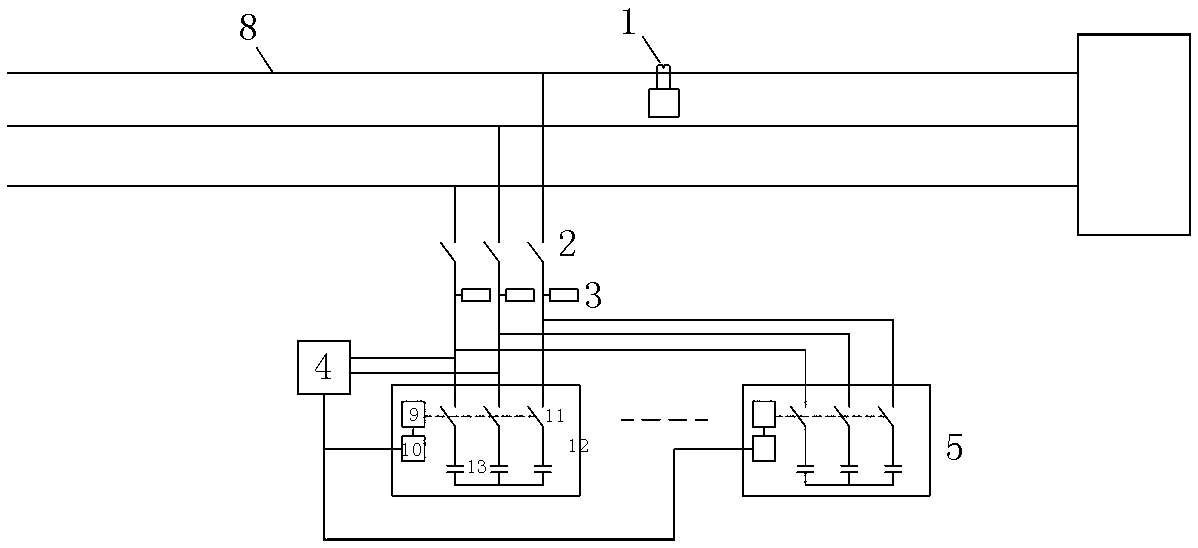

[0021] As shown in the figure, a reactive power compensation system of the present invention includes a current transformer 1, a switch 2, an arrester 3, a voltage transformer 4 and several groups of combined capacitors 5, a current transformer 1, a switch 2, an arrester 3, a voltage The transformer 4 and the combination capacitor 5 are all fixed on the wire column 7 through the bracket 6, the current transformer 1 is arranged on the three-phase transmission line 8 and connected with the combination capacitor 5, several groups of combination capacitors 5 are connected in parallel and each group of combination capacitor 5 The three phases are respectively connected to the three-phase output end of the switch 2, the three-phase input end of the switch 2 is connected to the three-phase transmission line 8, and the three lightning arresters 3 are respectively arranged on the three-phase connection line between the switch 2 and the combined capacitor 5, and the voltage transformer 4...

Embodiment 2

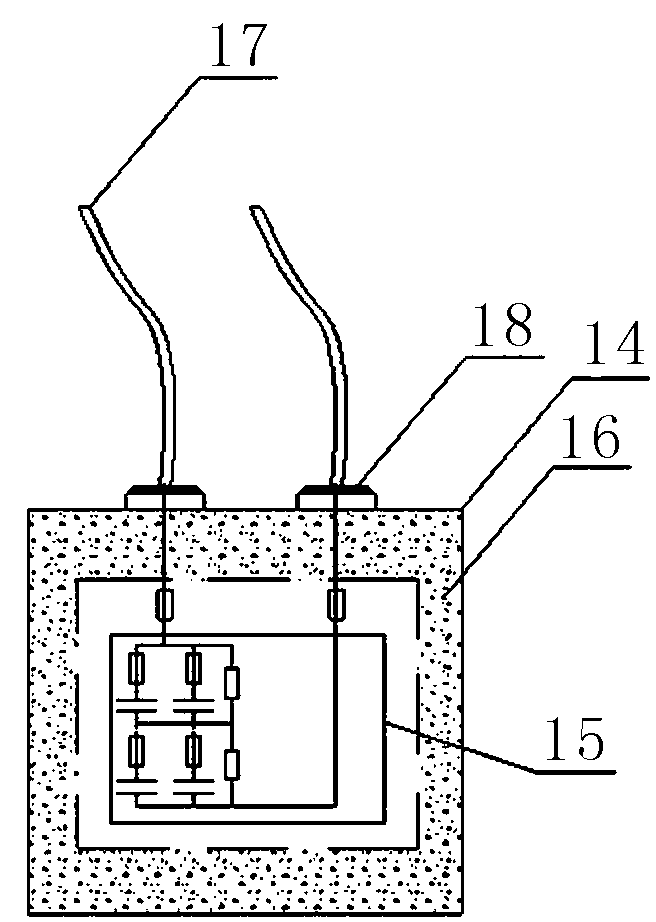

[0027] A reactive power compensation system, current transformer 1, switch 2, lightning arrester 3, voltage transformer 4 and several groups of combined capacitors 5, current transformer 1, switch 2, lightning arrester 3, voltage transformer 4 and combined capacitor 5 are all passed through The bracket 6 is fixed on the wire column 7, the current transformer 1 is arranged on the three-phase transmission line 8 and connected with the combination capacitor 5, several groups of combination capacitors 5 are connected in parallel and each group of combination capacitor 5 is three-phase output with the switch 2 respectively. The three-phase input terminal of the switch 2 is connected to the three-phase transmission line 8, and the three arresters 3 are respectively arranged on the three-phase connection line between the switch 2 and the combined capacitor 5, and the voltage transformer 4 is respectively connected to the three-phase input of the combined capacitor 5 The combined capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com