scroll compressor

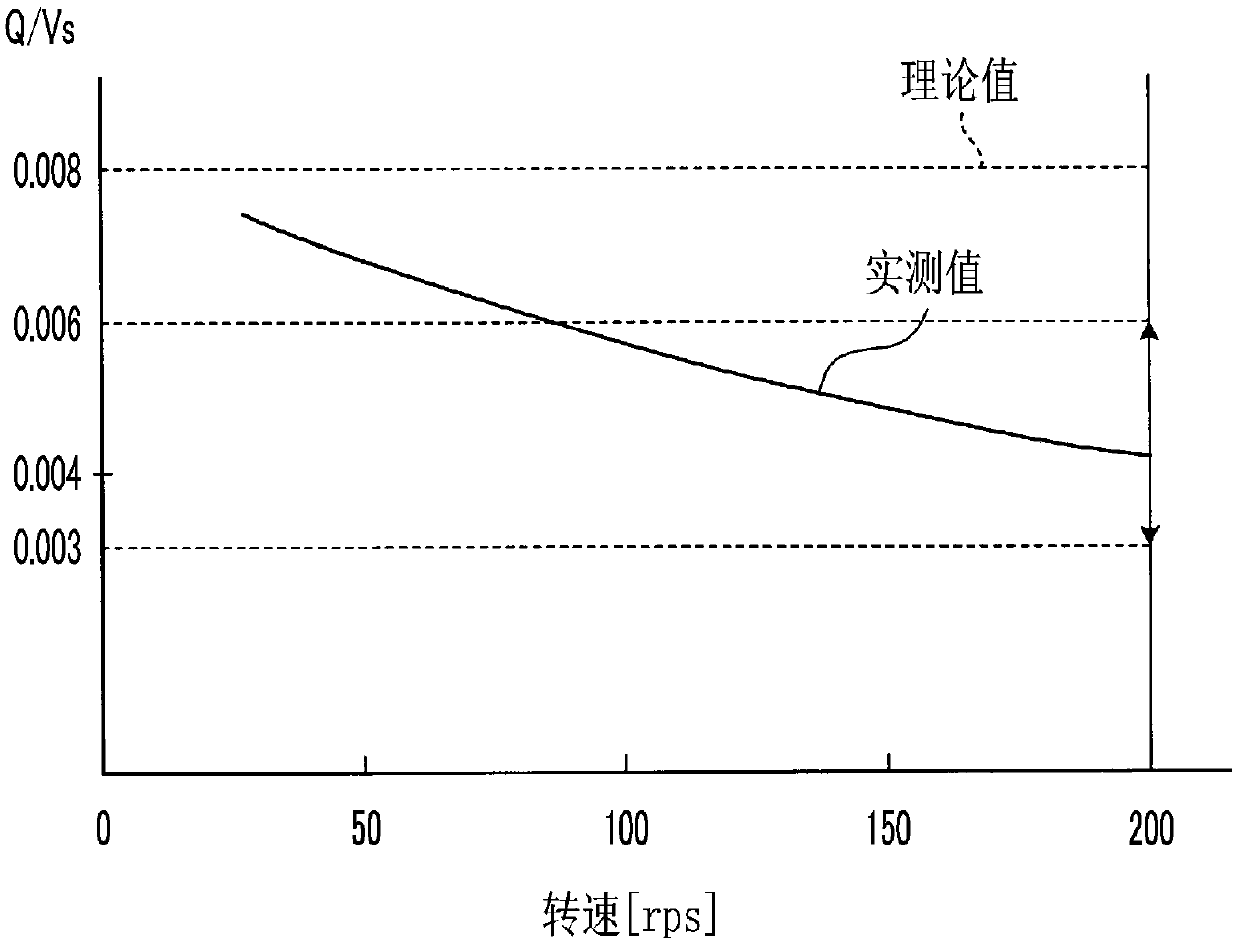

A scroll compressor and compression mechanism technology, applied in the field of scroll compressors, can solve problems such as the reduction of compressor operating efficiency, and achieve the effects of reducing the amount of lubricating oil, restraining the supply amount, and restraining the reduction of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments according to the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited to this embodiment. In addition, the constituent elements in the following embodiments include those that can be easily replaced by those skilled in the art, or those that are substantially the same.

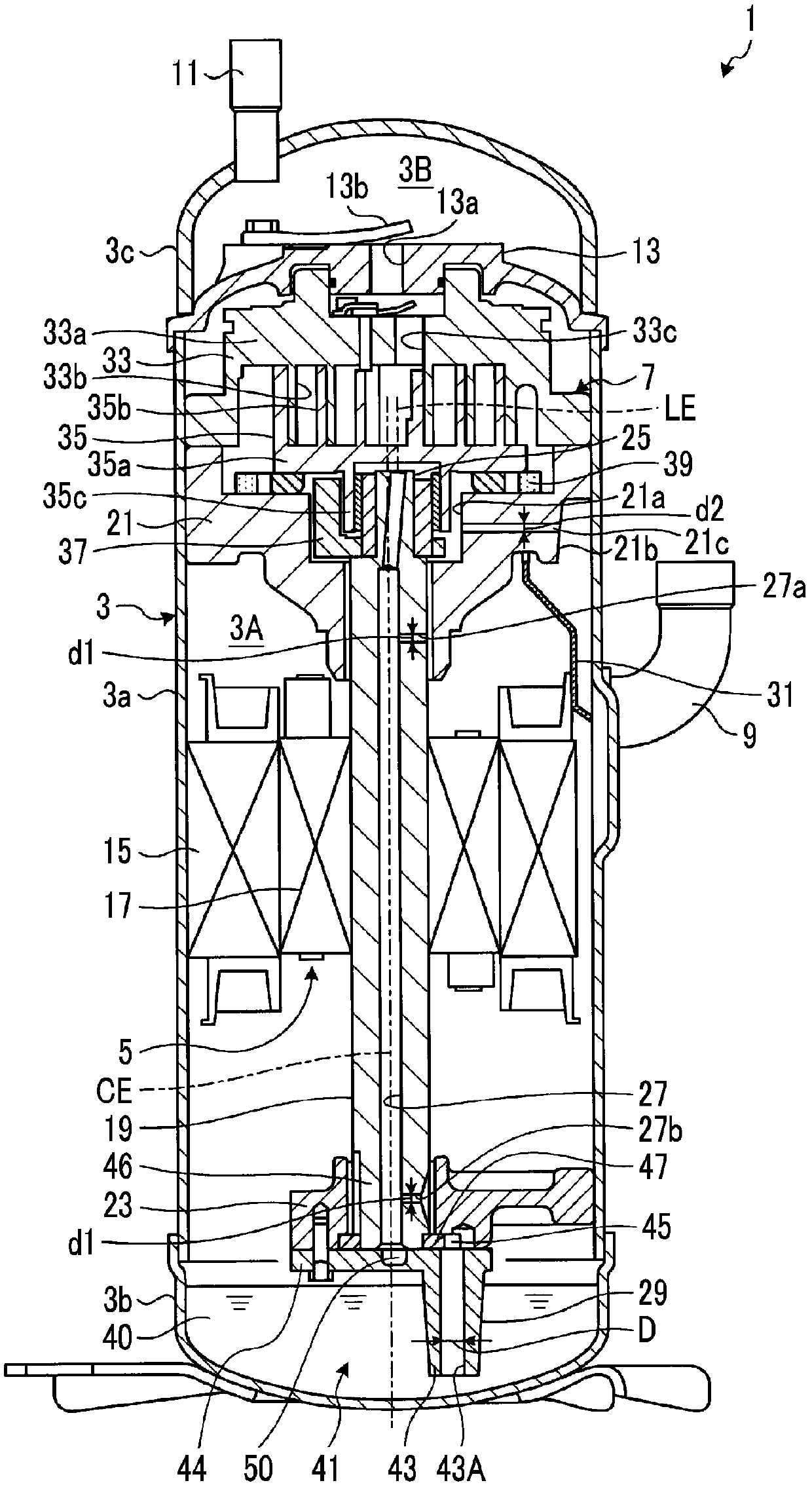

[0025] figure 1 It is an overall sectional view of the scroll compressor according to the present embodiment. The scroll compressor 1 compresses and sucks in a fluid (for example, refrigerant) and discharges it. In the present embodiment, the scroll compressor 1 is interposed in a refrigerant flow path that circulates the refrigerant in an air conditioner, refrigeration device, or the like.

[0026] Such as figure 1 As shown, the scroll compressor 1 includes a motor (drive motor) 5 as a drive configuration and a scroll compression mechanism 7 driven by the motor 5 inside a casing 3 .

[0027] The casing 3 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com