Multi-disk arrangement for a multi-disk clutch

A friction plate and clutch technology, which is applied to the friction plate device and the field of assembling the friction plate device, can solve the problems of increasing the pressing force, not providing and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

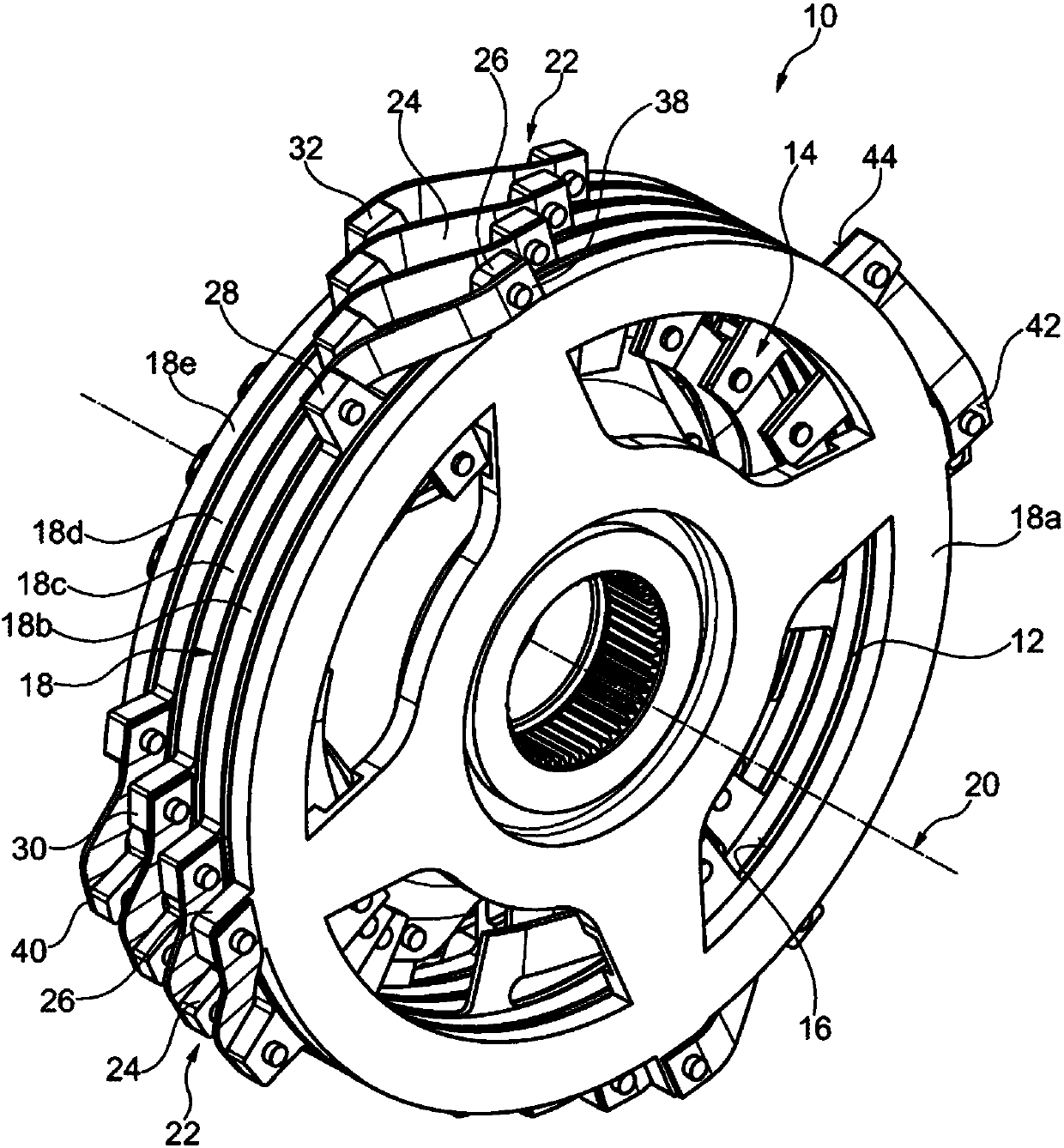

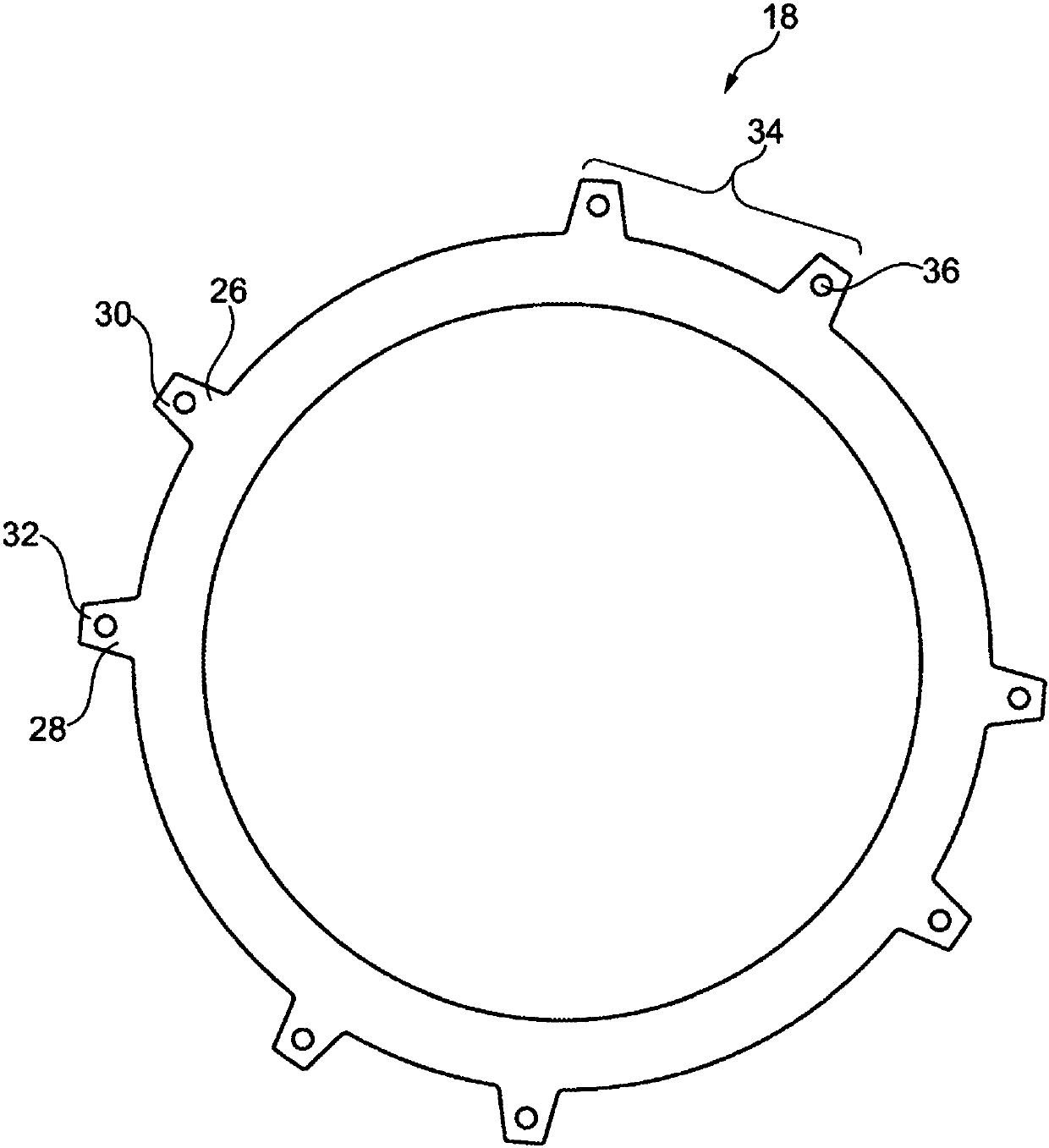

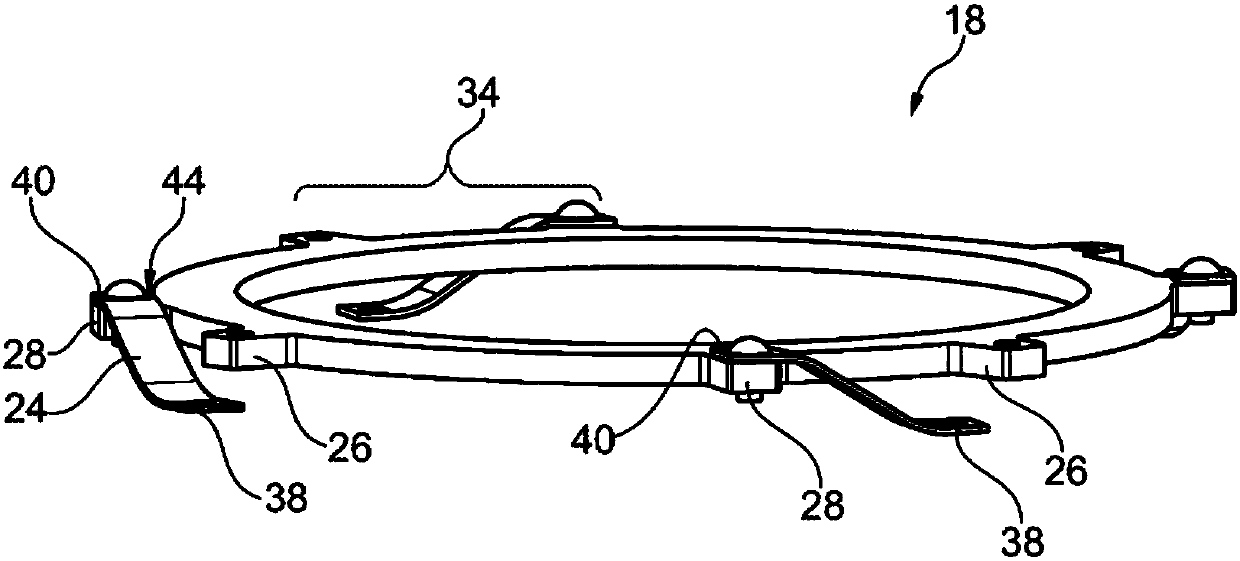

[0031] figure 1 A perspective general view of a friction lining arrangement 10 according to one embodiment of the invention is shown. In this exemplary embodiment, the lining arrangement 10 is provided with four annular inner linings 12 arranged parallel to one another. In order to connect the inner disks 12 to one another, the disk arrangement 10 has an inner connecting device 14 which is arranged on an inner circumference 16 of the inner disks 12 . as in figure 1 As shown in , the friction lining device 10 also has five annular outer friction linings 18 arranged parallel to the inner friction lining 12 for pressing the inner friction lining 12 with a friction fit. The inner disks 12 and the outer disks 18 are arranged alternately and axially displaceable relative to one another and have the same axis of rotation 20 . In order to connect the outer disks 18 to one another, the disk arrangement 10 has an outer connecting device 22 which is arranged on an outer circumference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com