Forming milling cutter for online rail repair

A technology for forming milling cutters and rails, which is applied in the direction of milling cutters, milling machine equipment, metal processing equipment, etc., can solve the problems of line environmental pollution, small single-pass workload, etc., and achieve reduced workload, stable repair quality, and consistent molded lines sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

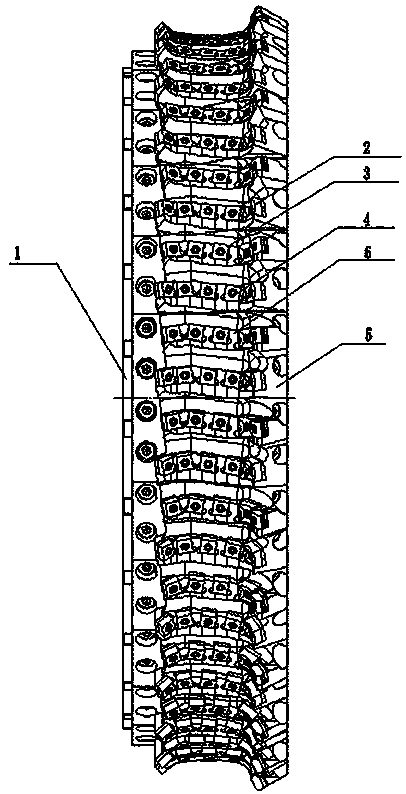

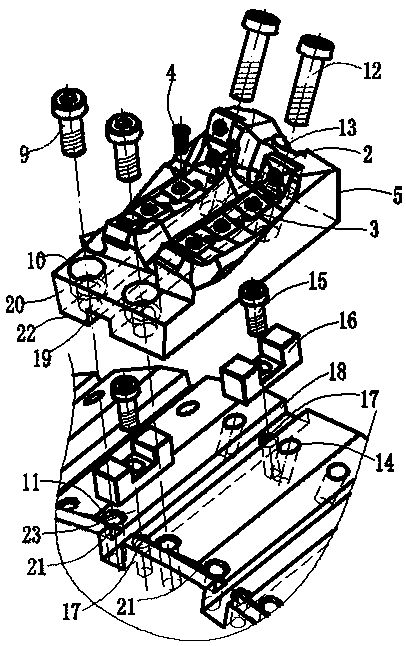

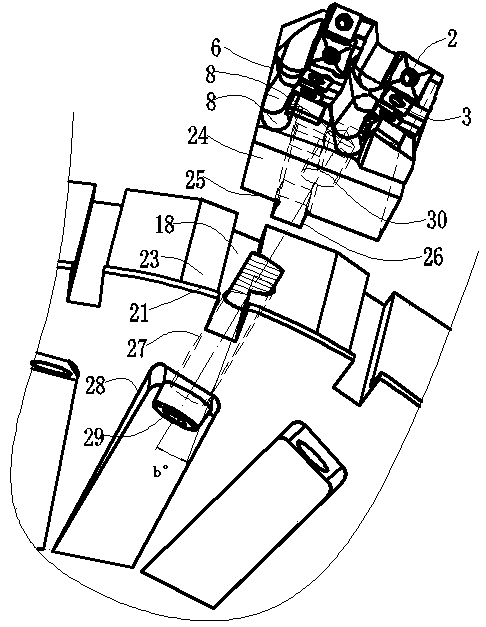

[0022] Such as figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 8 As shown, it consists of a cutter body 1, a blade, a blade pressing screw 4 and a side cutter seat 5, wherein the blade includes a circular arc blade 2 and a straight blade 3, and multiple rows of blades overlap each other in space to form a The blade overlaps the profile line 31 to form a complete cutting edge on the working surface of the rail. The cutter body 1 is fixed on the central axis and rotates with the central axis. The circumference of the cutter body 1 is provided with several radial positioning surfaces 23 and axial positioning surfaces 21 , each radial positioning surface 23 of the cutter body 1 has a threaded hole, and the circumference of the cutter body 1 is also provided with a cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com