3D photo-curing printing method for inner suspended wall face of hollow object

An object, hollow technology, applied in the field of 3D printing, can solve the problem of the bracket remaining inside the object, and achieve the effect of avoiding the residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable your review committee members to have a further understanding and understanding of the purpose, characteristics and effects of the present invention, the specific implementation methods and drawings are described in detail as follows:

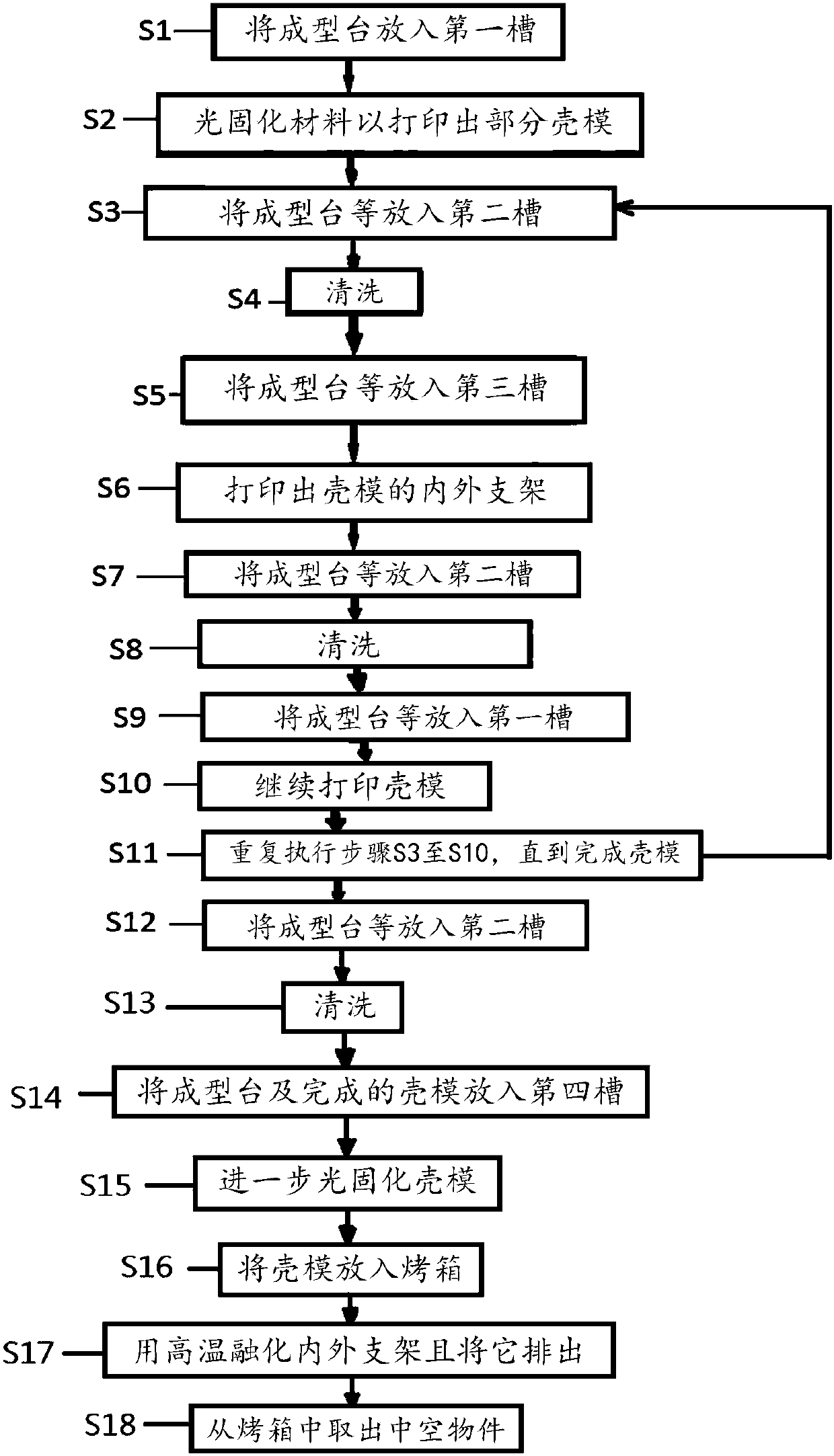

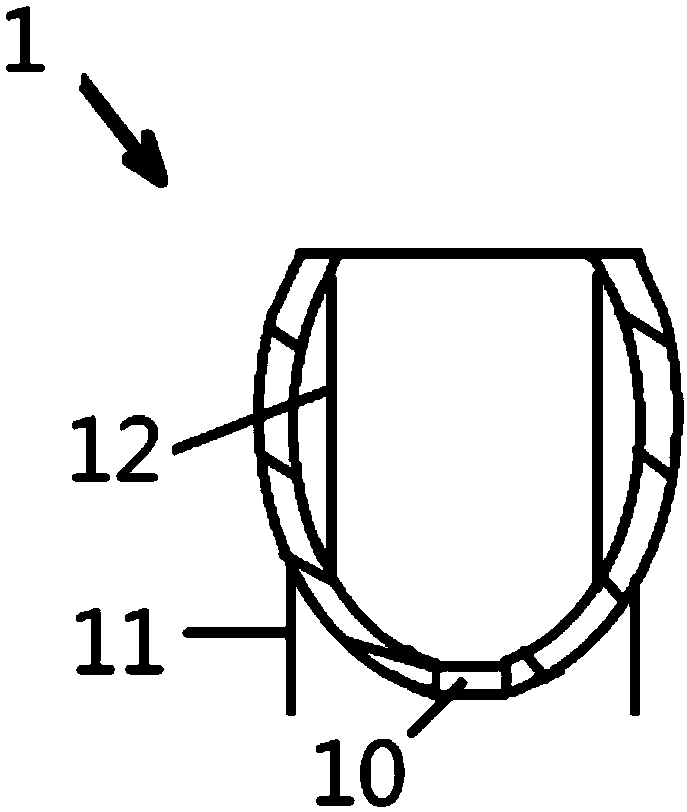

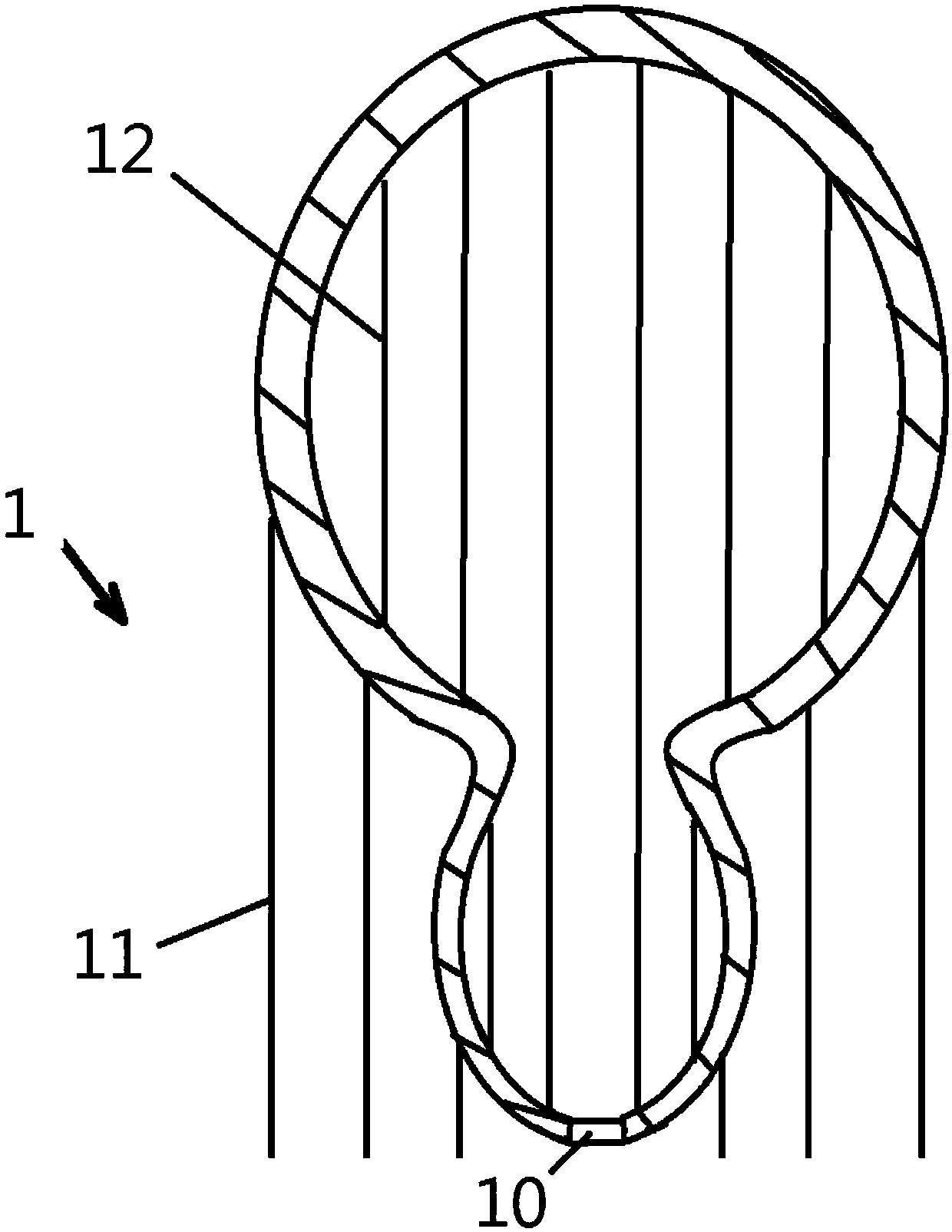

[0034] refer to Figure 1 to Figure 5 , the 3D light curing printing method of the inner suspended wall of the hollow object of the present invention, comprising the following steps:

[0035] S1: Start the rotating device 30 and the lifting device 31 to put the molding table 32 into the first tank 20, which is filled with the first liquid material (such as high melting point ceramic slurry);

[0036] S2: Start the light curing machine 4 to emit light to cure a specific part of the first liquid material, so as to print a part of the shell mold 1 on the upper surface of the forming table 32, that is, the solid unfinished shell mold 1, remarks: In another example, it is also possible to print a part of the shell mold 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com