Watertight isolated ship ventilation system

A ventilation system, watertight technology, applied in the direction of hull ventilation/heating/cooling, ships, ship components, etc., can solve the problem of endangering the vitality of ships and equipment technical performance, interruption of power system and power system output, affecting the ventilation effect of ventilation system, etc. problem, to achieve good sealing effect, maintenance and stable operation, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

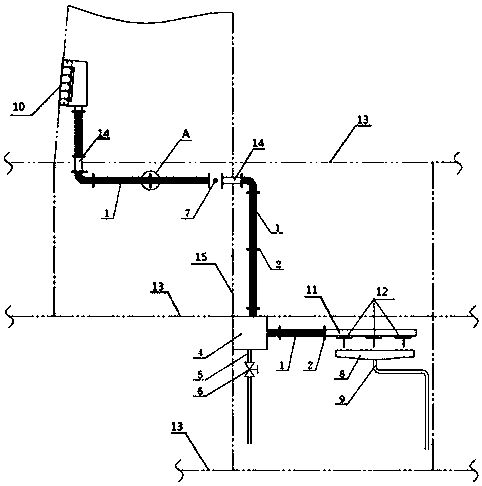

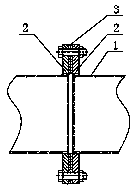

[0036] Example: such as Figure 1 to Figure 4 As shown, a watertight isolation ship ventilation system includes an external vent 10, a main vent pipe, a terminal vent pipe 11 and a terminal vent 12, and the two ends of the main vent pipe are connected to the external vent 10 and the terminal vent pipe respectively. 11 connection, the end air outlet 12 is set under the end ventilation pipe 11, the main ventilation pipe is spliced by multiple sections of air pipes 1, and two adjacent sections of air pipes 1 are connected by watertight flanges 2.

[0037] In this embodiment, the main ventilation pipe is provided with a ventilation enclosure 4, the ventilation enclosure 4 is arranged at the lowest point of the main ventilation pipe, and the bottom of the ventilation enclosure 4 is provided with a first drain pipe 5, The first drain pipe 5 is connected to the drainage system, and the first drain pipe 5 is provided with a shut-off valve 6 .

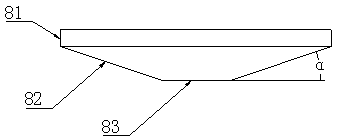

[0038] The bottom of the end tuyere 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com