A logistics pallet stacking and unstacking method

A pallet and logistics technology, applied in the direction of destacking, stacking, transportation and packaging of objects, can solve the problems of high work risk, limited stacking height, high labor intensity, etc., to achieve smooth movement, reduce The effect of labor intensity and safety assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

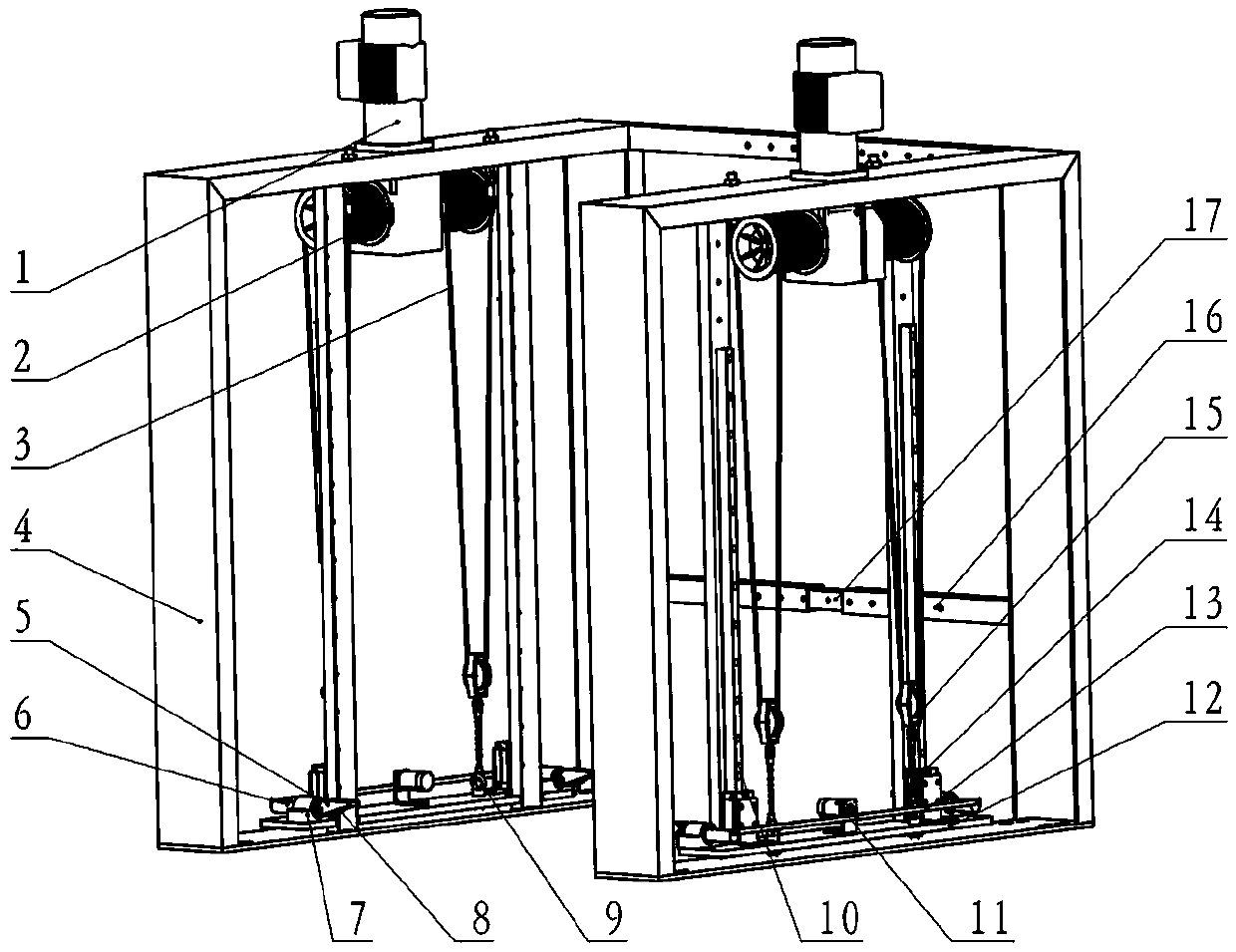

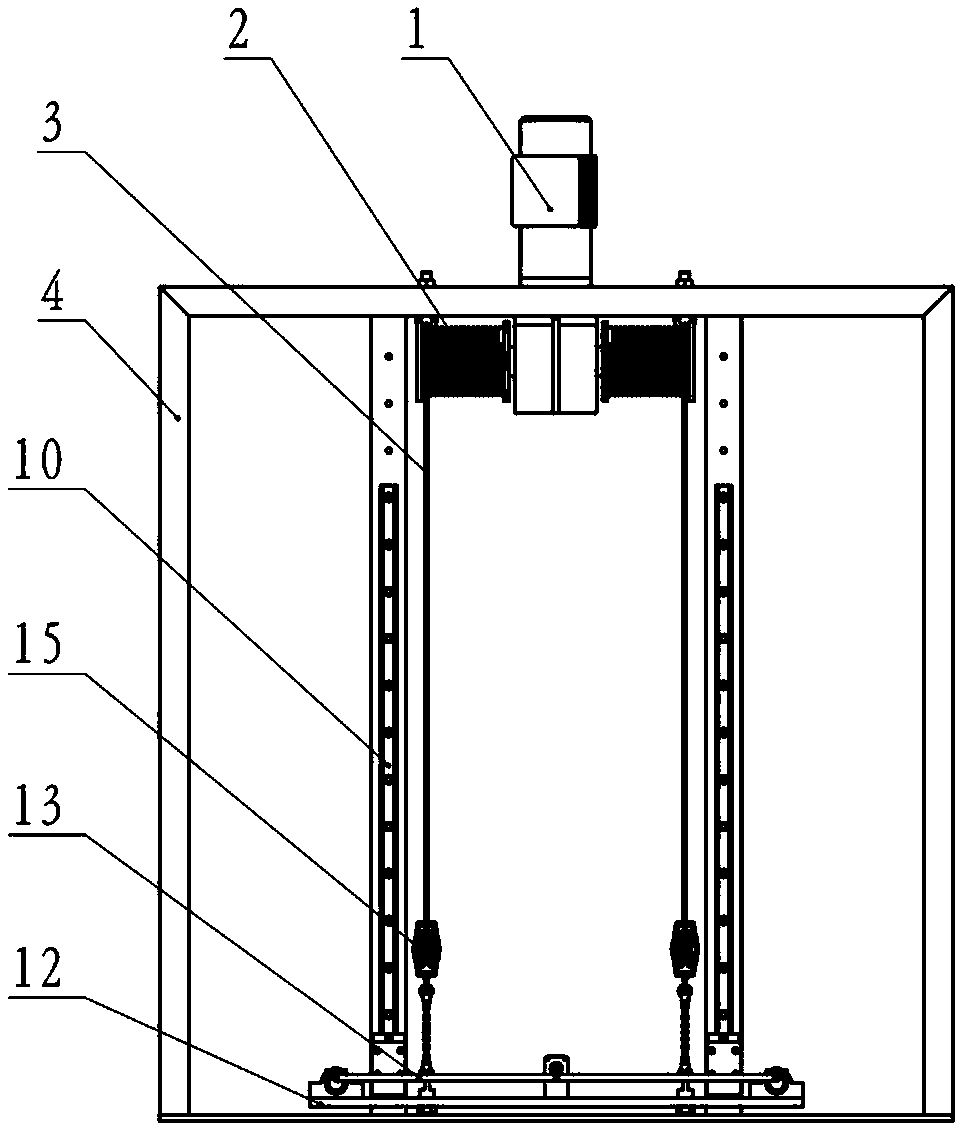

[0021] Such as figure 1 , 2 As shown, the logistics pallet stacking device adopted in the present invention includes a frame 4, a pallet lifting system and a pallet gripping system. Change the length of the square pipe 17 inserted into the square pipe 16 to meet the code division operation of pallets of different specifications.

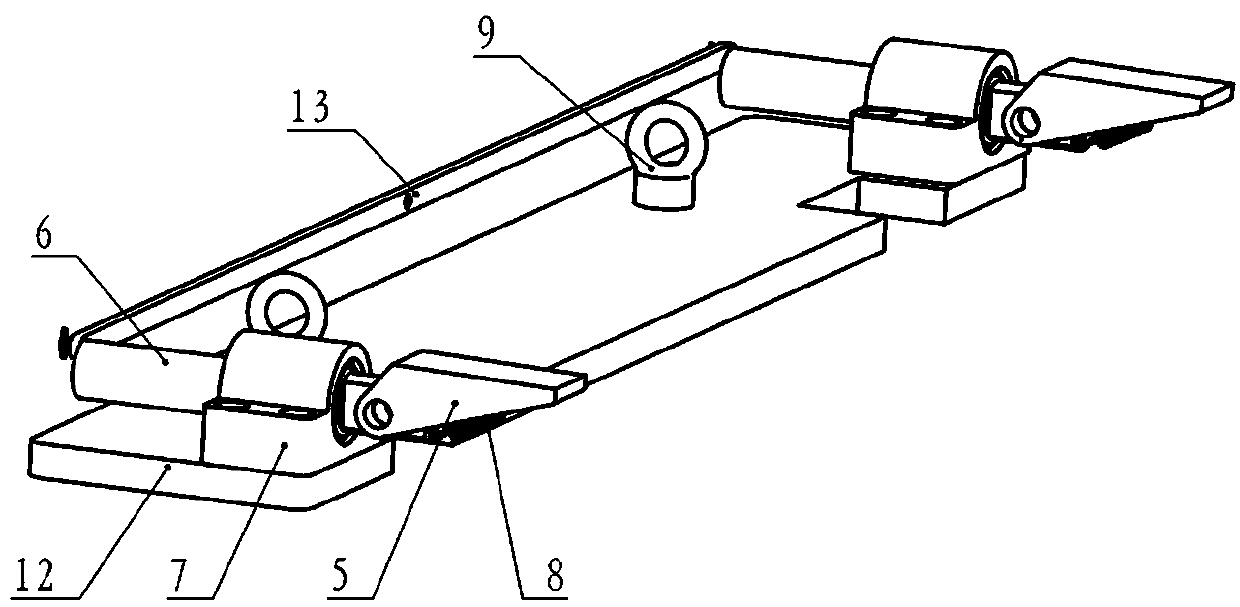

[0022] Such as image 3 As shown, the pallet grasping system includes a lifting platform 12, a steering reducer 11, a connecting rod 13 and a grasping device; the steering reducer 11 is installed on the lifting platform 12; the grasping device includes a claw 5, a pull Stretching spring 8, steering shaft 6, support seat 7, supporting claw 5 and steering shaft front 6 ends are hinged, and extension spring 8 two ends connect the bottom of supporting claw 5 and steering shaft 6 respectively. The steering shaft 6 is installed on the lifting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com