Oyster shell soil remediation agent and preparation method thereof

A technology of soil remediation agent and oyster shell, which is applied in the field of oyster shell soil remediation agent and its preparation, can solve the problems of secondary gas pollution, high cost of industrialization, and high treatment cost, and achieve the improvement of heavy metal adsorption capacity and large The micropore area and the effect of improving the composition of soil nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 component A oyster shell powder

[0033] 1.1 Preparation method

[0034] Preparation of Component A: Clean the oyster shells and remove the sediment; put the oyster shells into a high-temperature reactor for subcritical hydrolysis. 60 minutes; release the pressure and discharge; crush the subcritical hydrolyzed material into a powder smaller than 2mm to obtain the component A.

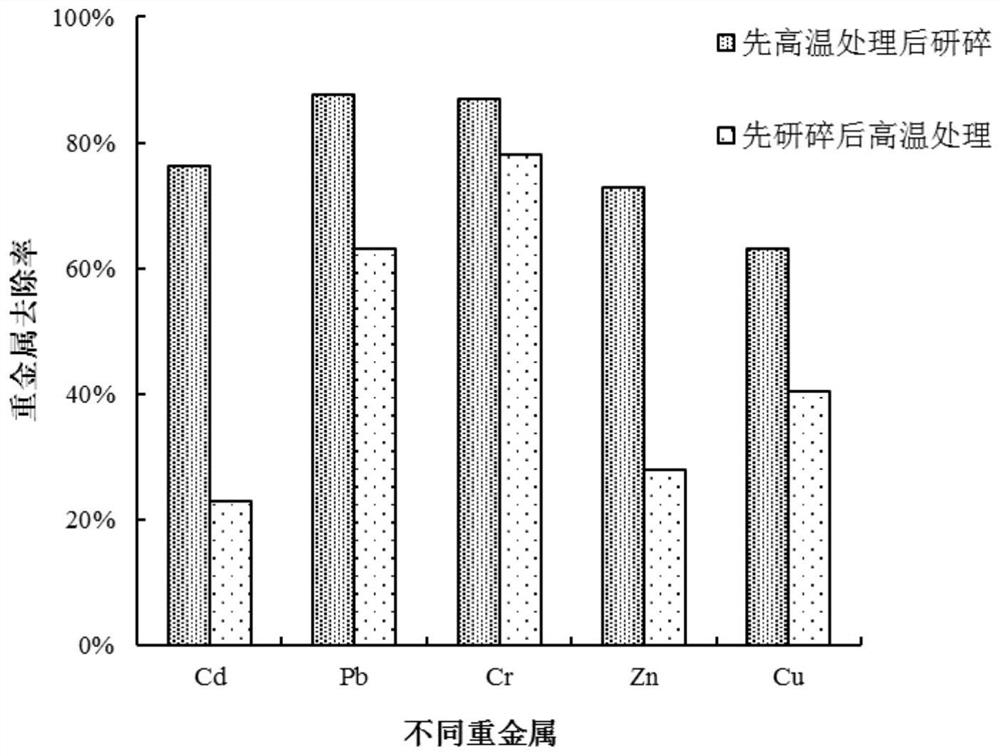

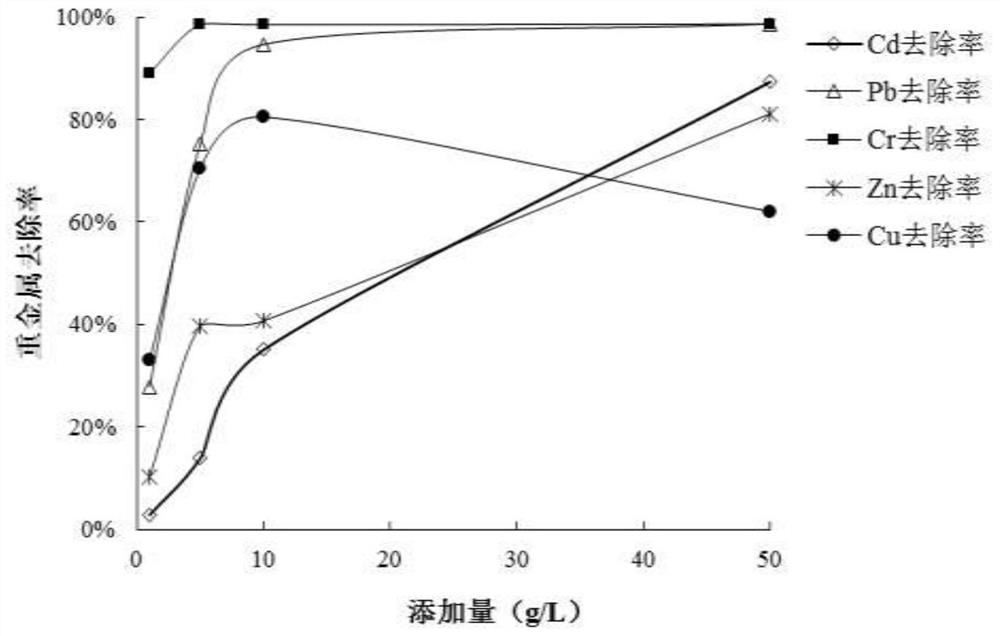

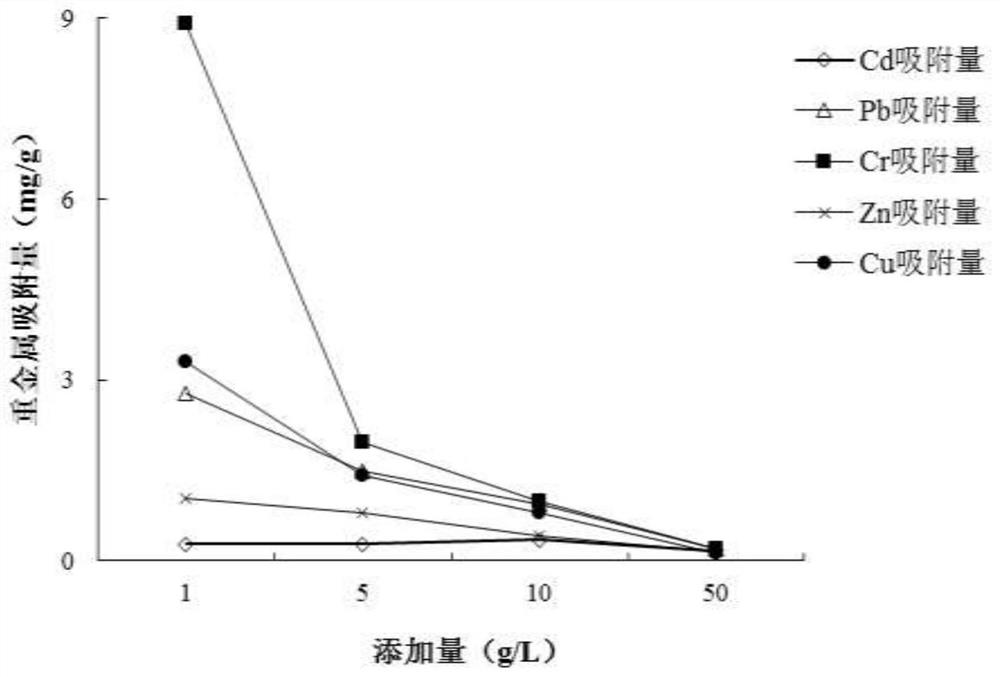

[0035] 1.1.1 Effect of subcritical hydrolysis treatment at different temperatures on the adsorption of heavy metals in oyster shell powder

[0036] Oyster shells treated at different temperatures (at normal temperature and pressure, 200°C 1.5Mpa; 250°C 3.2Mpa; 300°C 4.4Mpa for 1h) were ground and passed through a sieve with a diameter of 2 mm, and the oyster shell powder was weighed and added to the Concentration is respectively in the heavy metal solution of Cd, Pb, Cr, Zn of 1mg / L, the final volume of control solution is 50mL, the addition amount of oyster she...

Embodiment 2

[0067] The preparation of embodiment 2 component B

[0068] 2.1 Preparation method

[0069] Preparation of component B: Mix agricultural cellulose waste and pig manure in proportion to obtain a mixture; put the obtained mixture into a high-temperature reactor for subcritical hydrolysis, and the subcritical hydrolysis conditions are temperature 160°C-200°C, pressure 0.5 -2.0Mpa, the treatment time is 10min-30min; discharge the material by releasing the pressure; dry at 100°C for 2h; pulverize the obtained subcritical hydrolyzate into a powder smaller than 2mm to obtain component B.

[0070] Wherein, sample 1: agricultural cellulose waste: pig manure=20%wt:80%wt; subcritical hydrolysis condition is: 200 ℃, 2.0MPa;

[0071] Sample 2: Agricultural cellulose waste: pig manure=50%wt:50%wt; subcritical hydrolysis conditions are: 200°C, 2.0MPa,

[0072] Measure the nutrient substance content of component B, its result is as shown in table 5, table 6:

[0073] Table 5 Determination ...

Embodiment 3

[0084] Embodiment 3 oyster shell soil remediation agent 1

[0085] (1) Preparation of component A: clean the oyster shells and remove the sediment; put the oyster shells into a high-temperature reactor for subcritical hydrolysis, the subcritical hydrolysis conditions are temperature 220°C, pressure 2.6Mpa, and treatment time is 30min; depressurization Discharging: The component A is obtained by pulverizing the subcritical hydrolyzed material into a powder smaller than 2 mm.

[0086] (2) Preparation of component B: Mix agricultural cellulose waste and pig manure in proportion to obtain a mixture; put the obtained mixture into a high-temperature reactor for subcritical hydrolysis, and the subcritical hydrolysis conditions are temperature 200°C and pressure 2.0Mpa , the treatment time is 20min; the material is discharged under pressure release; drying at 100°C for 2h; the obtained subcritical hydrolyzate is pulverized into a powder smaller than 2mm to obtain component B;

[0087...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com