Hanging system for mould overall removing of upgoing type movable formwork

A technology of moving formwork and formwork, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems of long time spent on formwork removal, difficult removal of formwork of mobile formwork, and safety accidents easily caused by bolts, etc., to achieve Improve demolition efficiency, reduce risk, and achieve reasonable weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

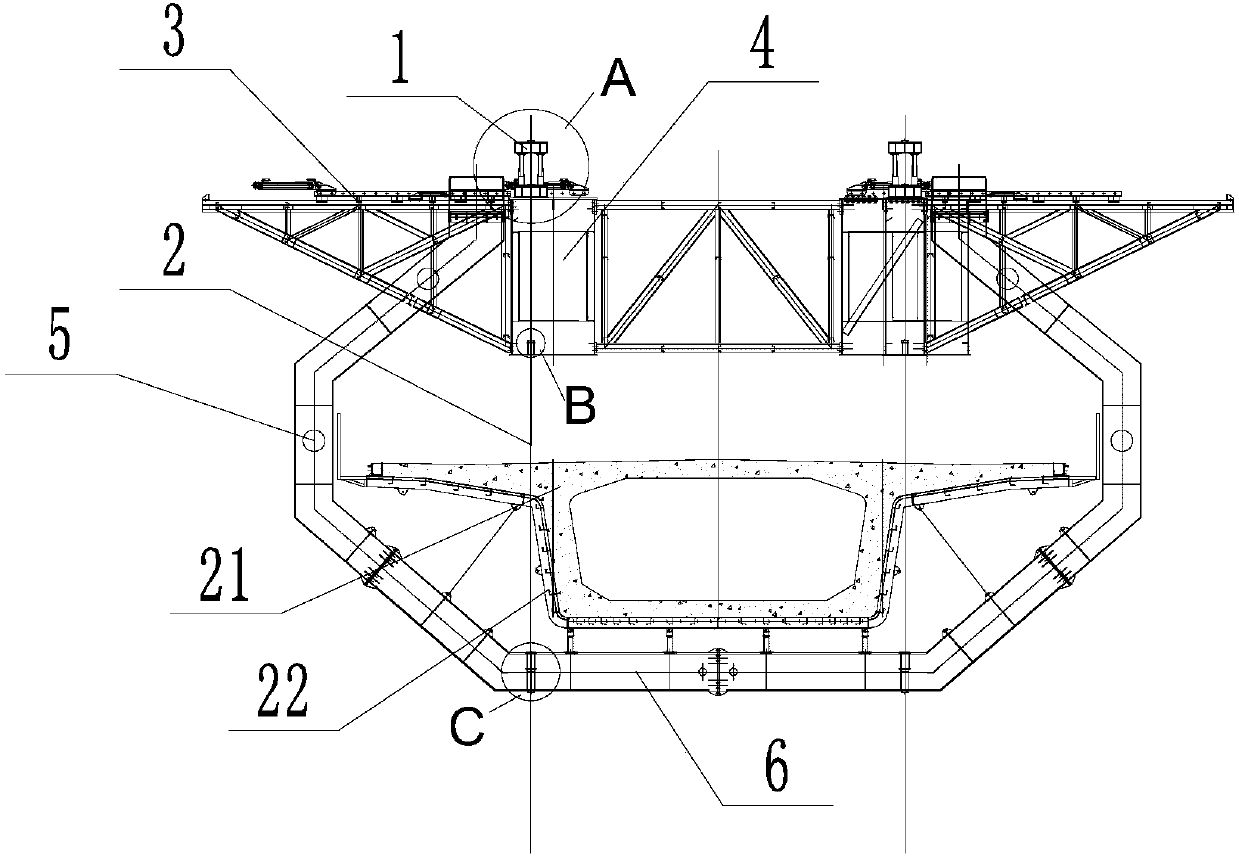

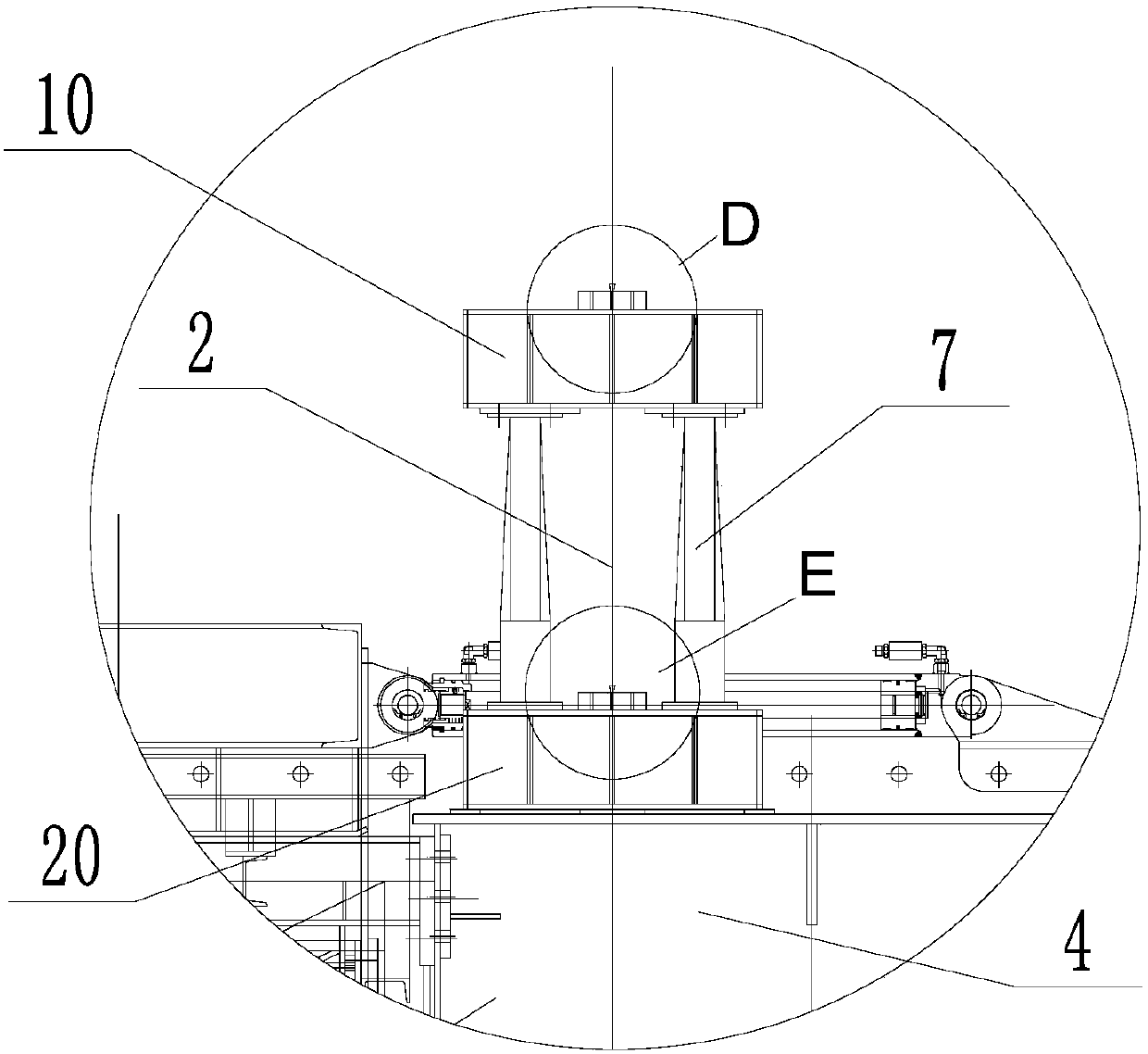

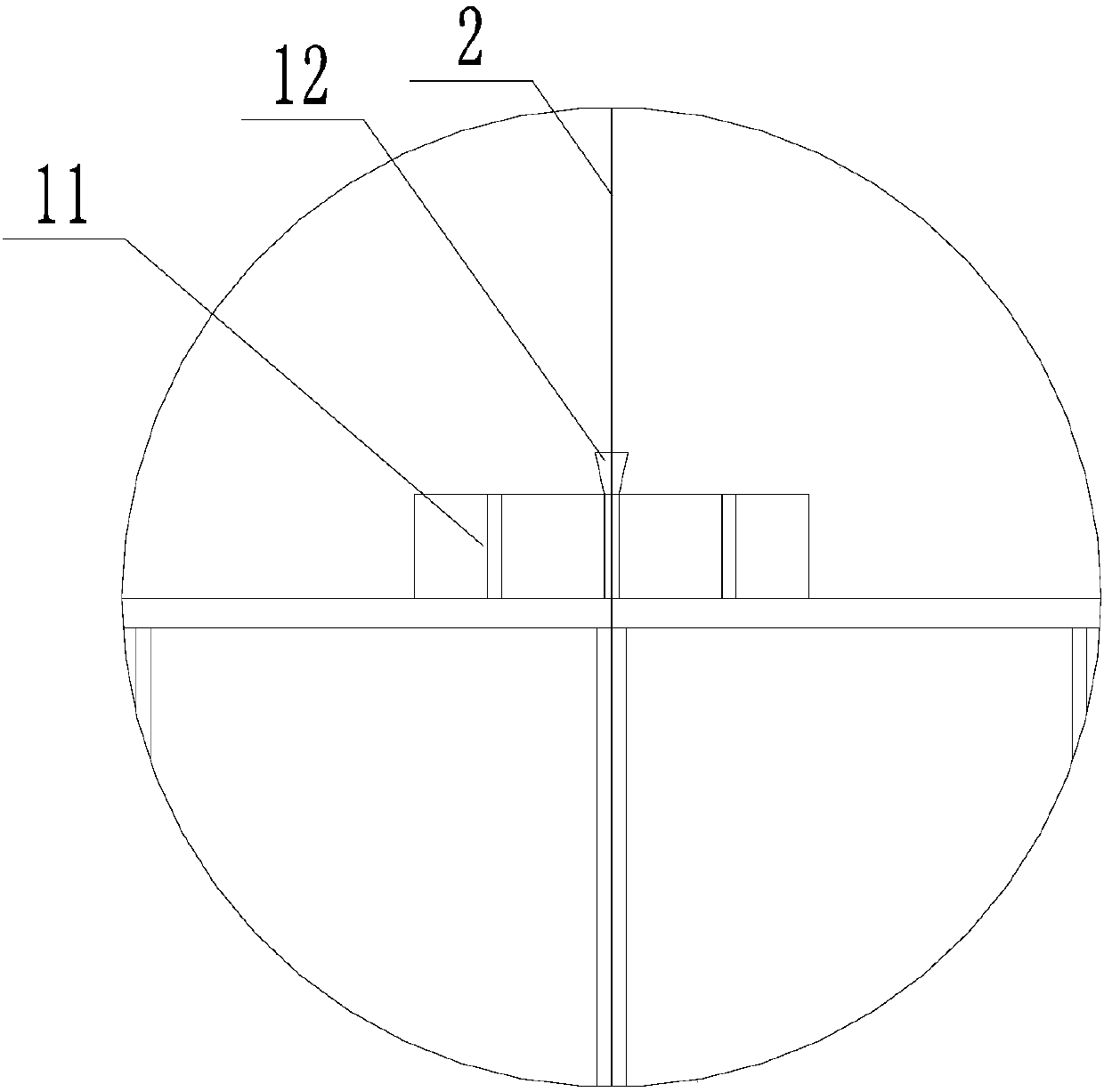

[0048] Such as figure 1 and Figure 10 A suspension system for the overall dismantling of the upward mobile formwork is shown, including two left and right symmetrical suspension systems installed on the upward mobile formwork; the upward mobile formwork is for the cast-in-place concrete beam The mobile formwork bridge building machine for construction, the upward mobile formwork includes two main girders 4 symmetrically arranged on the same horizontal plane, a formwork 22 for forming the cast-in-place concrete beam 21 and a support for the formwork 22 Formwork support frame, the two main beams 4 are arranged symmetrically above the left and right sides of the formwork 22;

[0049] The formwork support frame is hung on two main beams 4 by two symmetrically arranged suspender mechanisms, and each suspender mechanism includes a plurality of The suspension rods, a plurality of the suspension rods below the same main beam 4 are arranged on the same vertical plane;

[0050] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com