Shallow-buried bias tunnel asymmetric supporting structure and construction method

A support structure and asymmetric technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of environmental economic cost and time cost around the tunnel site area that cannot be ignored, difficult construction, long construction period, etc., to achieve Save economic cost and time cost, convenient construction and fast progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

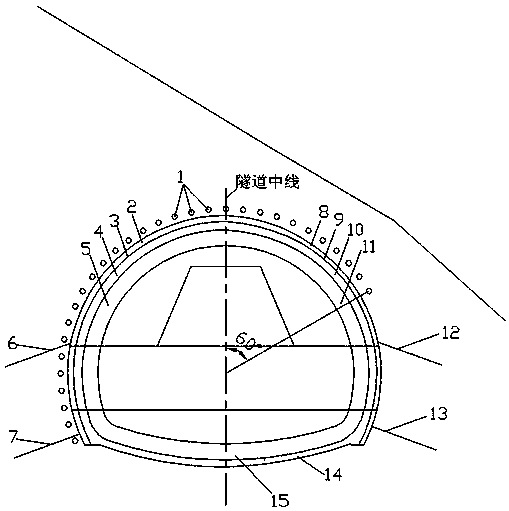

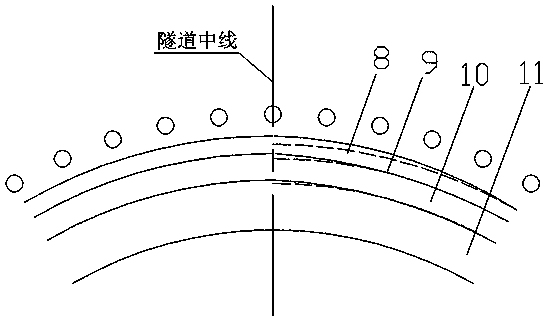

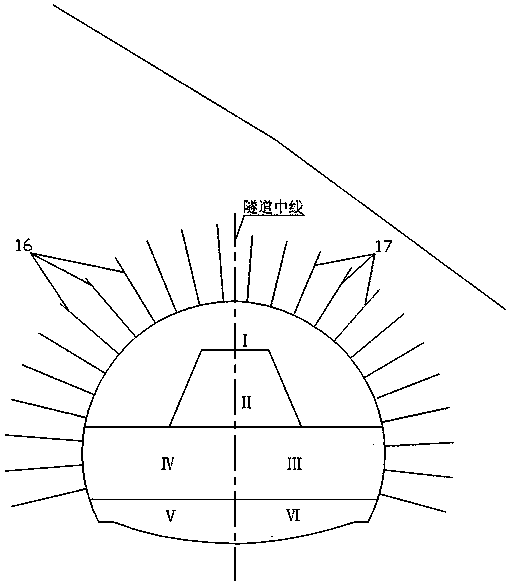

[0028] Such as figure 1 with figure 2 As shown, a shallow-buried unsymmetrical pressure tunnel asymmetric support structure system, including long pipe shed 1, deep-buried side primary sprayed concrete 2, deep-buried side steel arch 3, deep-buried side compound sprayed concrete 4, deep-buried side Secondary lining 5, deep-buried side upper step lock foot anchor rod 6, deep-buried side lower step lock foot anchor rod 7, shallow buried side primary sprayed concrete 8, shallow buried side steel arch 9, shallow buried side double sprayed concrete 10 , Shallow buried side secondary lining 11, shallow buried side upper step lock foot anchor 12, shallow buried side lower step lock foot anchor 13, invert initial support 14, invert 15, middle wall temporary support 16, waterproof Layer 18, deep-buried side system bolt 20 and shallow-buried side system bolt 21.

[0029] The deep-buried side primary sprayed concrete 2, deep-buried side steel arch 3, deep-buried side compound sprayed concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com