Asymmetric excavation construction organization method for super-large-section double-multi-arch tunnel

A super-large cross-section, double-arch technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of smooth transportation of materials and muck, achieve smooth transportation, increase the construction work surface, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

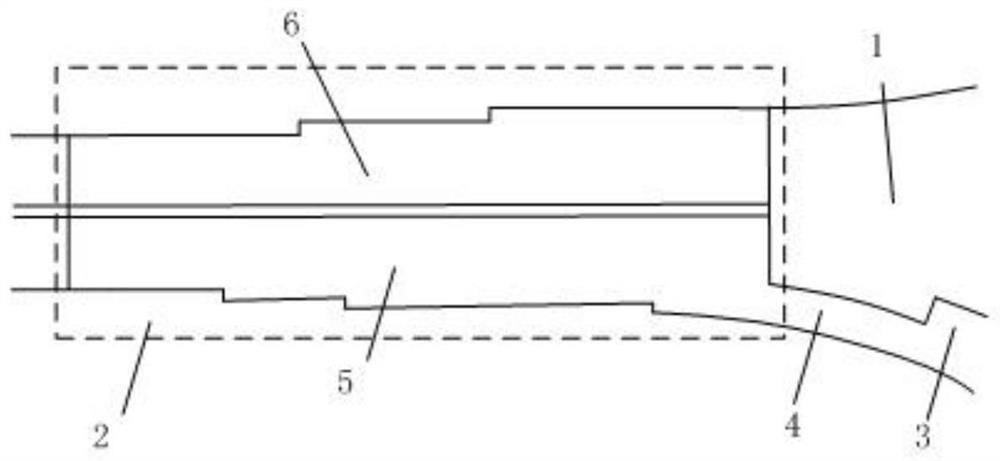

[0036] Such as Figure 1-4 As shown, an ultra-large section double-arch tunnel is asymmetric excavation construction tissue method, including the following steps:

[0037] Step 1: Excavation through the C-ramp 3 enters the border between the double-stranded tunnel segment 2 and the Mingzu section;

[0038] Step 2: Temporary channel 4 is opened by the step method 4, and the end of the tunnel to be opened;

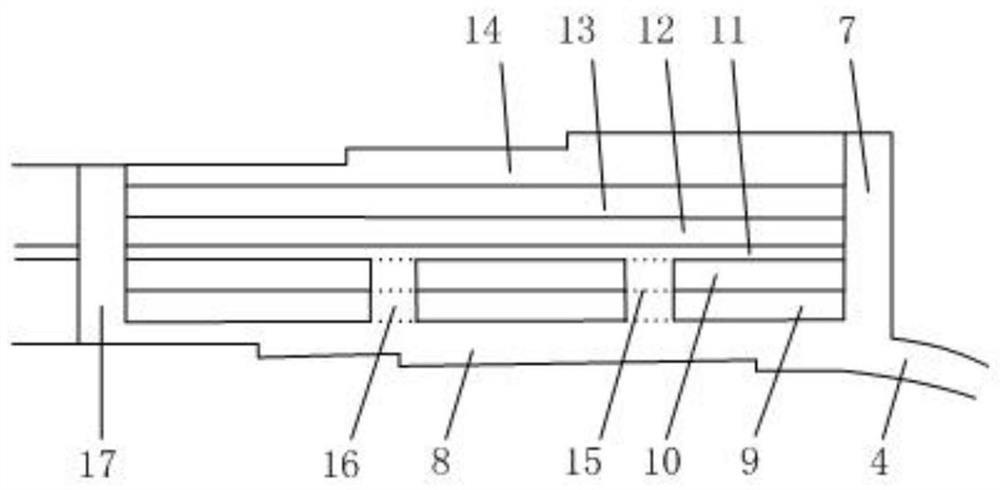

[0039] Step 3: During the 2 # cross channel 7, the step-by-step crossover 7 is opened, and the large line is applied to the hole in the right line of the double-louder tunnel.

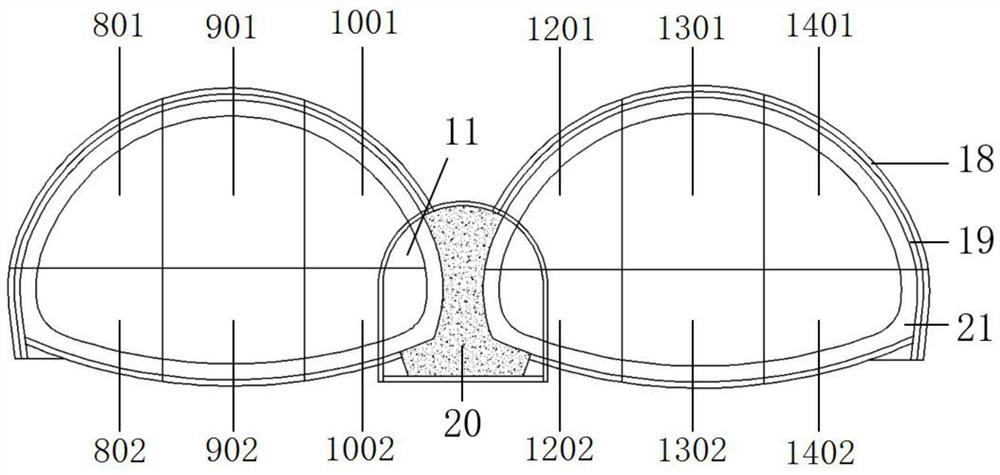

[0040] Step 4: After the double-connected arch right tunnel 5, after the upper tube is completed, the 1 # cave is 801, 2 # cave underwater hole 902 tunnel excavation and double support construction; 2 # cave The hole 901 excavated to 15m forming three steps, closed the palm of the palm;

[0041] Step 5: Excavation of the 2 # cross channel 7, forming a 0 # hole 11 construction excavation space, and excavat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com