Copper powder conveying mechanism and induction melting furnace thereof

A technology of feeding mechanism and copper powder, applied in furnaces, crucible furnaces, furnace components, etc., can solve the problems of reducing copper powder feeding efficiency, high-pressure fan damage, etc., and achieve the effect of simple mechanism, prolonging life and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

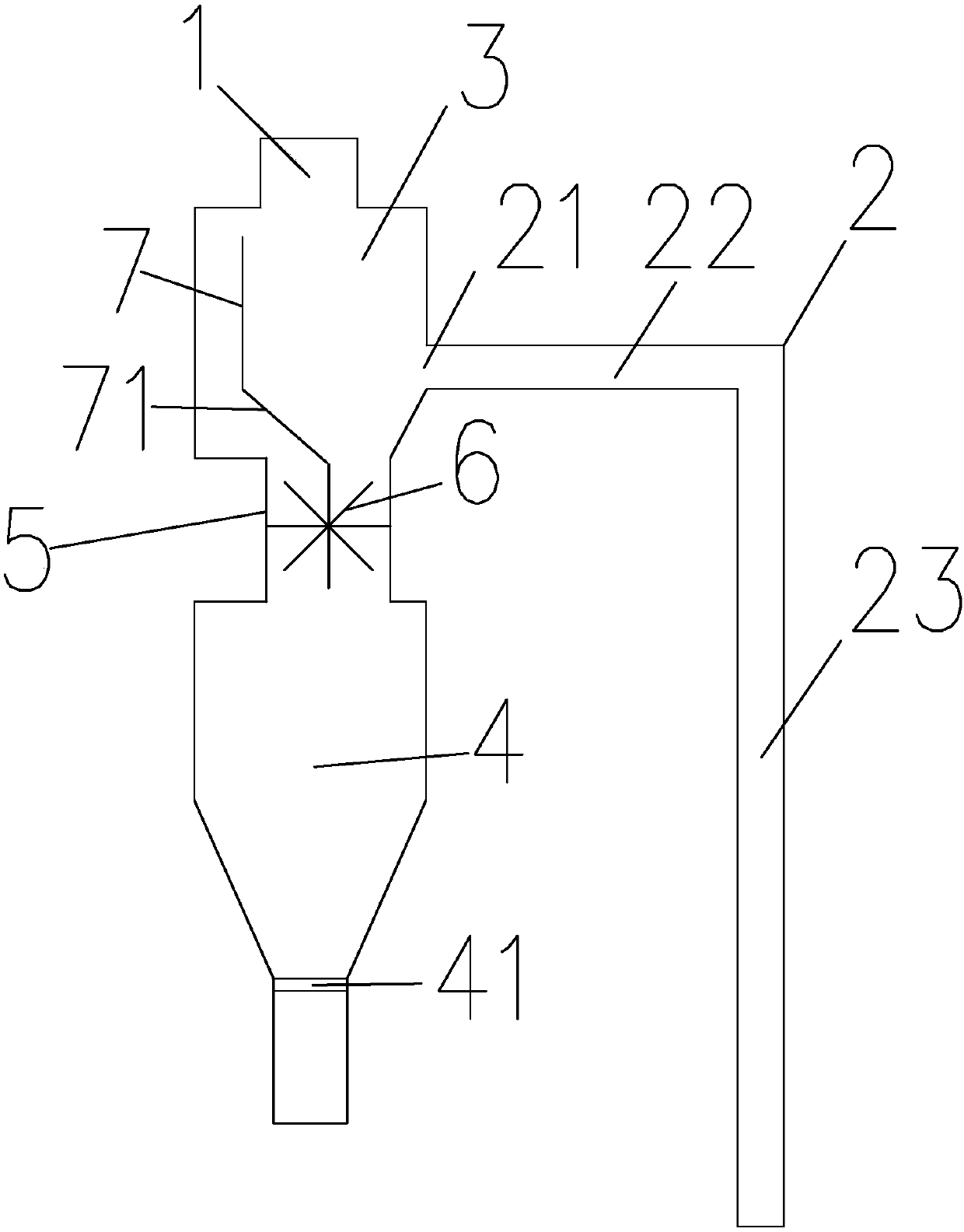

[0023] refer to figure 1 , a copper powder feeding mechanism of the present invention, comprising a high-pressure fan 1, a suction pipe 2, a separation chamber 3 and a storage bin 4, the storage bin 4 is a funnel shape, and the outlet at the lower end of the storage bin 4 Controlled by a solenoid valve 41. The separation chamber 3 communicates with the air inlet of the high-pressure fan 1 through an opening at the top, and a filter screen for filtering copper powder is set between the air inlet of the high-pressure fan 1 and the separation chamber 3 . The suction pipe 2 communicates with the separation chamber 3 through a suction port 21 arranged on the separation chamber 3, and the suction pipe 2 includes a horizontal pipe 22 connected to the feed port and is used to extract copper powder from the ground. The vertical pipe 23 that inhales copper powder in the collection box, the horizontal pipe 22 communicates with the vertical pipe 23, and the diameter of the suction pipe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com