Y-type joint pouring technology

A process and gate technology, applied in the field of Y-joint pouring process, can solve the problems of cracks, easy generation of pores and overheated sand, sand sticking, etc., to achieve uniform spraying, avoid bad results, and uniform and rapid heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

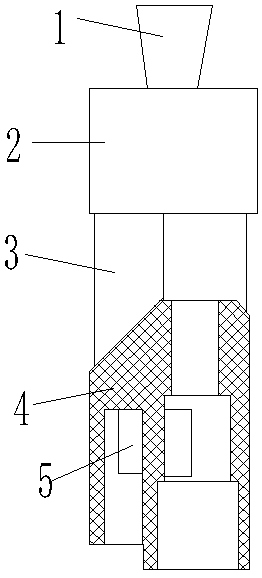

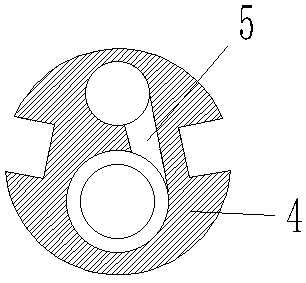

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0023] refer to Figure 1-2 , a Y-joint pouring process, comprising the following steps:

[0024] S1: According to the structure of the casting, set the feeding gate and riser at the main hot spot of the casting, so as to facilitate continuous locking during the cooling process;

[0025] S2: Vertical pouring is adopted, and the pressure formed by the self-weight of molten steel is used to ensure sufficient feeding capacity for the first cooling part;

[0026] S3: pouring is carried out in the order of cooling first for thin walls, replenishing for thicker walls, and replenishing cooling for risers at the end;

[0027] S4: Add an R angle to the bottom of the externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com