Bearing pad scraping device for large radial sliding journal bearings

A radial sliding, journal bearing technology, applied in the field of bearing pad scraping and grinding devices, can solve the problems of reducing scraping and grinding efficiency, affecting the normal operation of equipment, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

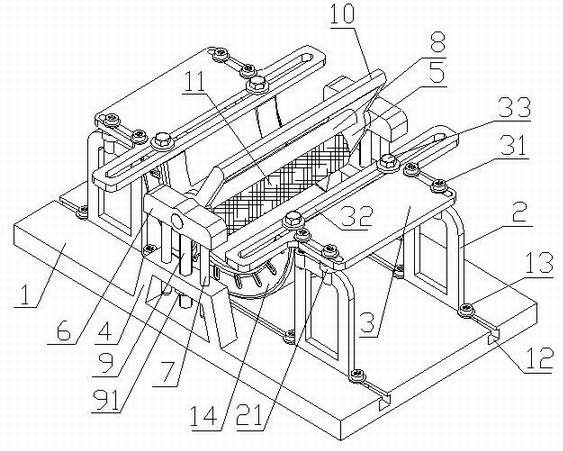

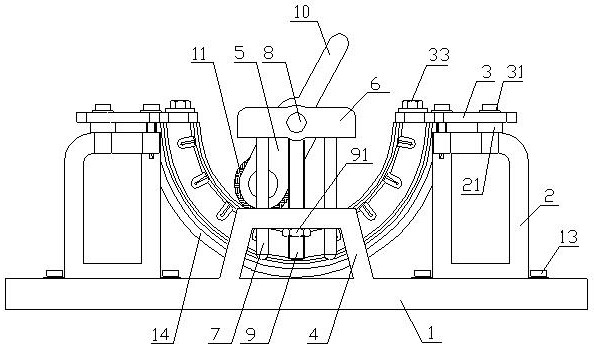

[0011] Example figure 1 and figure 2 As shown, the bearing pad scraping device of the large radial sliding journal bearing of the present invention includes a working platform 1, a pressing bracket 2, a pressing plate 3, a saddle bracket 4, a roller frame 5, a lifting block 6, a guide rod 7, and a rotating shaft 8. Screw 9, rolling handle 10 and tile surface grooving roller 11, the surface of the working platform 1 is provided with chute 12 at intervals, the pressing bracket 2 is located at both ends of the working platform 1, and the bottom is located on the In the chute 12, it is positioned by the locking screw 13, the pressing plate 3 is set on the top surface of the pressing bracket 2 through the bolt 31 and the inner side is provided with a long groove 32, and the saddle bracket 4 is arranged on the The two sides of the middle part of the working platform 1 and the top surface are spaced with through holes, the guide rod 7 and the screw rod 9 are arranged at intervals o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com