Airfoil-shaped body having composite base skin with integral hat-shaped spar

An airfoil and skin technology, applied in the field of airfoils, can solve problems such as reducing the stall speed of the aircraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

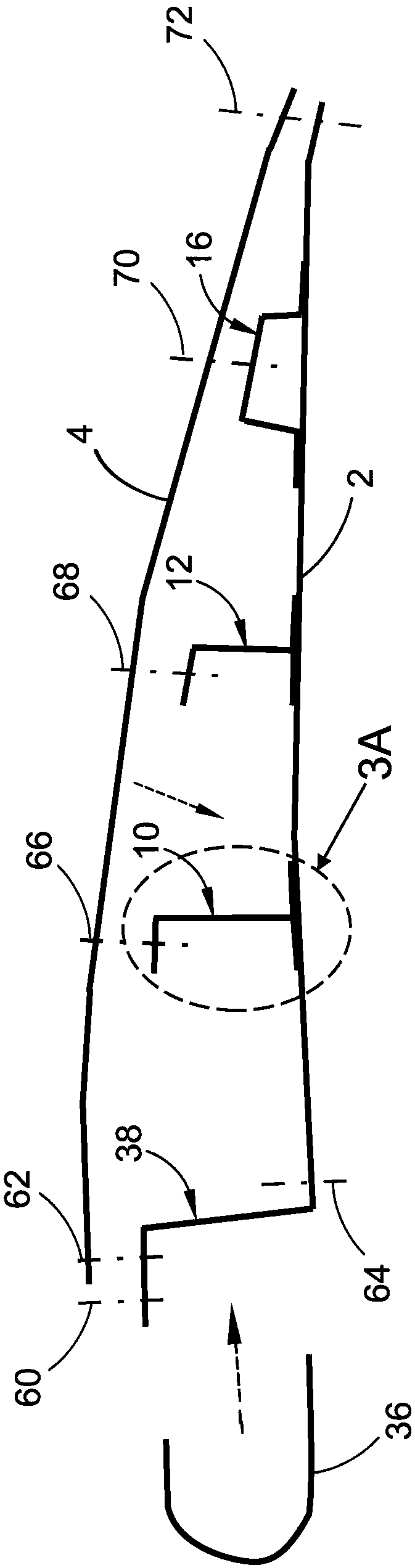

[0065]According to one embodiment, the manufacturing method comprises the steps of: placing a first plurality of fabric layers onto a surface of a base tool having recesses configured to shape a hat spar; placing a core on top of the first plurality of fabric layers placing the shaft into the recess; placing the two fills and the second plurality of fabric layers over the mandrel and adjacent portions of the first plurality of fabric layers; placing the baffle over the second plurality of fabric layers; Placing a vacuum bag over the baffle; evacuating a space between the vacuum bag and the base tool; infusing resin into the first plurality of fabric layers and the second plurality of fabric layers; and curing the infused resin.

[0066] According to one embodiment, a manufacturing method comprises the steps of: placing a plurality of braids onto a surface of a base tool having a recess configured to form a hat spar; placing a mandrel on top of the plurality of braids in the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com