Novel sewage precipitation and purification device

A new type of sewage technology, applied in sedimentation treatment, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of poor applicability, cumbersome operation, complex structure of alum crushing equipment, etc., and achieve the effect of improving crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

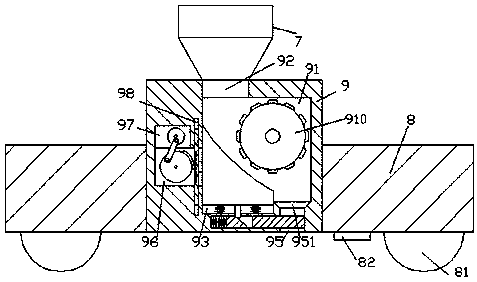

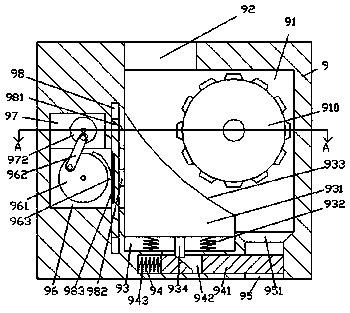

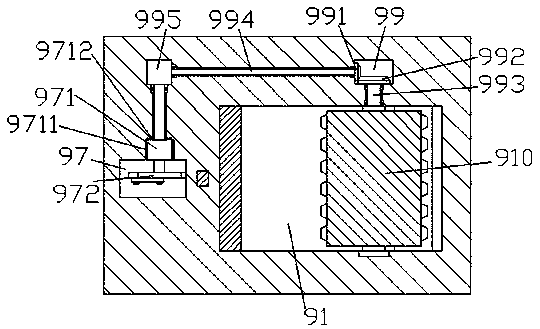

[0019] Such as Figure 1-Figure 5 As shown, a new type of sewage sedimentation and purification device of the present invention includes a base 8 and a main body 9 installed in the base 8. The main body 9 is provided with a crushing cavity 91, and the crushing inner The inner top wall on the right side of the cavity 91 is penetrated with a port 92. The top surface of the main body 9 above the port 92 is fixedly provided with a cone-shaped bucket 7. A sliding guide cavity 93 is provided. The inner bottom wall of the crushing cavity 91 on the right side of the sliding guide cavity 93 is provided with a discharge port 95 penetrating through it. The top of the discharge port 95 is provided with a tapered groove 951, The sliding sliding cavity 93 is smoothly connected with an upwardly extending lifting slider 931, and the top extension of the lifting sliding slider 931 reaches into the crushing cavity 91 and into the crushing cavity. The top of the lifting slider 931 in 91 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com