A high-efficiency alum feeding device for purifying sewage

A sewage and alum technology, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as high labor intensity, inability to adjust according to actual needs, and slow delivery speed, and achieve The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

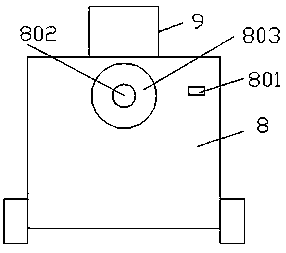

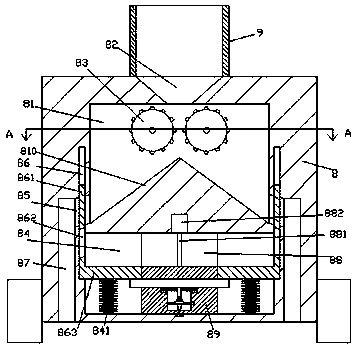

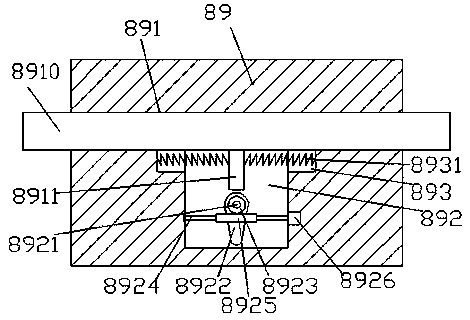

[0021] like Figure 1-Figure 9 As shown, a kind of high-efficiency alum throwing equipment for purifying sewage of the present invention includes a main body 8 and an addition box 9 installed on the top of the main body 8, and the inner wall of the main body 8 is provided with a crushing chamber 81, The inner top wall of the crushing chamber 81 is provided with a connecting chamber 82 connected to the bottom of the adding box 9 , and the left and right sides of the crushing chamber 81 below the bottom of the connecting chamber 82 are equally arranged. There is a rotary crushing device 83, a guide slide 810 is fixedly arranged on the inner bottom wall of the crushing chamber 81 below the rotary crushing device 83, and a second A sliding chamber 84, the inner wall of the first sliding chamber 84 is provided with a guiding chamber 88, and the main body 8 on the left and right sides of the first sliding chamber 84 is provided with a delivery channel 87 extending up and down. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com