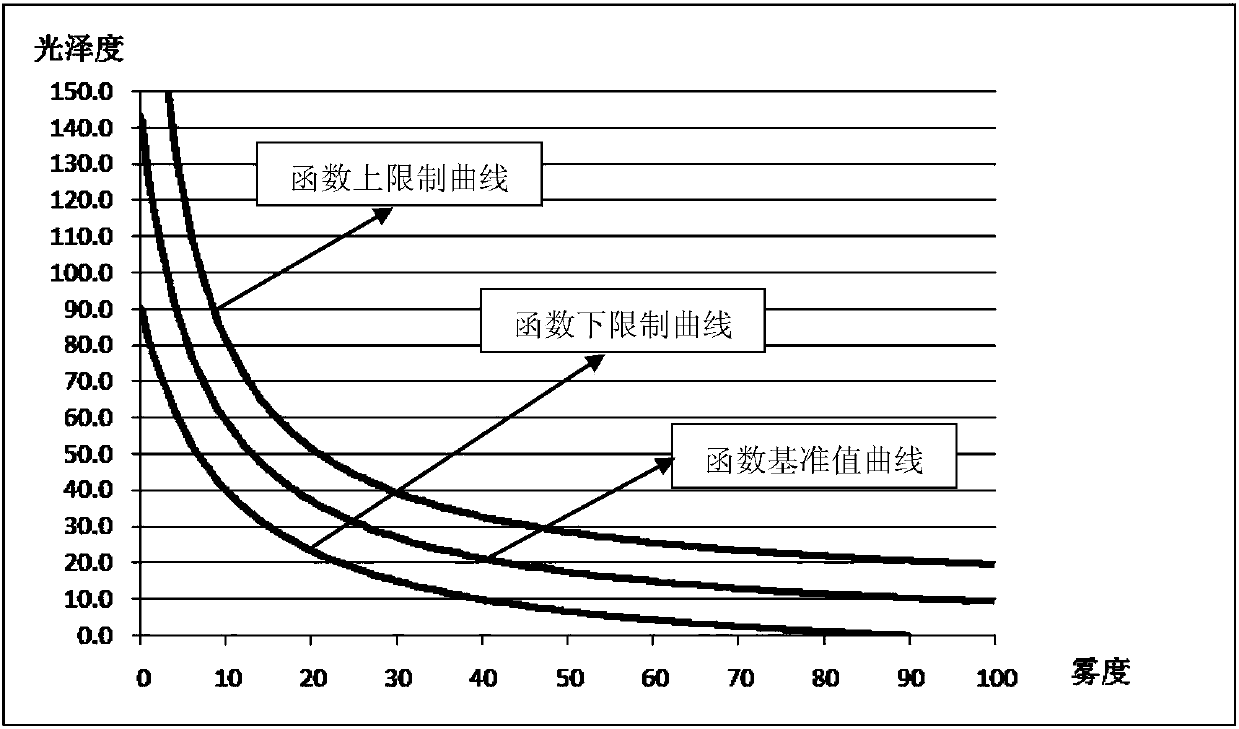

Optical glass satisfying Clapeyron-like functional relationship and preparation method thereof

A technology of optical glass and functional relationship, which is applied in the direction of optical surface grinder, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of flash point, low definition, high gloss, etc., and achieve low preparation cost, light weight, Easy operation and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a plurality of pieces of optical glass, such as figure 2 As shown, each piece of said optical glass has only one said low gloss surface.

[0055] In order to better illustrate the specific implementation methods provided in this example, it is necessary to first introduce the testing instruments, testing principles and calculation methods used in testing the average roughness, haze and gloss in this example.

[0056] 1) Detection of the average roughness of the low-gloss surface

[0057] Testing instrument: SJ-210 Surface Average Roughness Measuring Instrument.

[0058] Test principle: When the stylus is directly across the measured surface of the workpiece, due to the peak and valley fluctuations of the measured surface profile, the stylus will move back and forth in the direction of the measured surface, so that this movement can be transmitted to the signal through the electronic device. Zoom in, and then output data and images about the a...

Embodiment 2

[0108] The optical glass provided in this embodiment has two above-mentioned low-gloss surfaces facing up and down. The average roughness and gloss of the two low-gloss surfaces and the haze of the optical glass were detected respectively according to a method mentioned in the embodiment.

[0109] It should be pointed out that gloss and average roughness are concepts for reflecting light on a single surface, while haze is a concept for penetrating light. Therefore, for optical glass with two opposite low-gloss surfaces, The Clapeyron-like function relationship it satisfies is:

[0110] in,

[0111] X is haze, the unit is "degree",

[0112] Y is the average roughness, the unit is "nm",

[0113] Z is glossiness, the unit is "degree",

[0114] K is a constant value of 10,

[0115] ε is a coefficient with a value of 0.5.

[0116] Through detection and calculation, the average roughness value of the upper and lower low-gloss surfaces is 316, the gloss value of the upper and ...

Embodiment 3

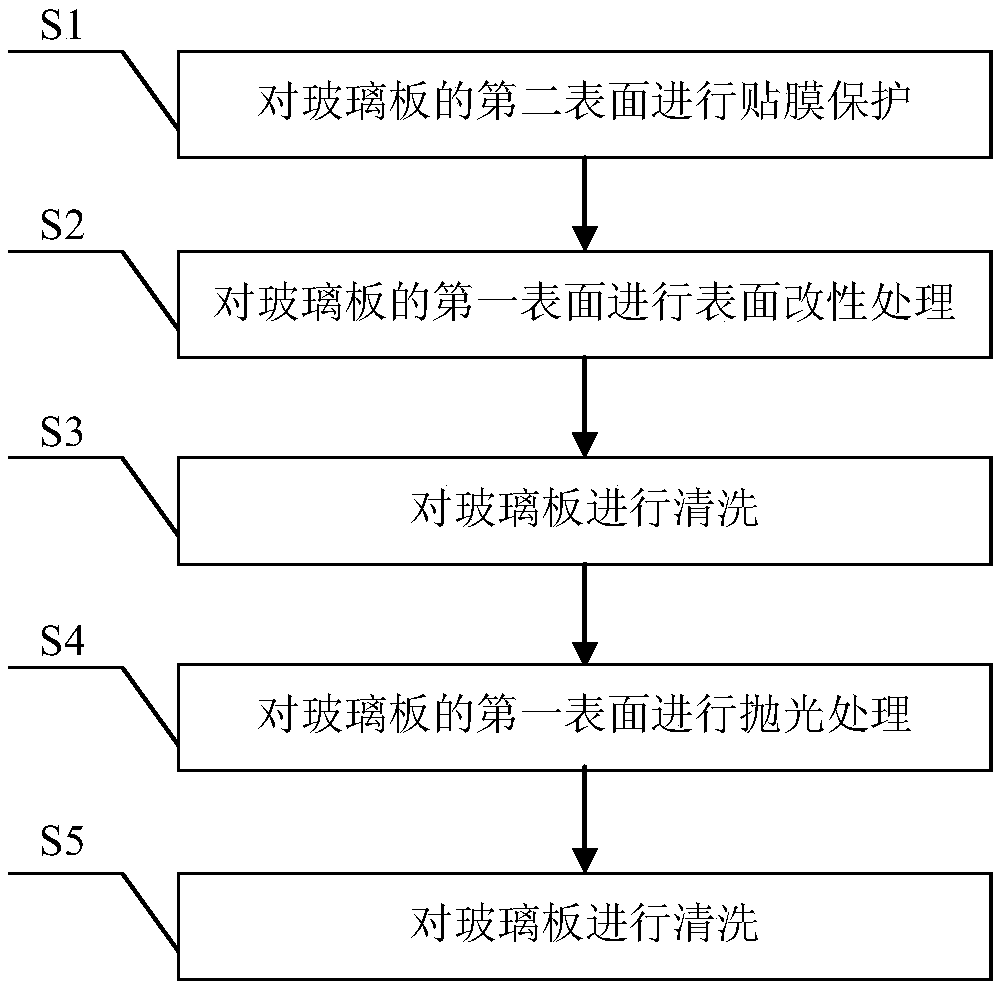

[0120] This embodiment provides a method for preparing optical glass, which is used to prepare a glass plate with opposite first and second surfaces to be processed into optical glass with a low-gloss surface as described in Embodiment 1, see Figure 4 , the preparation method comprises the following steps:

[0121] Step S1, protecting the second surface of the glass plate with a film.

[0122] Specifically, a corrosion-resistant plastic protective film is pasted on the second surface and four sides of the glass plate by using a laminator, the thickness of the protective film is 0.1±0.05mm, and within this range, the protective film It can effectively protect other surfaces of the glass display screen without significantly affecting the size of the glass display screen, facilitating its processing and moving. The function of the protective film is to protect other surfaces from corrosion and improve the quality of the product.

[0123] It should be noted that, in other embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com