Optical path debugging device for a fiber-optic gyroscope

A fiber optic gyroscope and optical path technology, applied in measuring devices, instruments, etc., can solve the problems of low automation, low efficiency, inability to meet large batches, and precision requirements in the production environment of fiber optic gyroscopes, and achieve the effect of improving product engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

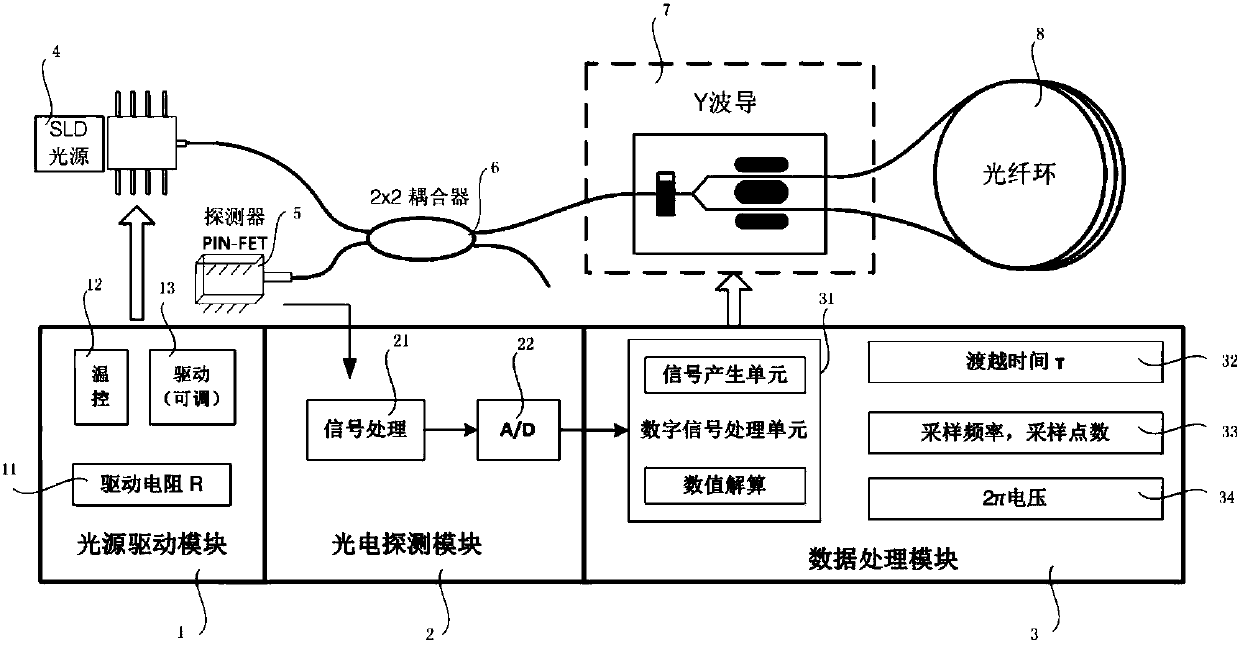

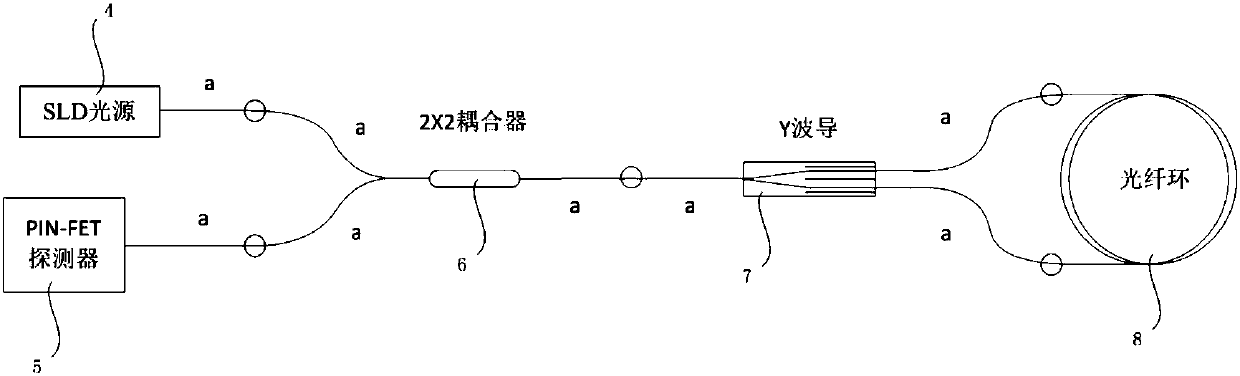

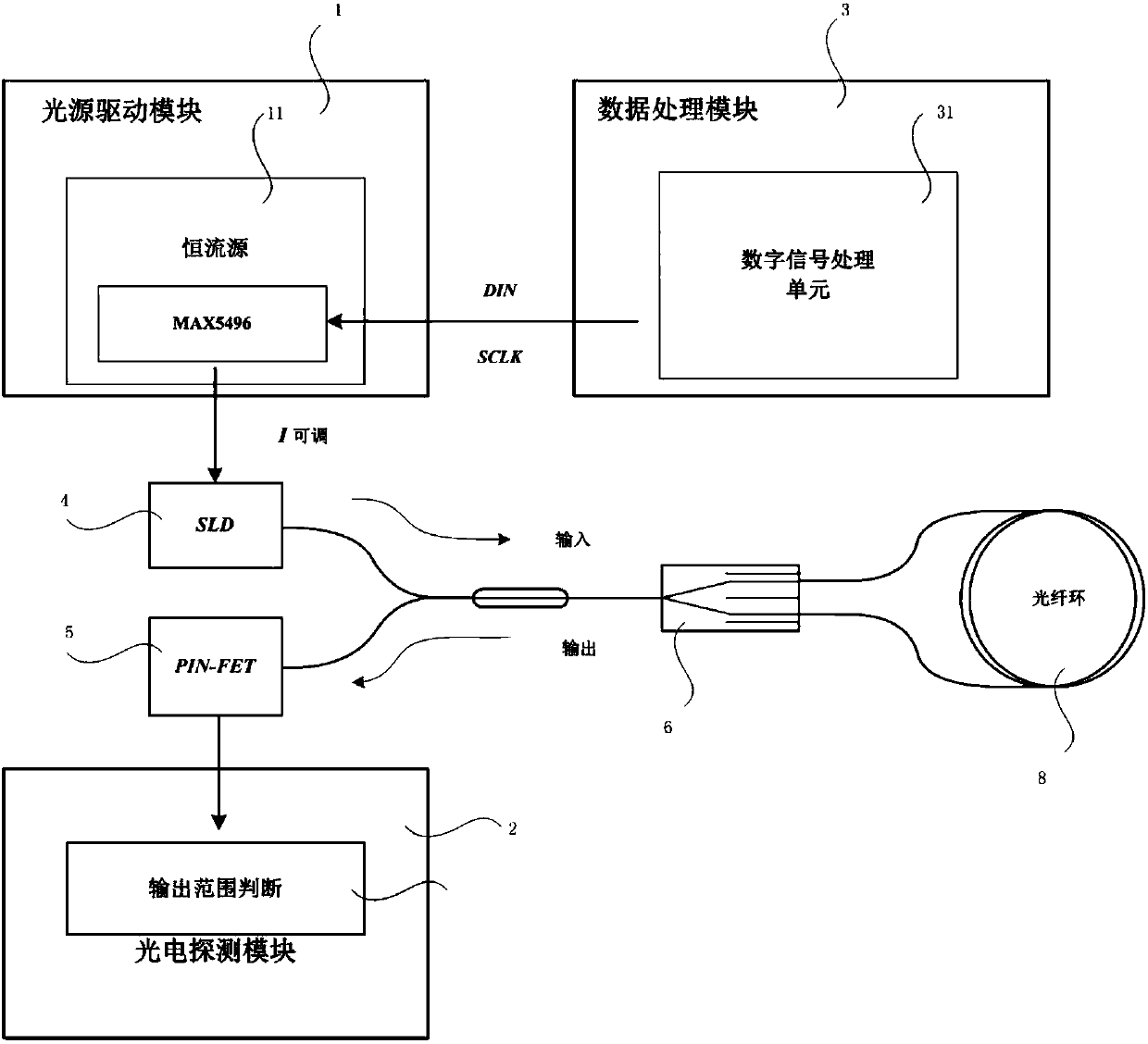

[0022] figure 1 Shown is the block diagram of the optical path debugging equipment used in the present invention for fiber optic gyroscope, as figure 1 As shown, the optical path debugging equipment for the fiber optic gyroscope includes: a light source driving module 1 , a photoelectric detection module 2 and a data processing module 3 . The light source driver module 1 provides the temperature control and drive required by the SLD light source 4. Through the change of the adjustable resistance value, the output power of the light source is changed to provide the required fiber output power for the entire optical path; the photoelectric detection module 2 is a PIN-FET detection The power supply of the detector 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com