Vibrating wire type water level indicator with self-compensation function

An automatic compensation, vibrating wire technology, applied in the direction of buoy liquid level indicator, etc., to achieve the effect of reliable waterproof sealing, strong survivability, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Example 1:

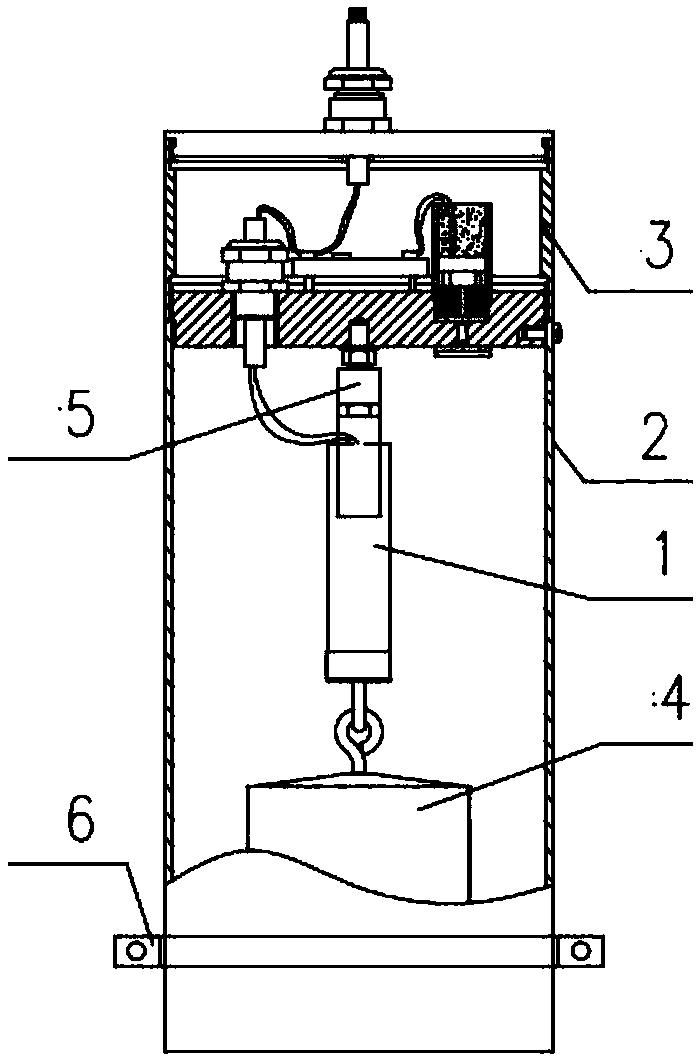

[0035] This embodiment is a high-precision vibrating wire water level gauge with automatic compensation, and its main structure is as follows image 3 Shown.

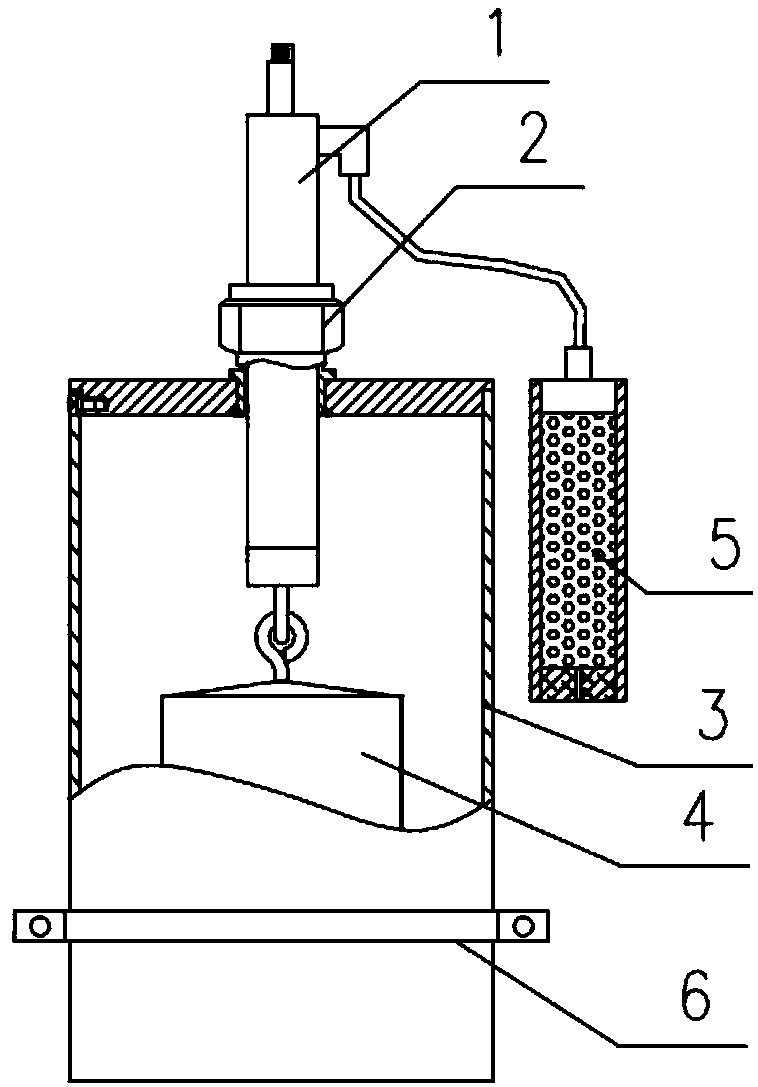

[0036] Reference image 3 , The high-precision vibrating wire water level gauge with automatic compensation in this embodiment is mainly composed of sensitive parts 1, protective cylinder 2, intelligent compensation output parts 3, float parts 4, sensitive parts mounting and fixing parts 5 and instrument integral mounting and fixing parts 6 composition. The sensitive component 1 is freely hung inside the protective cylinder 2 through the universal joint of the sensitive component mounting and fixing component 5, and the intelligent compensation output component 3 is located on the upper part of the protective cylinder 2 and fixed with it. The float component 4 is connected to the sensitive The components 1 are connected together and hung inside the protective cylinder 2. The integral installation and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com