Cooling module and brush motor thereof

A brushed motor and winding technology, applied in windings, electromechanical devices, electrical components, etc., can solve the problems of reduced production efficiency, large total number of winding turns, long winding time, etc., to improve production efficiency and reduce the total number of turns. , The effect of shortening the winding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

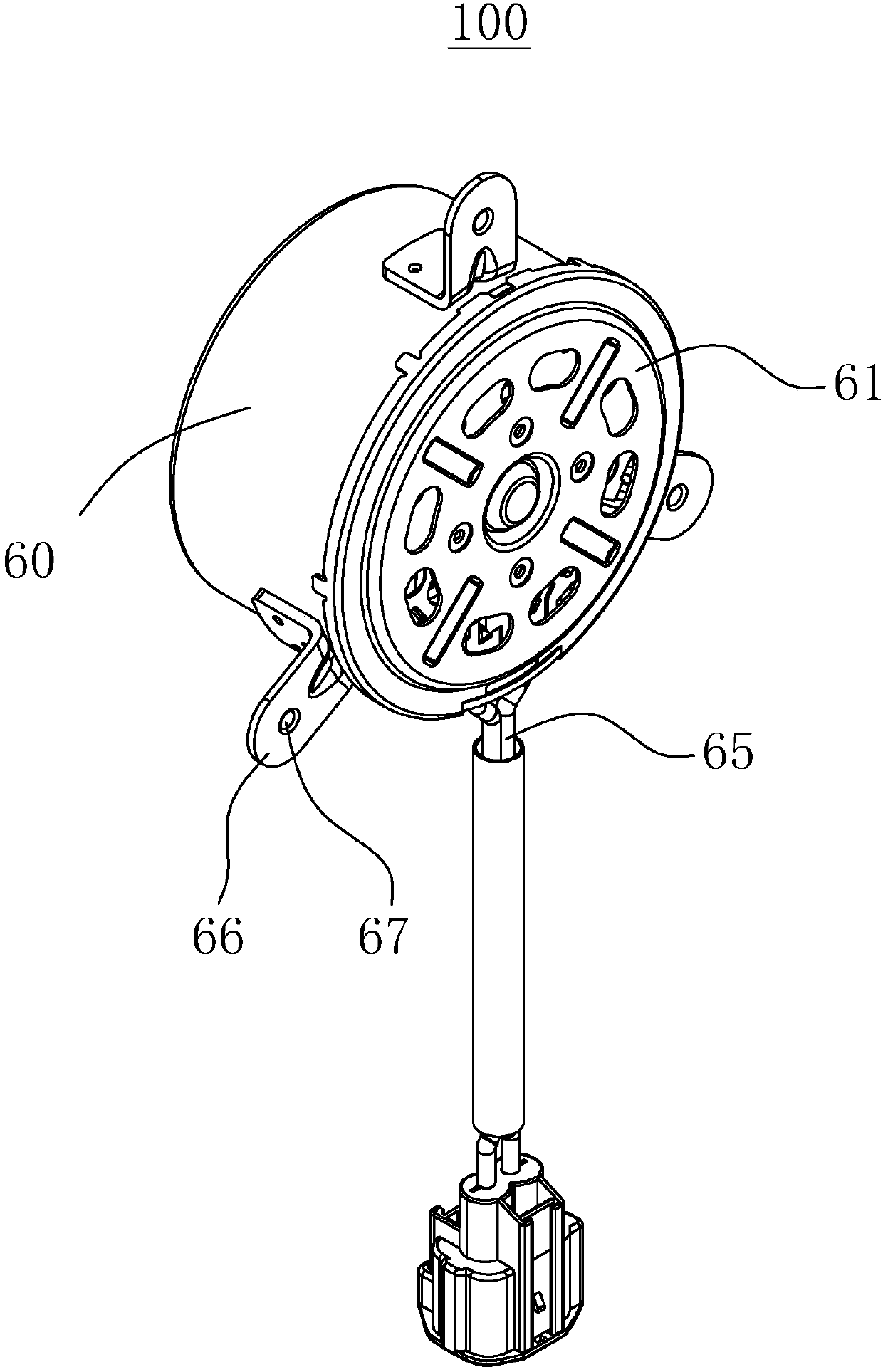

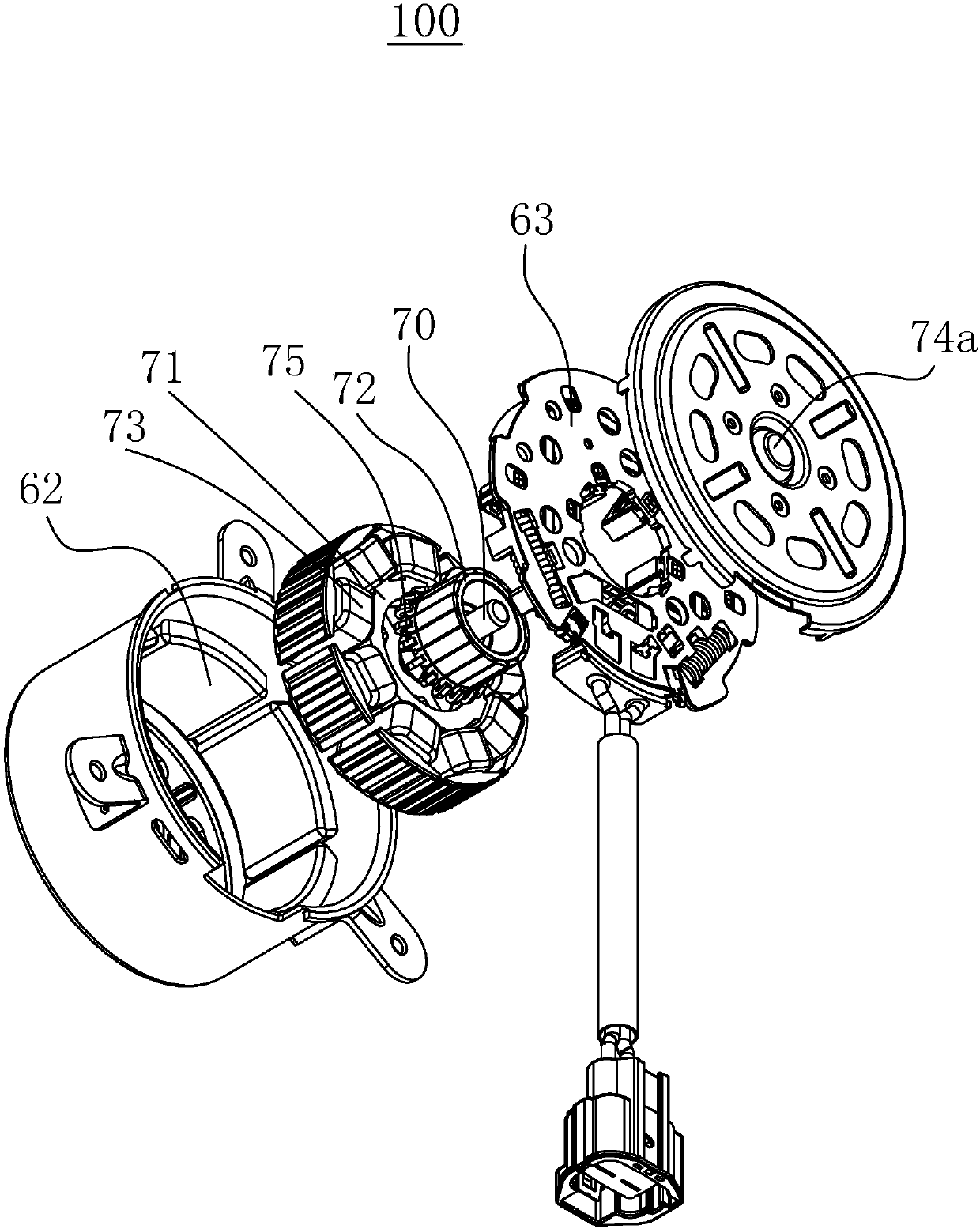

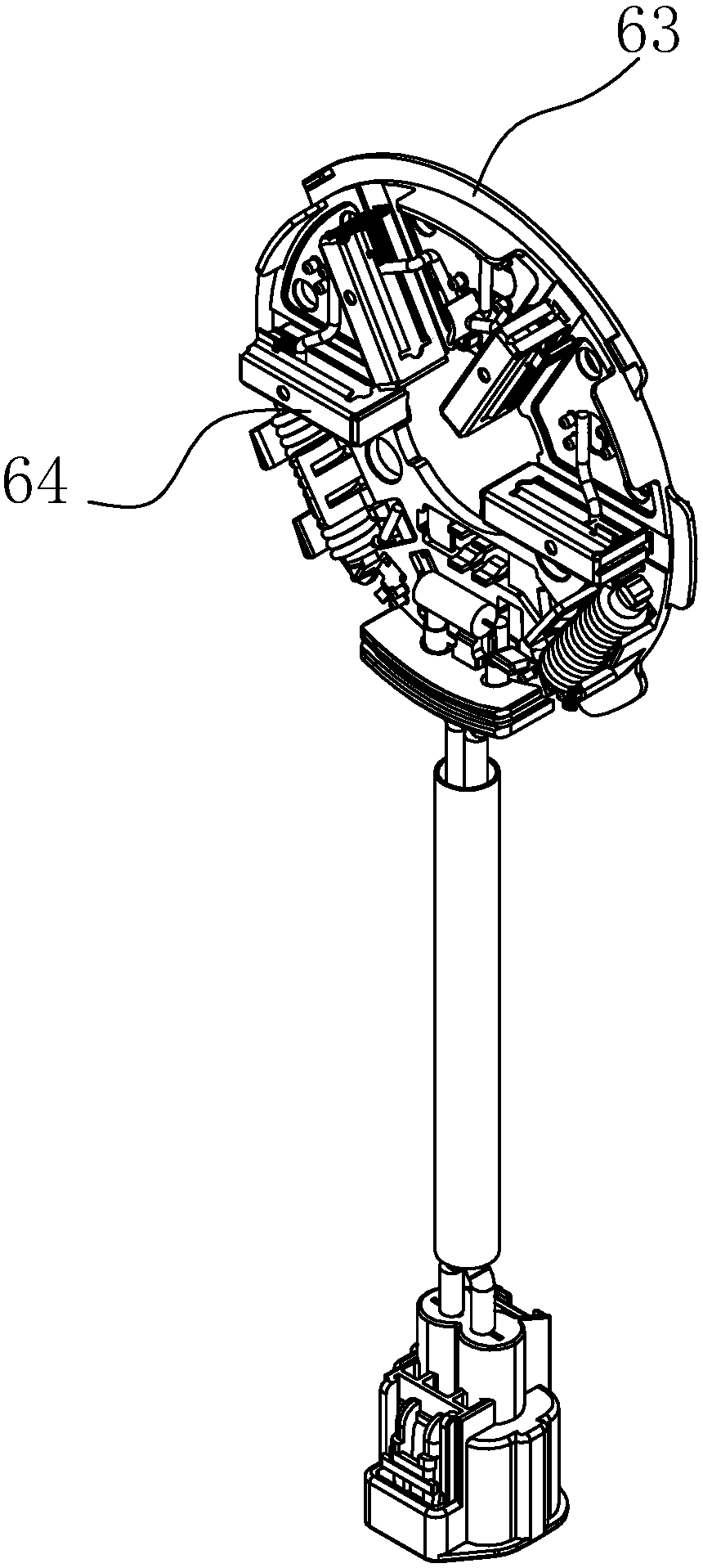

[0029] refer to figure 1 , figure 2 and image 3 , The brushed motor 100 provided by the embodiment of the present invention is a DC brushed motor, including a stator and a rotor. The stator includes a housing 60 , a permanent magnet 62 mounted to the inner wall of the housing 60 , and an end cover 61 fixed to the open end of the housing 60 . The permanent magnets 62 form six stator poles of the stator. If P is used to represent the number of stator pole pairs, then P is three. An L-shaped connecting part 66 is mounted on the outer wall of the housing 60 , and the L-shaped connecting part 66 has a through hole 67 for fasteners to pass through to install the brushed motor 100 . A brush holder 63 is installed on the end cover 61 , and a brush 64 is installed on the brush holder 63 .

[0030] The rotor includes a rotating shaft 70 , a rotor core 71 coaxially fixed to the rotating shaft 70 , and a commutator 72 . The rotor is installed in the housing 60, and the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com