Steamed dumpling moulding equipment

A molding equipment, a technology for burning wheat, which is applied to the machinery or equipment for dough molding, dough processing, baking, etc., can solve problems such as inability to meet, and achieve the effects of improving production efficiency, ensuring integrity, and facilitating disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

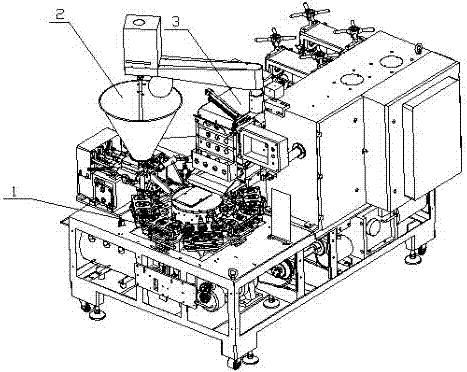

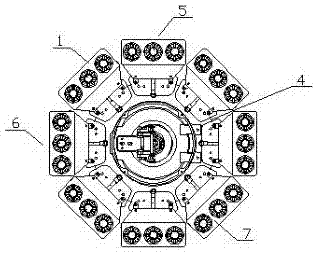

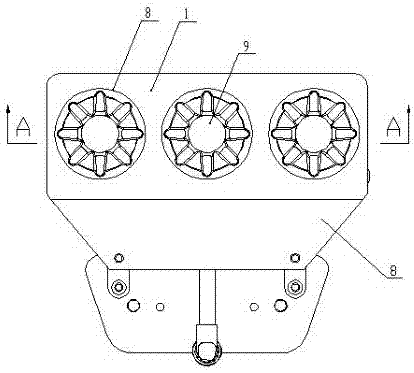

[0031] Such as Figures 1 to 5 As shown, the siu mai forming equipment includes a frame and an annular track 4 arranged on the frame, and the annular track 4 is successively provided with a skin grafting station 5, a stuffing station 6 and a material pushing station 7. Dough conveying device 3 is provided at the 5 places of the skin-joining station, a stuffing device 2 is provided at the 6 places of the filling filling station, and a skin-receiving plate 1 that can move around the circular track 4 is provided on the circular track 4 , the skin-connecting plate 1 is provided with a forming groove 8, the forming groove 8 is provided with a through hole 9, the bottom of the skin-connecting plate 1 is provided with a telescopic rod 11, and the telescopic end of the telescopic rod 11 A connecting plate 12 is fixed, and the bottom end of the lifting body 10 is connected to the connecting plate 12 , and the top end of the lifting body 10 is movably arranged in the through hole 9 .

...

Embodiment 2

[0040] Such as Figures 1 to 5 As shown, the siu mai forming equipment includes a frame and an annular track 4 arranged on the frame, and the annular track 4 is successively provided with a skin grafting station 5, a stuffing station 6 and a material pushing station 7. Dough conveying device 3 is provided at the 5 places of the skin-joining station, a stuffing device 2 is provided at the 6 places of the filling filling station, and a skin-receiving plate 1 that can move around the circular track 4 is provided on the circular track 4 , the skin-connecting plate 1 is provided with a forming groove 8, the forming groove 8 is provided with a through hole 9, the bottom of the skin-connecting plate 1 is provided with a telescopic rod 11, and the telescopic end of the telescopic rod 11 A connecting plate 12 is fixed, and the bottom end of the lifting body 10 is connected to the connecting plate 12 , and the top end of the lifting body 10 is movably arranged in the through hole 9 .

...

Embodiment 3

[0047] Such as Figures 1 to 5 As shown, the siu mai forming equipment includes a frame and an annular track 4 arranged on the frame, and the annular track 4 is successively provided with a skin grafting station 5, a stuffing station 6 and a material pushing station 7. Dough conveying device 3 is provided at the 5 places of the skin-joining station, a stuffing device 2 is provided at the 6 places of the filling filling station, and a skin-receiving plate 1 that can move around the circular track 4 is provided on the circular track 4 , the skin-connecting plate 1 is provided with a forming groove 8, the forming groove 8 is provided with a through hole 9, the bottom of the skin-connecting plate 1 is provided with a telescopic rod 11, and the telescopic end of the telescopic rod 11 A connecting plate 12 is fixed, and the bottom end of the lifting body 10 is connected to the connecting plate 12 , and the top end of the lifting body 10 is movably arranged in the through hole 9 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com