Outer packaging case for power storage equipment and method of manufacturing the same

A technology for electrical storage equipment and outer packaging, applied in the field of capacitors and batteries, can solve the problems of insufficient adhesive tape adhesion and easy peeling of adhesive tapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

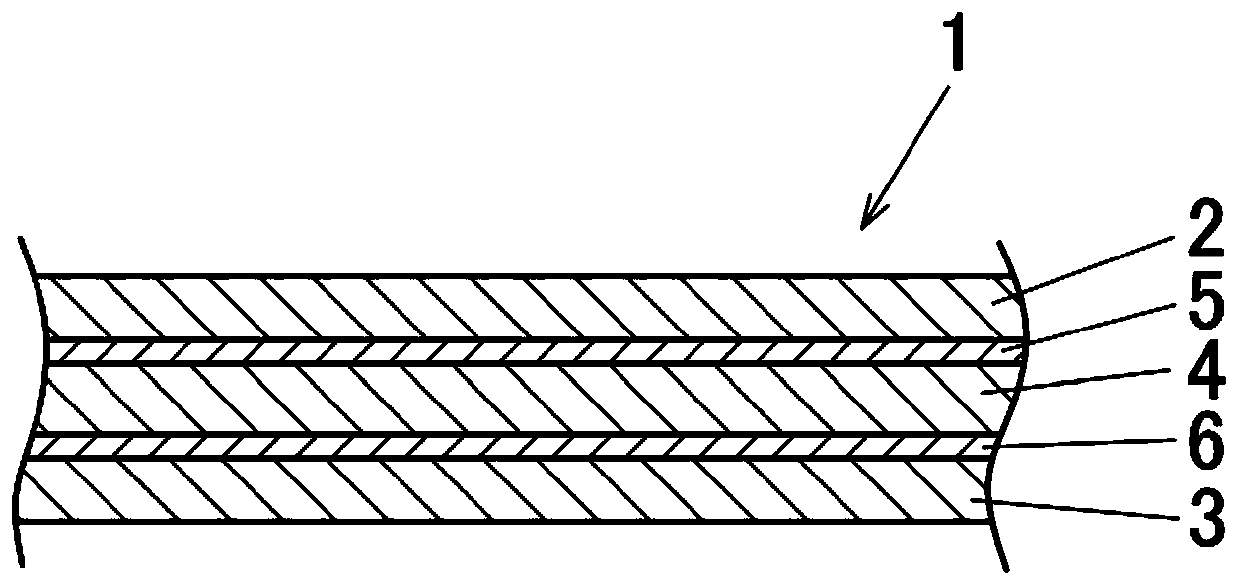

[0089] A chemical conversion treatment liquid containing phosphoric acid, polyacrylic acid (acrylic resin), chromium (III) salt compound, water, and alcohol was coated on both sides of aluminum foil 4 with a thickness of 40 μm, and dried at 180° C. to form a chemical conversion film. The amount of chromium attached to this chemical conversion coating is 10mg / m per side 2 .

[0090] Next, a biaxially stretched nylon 6 film 2 with a thickness of 25 μm is dry-laminated (laminated) on one side of the aluminum foil 4 that has undergone the aforementioned chemical conversion treatment by means of a two-component curing polyurethane adhesive (2 μm in thickness) 5 . .

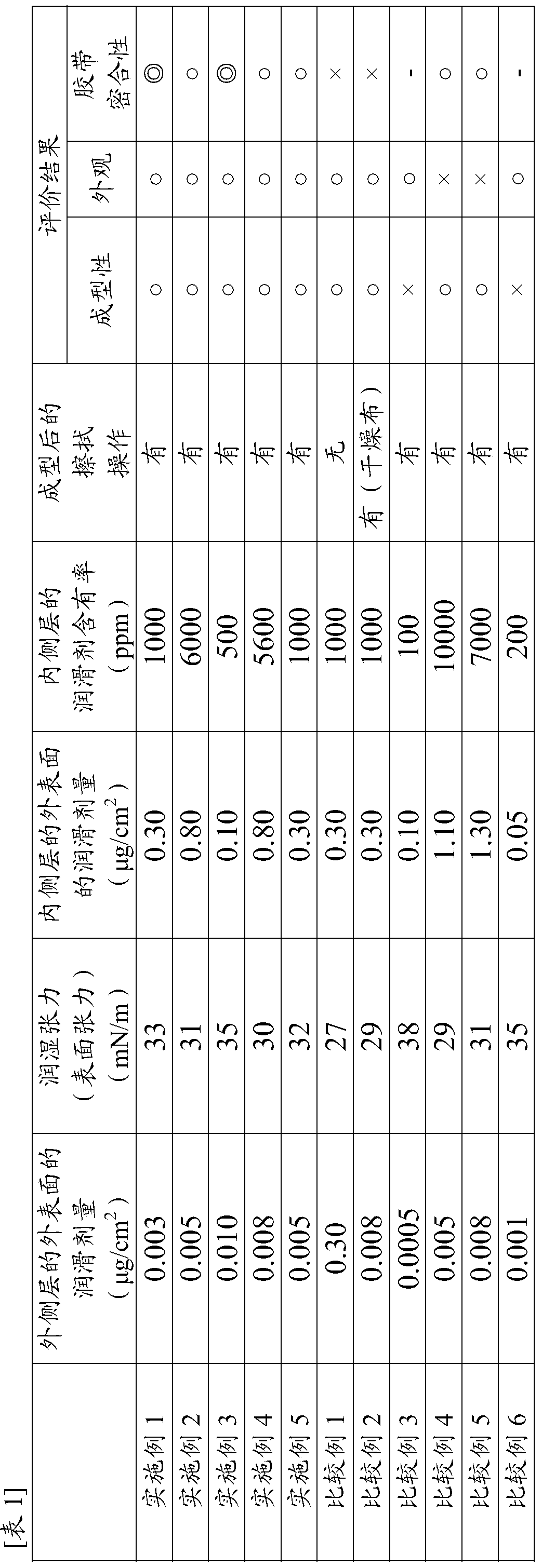

[0091] Next, a first non-stretched film with a thickness of 4.5 μm containing ethylene-propylene random copolymer, 1000 ppm of behenamide and 3000 ppm of silica particles (anti-blocking agent), containing ethylene-propylene block The second unstretched film with a thickness of 21 μm made of copolymer and 1000 ppm of ...

Embodiment 2

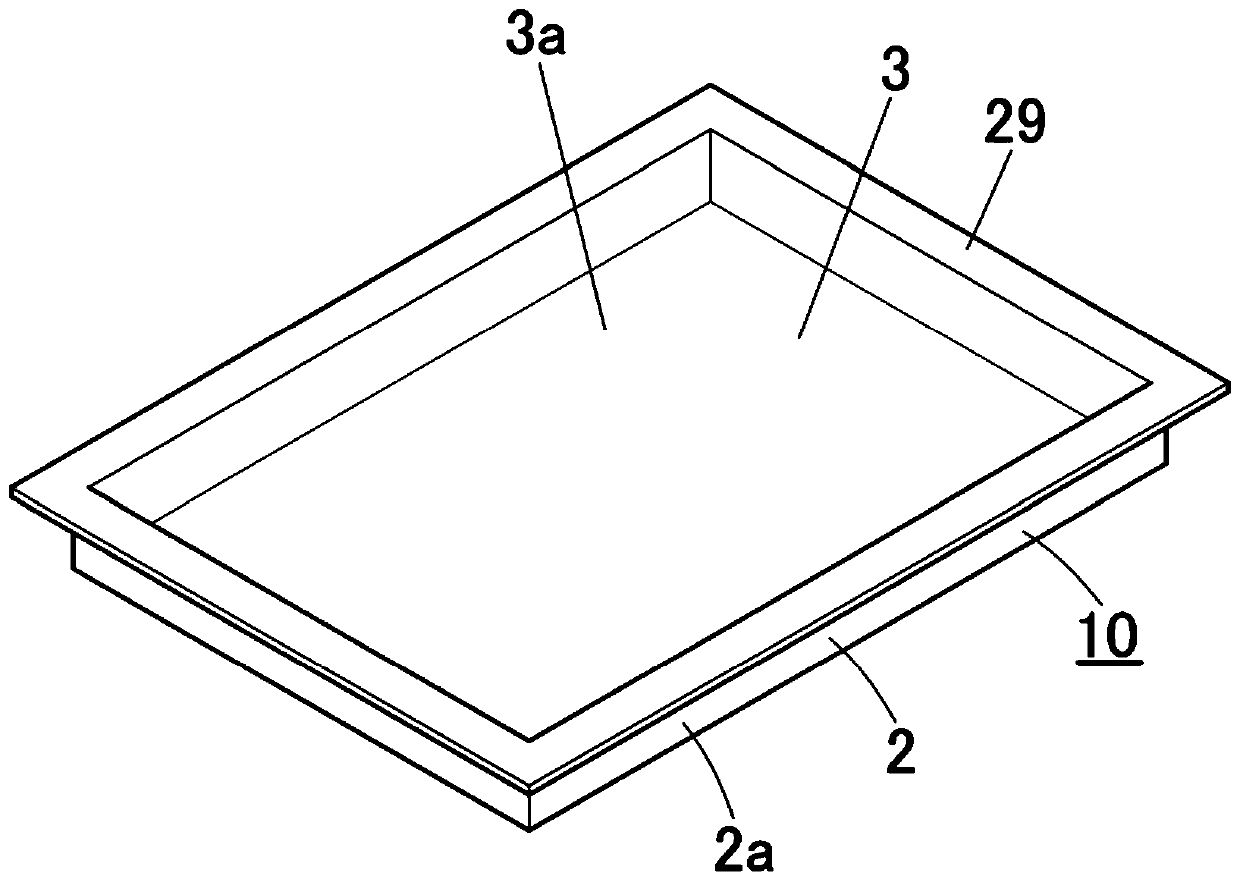

[0094] As the sealant film 3, a first unstretched film with a thickness of 4.5 μm containing ethylene-propylene random copolymer, 6000 ppm of behenamide and 3000 ppm of silica particles (anti-blocking agent) was used, containing ethylene -A second unstretched film with a thickness of 21 μm made of a propylene block copolymer and 6000 ppm of erucamide, and an ethylene-propylene random copolymer, 6000 ppm of behenamide and 3000 ppm of silica particles (anti-blocking The first non-stretched film with a thickness of 4.5 μm made of the agent) was co-extruded using a T-die by stacking three layers in this order, except that it was the same as in Example 1, and obtained figure 2 The illustrated outer casing 10 for an electrical storage device.

Embodiment 3

[0096] As the sealant film 3, a first unstretched film with a thickness of 4.5 μm containing ethylene-propylene random copolymer, 500 ppm of behenamide, and 3000 ppm of silica particles (anti-blocking agent) was used, containing ethylene -A second unstretched film with a thickness of 21 μm made of a propylene block copolymer and 500 ppm of erucamide, and containing ethylene-propylene random copolymer, 500 ppm of behenamide and 3000 ppm of silica particles (anti-blocking The first non-stretched film with a thickness of 4.5 μm made of the agent) was co-extruded using a T-die by stacking three layers in this order, except that it was the same as in Example 1, and obtained figure 2 The illustrated outer casing 10 for an electrical storage device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wetting tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com