Bracket bonding locator, manufacturing method thereof, and bracket positioning method

A locator and bracket technology, applied in the field of orthodontics, can solve the problems of inaccurate pasting position, out-of-sync acid etching, inconvenient operation, etc., and achieve the effects of convenient operation, time saving and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

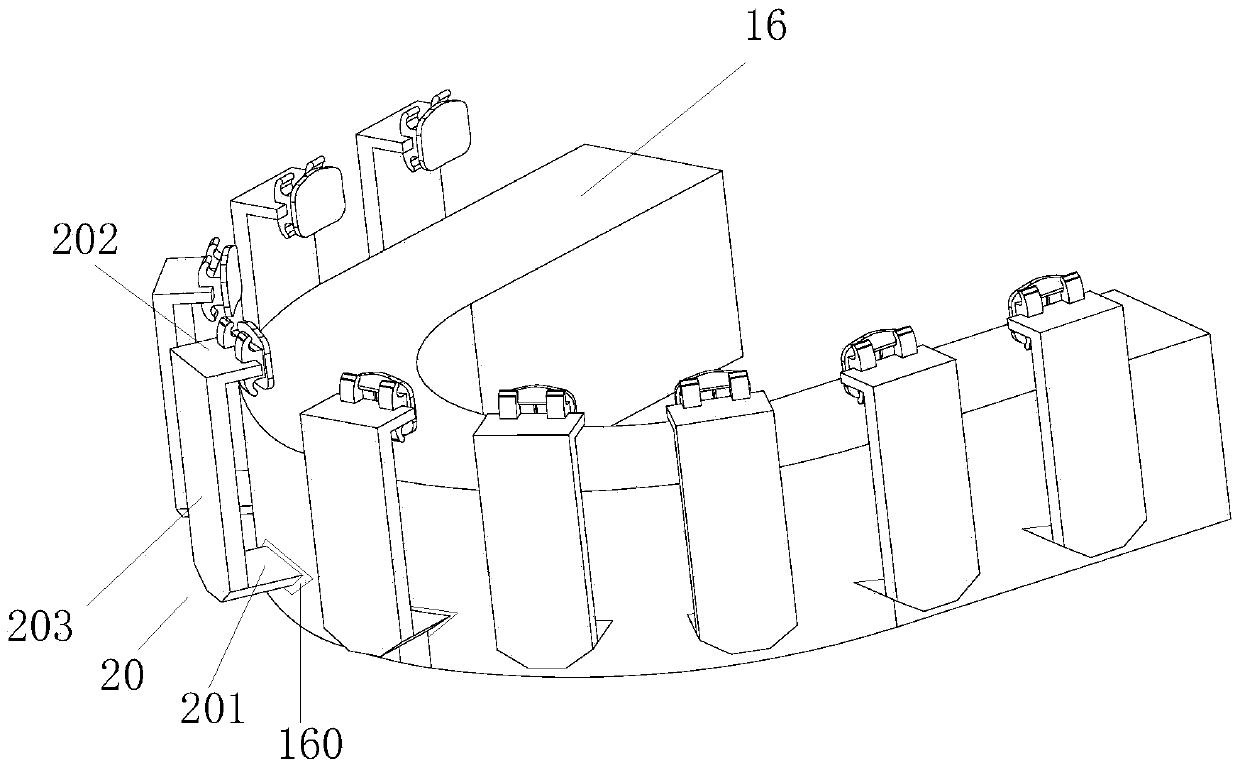

[0046] Such as figure 1As shown, the bracket bonding locator includes an occlusal plate 16 for occlusal teeth in the upper and lower oral cavity, and the occlusal plate 16 is provided with a bracket positioning frame 20 for transporting the bracket, and the bracket positioning frame 20 is inserted into the occlusal In the plate 16, the bracket positioning frame 20 slides in the occlusal plate 16 to transport and stick the bracket to the tooth surface. A chute 160 is provided in the occlusal plate 16, and the chute 160 is provided on the outer surface or the inner surface of the occlusal plate 16, and the bracket positioning frame 20 moves along the chute 160; the bracket positioning frame 20 includes a slide plate inserted in the chute 160 201 and the inserting plate 202 of the delivery bracket, the inserting plate 202 and the sliding plate 201 are connected through the connecting plate 203 . The sliding plate 201, the inserting plate 202 and the qualified connecting plate 20...

Embodiment 2

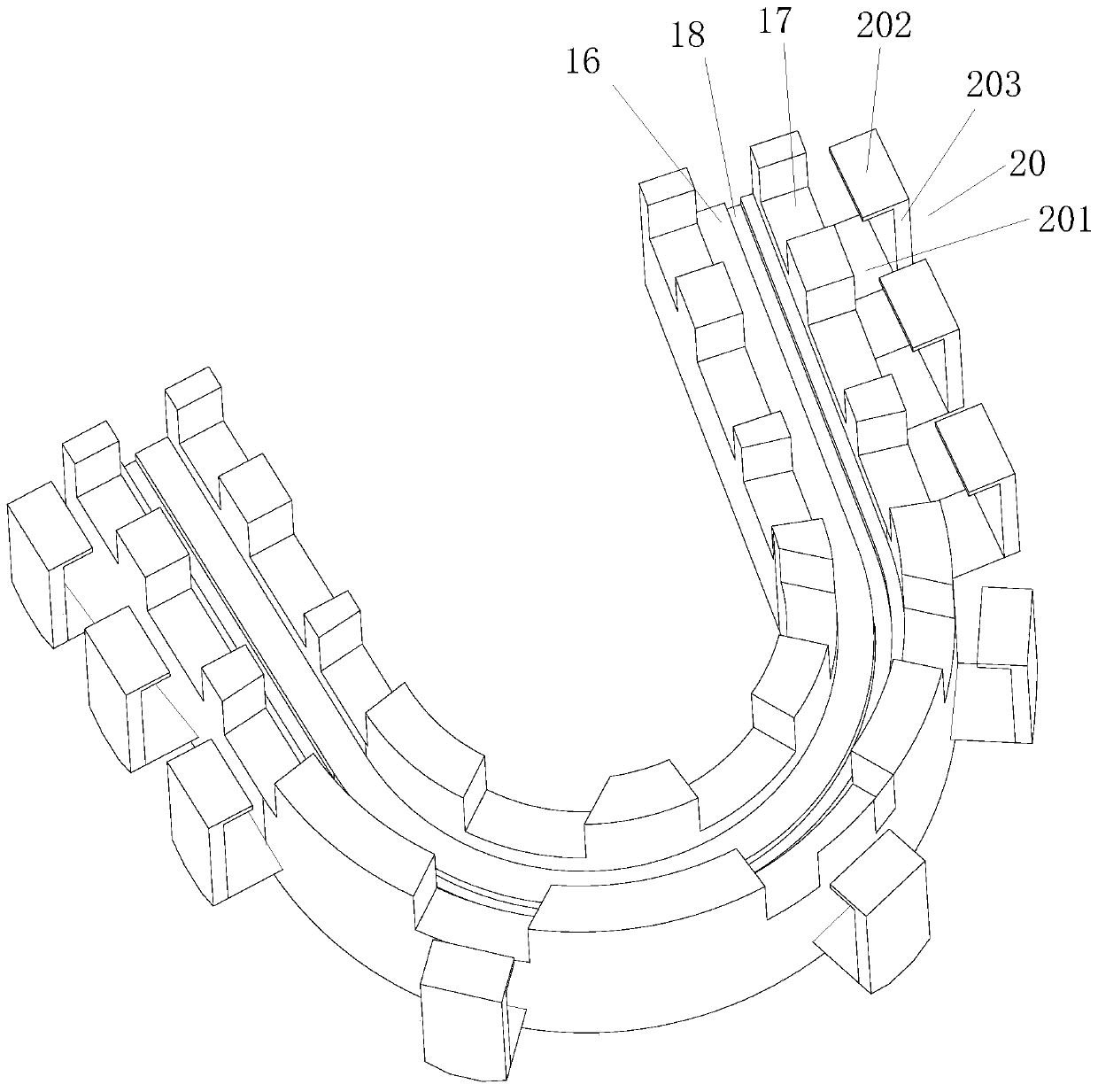

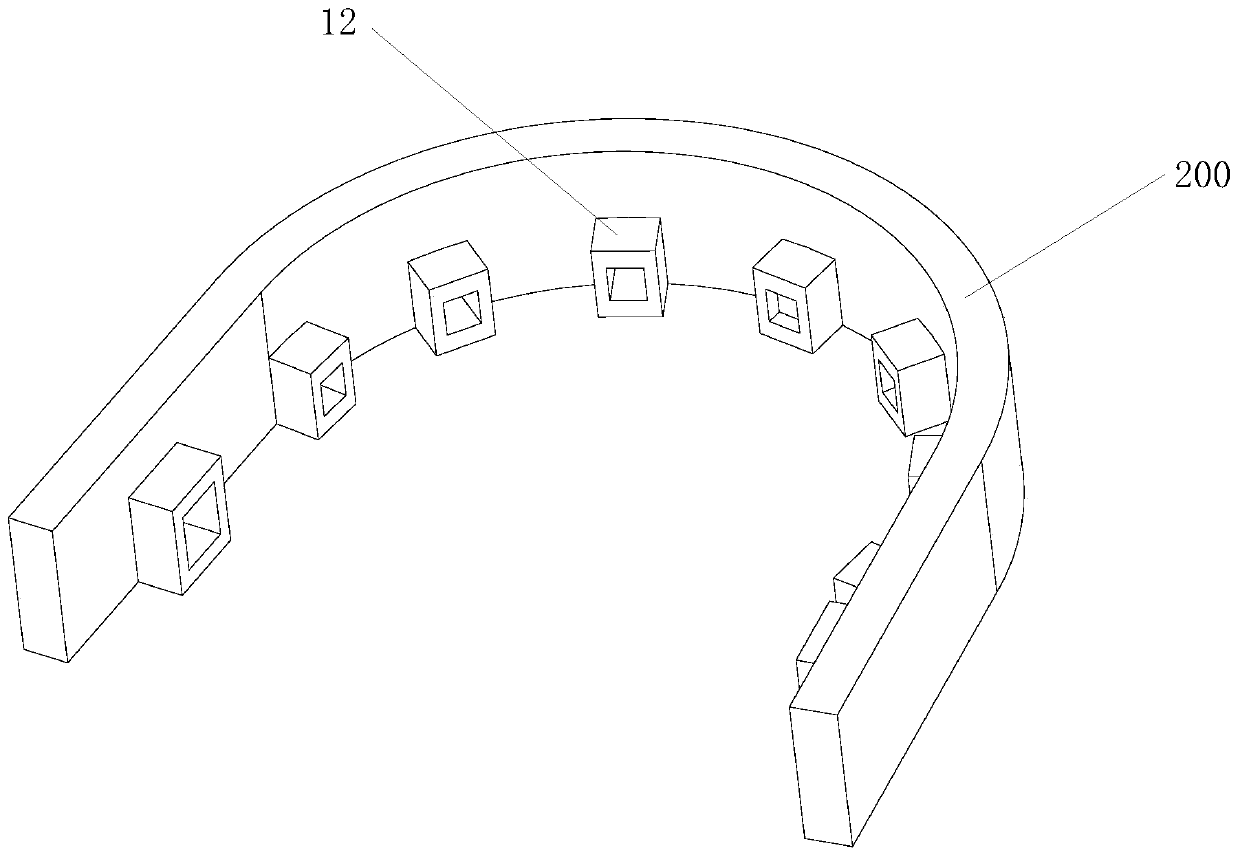

[0049] Such as Figure 2 to Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the bracket sticking positioner also includes a mounting plate 11 for fitting on the outside or inside of the orthodontic teeth, and the mounting plate 11 is arranged above the occlusal plate or / and Below, the mounting plate 11 is provided with fitting openings 17 for the brackets to pass through, and the number and positions of the fitting openings 17 are matched with the bracket positioning frame. Also include acid etching positioning plate 200, the shape of acid etching positioning plate 200 is compatible with the shape of mounting plate 11, acid etching positioning plate 200 is provided with acid etching device 12, the number and position of acid etching device 12 and the matching port 17; the acid etching positioning plate 200 is connected with the mounting plate 11 through the engagement of the acid etching device 12 and the matching port 17.

[0050] The mount...

Embodiment 3

[0063] Such as Figure 2 to Figure 4 As shown, this embodiment discloses a bracket installation and positioning method, which is applicable to the bracket bonding positioner in Embodiment 1 and Embodiment 2.

[0064] Step 1. Prepare the bracket bonding locator. The bonding locator includes: an occlusal plate 16 for occlusal teeth in the upper and lower oral cavity, the upper and lower end surfaces of the occlusal plate 16 are adapted to the occlusal surfaces of the upper and lower teeth in the oral cavity, The occlusal plate 16 is provided with a bracket positioning frame 20 for transporting the bracket; the side of the occlusal plate 16 is provided with a chute 160, and the bracket locating frame 20 includes a slide plate 201 inserted in the chute 160 and an inserting plate for transporting the bracket 202, the inserting board 202 and the sliding board 201 are connected through the connecting board 203;

[0065] Step 2. Clean the tooth surface where the bracket needs to be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com